Y Shape Check Valves

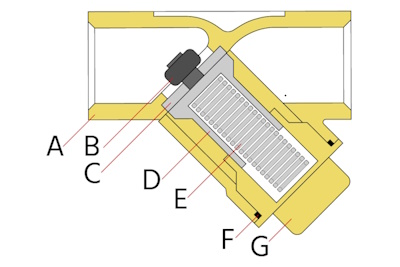

Figure 1: Y-check valve

A y-check valve is a one-way valve that prevents backflow, has a higher flow rate compared to other designs, and allows for quicker valve maintenance. This Y shaped configuration can incorporate various sealing elements, such as the flapper used in a swing check valve, the ball and cone in a lift check valve, or the spring-loaded piston in an inline check valve. This article discusses the construction, working, and applications of a Y spring check valve.

Table of contents

- When to choose a Y-check valve

- Construction

- How does a Y-check valve work

- Selection criteria

- Applications

View our online selection of check valves!

Check valve comparisons

Table 1: Comparison of Different Check Valves

| Feature/Criteria | Lift check valves | Swing check valves | Spring-loaded check valves | Ball check valves | Y-shape check valves | Sanitary check valves |

|---|---|---|---|---|---|---|

| Operation | Disc lifted by fluid flow, closes by gravity or back pressure | Hinged disc swings open with flow, closes when flow reverses | Spring mechanism compresses to open, expands to close | Ball moves away from seat to allow flow, returns to seat to block reverse flow | Y-shaped body with disc | Designed for hygienic applications, often with a spring-loaded disc |

| Advantages | Good sealing for high-pressure applications |

|

|

|

|

|

| Limitations |

|

|

|

|

|

|

| Ideal applications | Clean fluid systems with consistent flow | Water and wastewater systems with large volumes and suspended solids | Systems requiring quick response and versatile installation | Pumping systems, wastewater applications | Low-pressure steam and gas systems | Food, beverage, and pharmaceutical processing |

| Installation flexibility | Limited (horizontal only) | Limited (primarily horizontal) | High (any orientation) | Moderate (depends on design) | Moderate (depends on design) | High (often designed for easy disassembly) |

| Cost | Moderate | Low | Higher | Low to moderate | Moderate | Higher |

| Maintenance | Low to moderate, depending on debris exposure | Low | Moderate to high, due to potential spring wear | Low | Low to moderate | Moderate to high, due to hygiene requirements |

When to choose a Y-check valve

A Y-check valve is ideal for situations where maintenance schedules cannot accommodate the extended downtime associated with removing an inline check valve for cleaning or replacing worn parts. One of the primary benefits of the Y-check valve design is its accessibility. It allows for easy access to the sealing element and the valve seat for routine maintenance, without the need to remove the valve from the pipeline. This is a big advantage compared to other check valves, which usually need the process to be stopped and the valve to be removed for maintenance.

The angle seat design leads to a higher flow rate than a similar sized inline valve. Read our check valve overview article for more information on different check valve's construction and working principles.

Construction

Figure 2: An example of Y-check valve design: body (A), nut (B), disc seat (C), disc (D), spring (E), gasket (F), and bonnet (G)

The main components of a Y spring check valve are:

Body

The body of a Y-check valve (Figure 2 labeled A) encases the internal components and is constructed from robust materials such as stainless steel or brass.

- Stainless steel provides high strength and excellent corrosion resistance, making it suitable for high-pressure applications and temperatures typically ranging from -20 to 200 𐩑C (approximately -4 to 392 𐩑F).

- Brass, on the other hand, is used in lower pressure and temperature environments, generally up to 90 𐩑C (approximately 194 𐩑F), due to its good corrosion resistance and ease of machining. The body is designed to withstand the pressure from fluid flow and includes inlet and outlet ports for fluid entry and exit.

Bonnet

The bonnet (Figure 2 labeled G) in a Y-pattern check valve is positioned at an angle to the valve body, allowing access to internal components for maintenance and inspection. It is made from the same durable material as the valve body to ensure longevity and reliability, and it serves as a cover that seals and protects the internal parts of the valve.

Disc

The disc (Figure 2 labeled D) controls the fluid flow by opening when the inlet pressure is higher than the valve's cracking pressure and closing when the pressure decreases or backflow occurs.

Seat

The disc or ball rests on the seat (Figure 2 labeled C) when the valve is closed, preventing leakage and ensuring no reverse flow occurs. It is positioned between the body and the disc.

Spring

The spring (Figure 2 labeled E) assists the disc or ball in returning to the closed position when the pump is turned off or when there is a drop in pressure. The spring is made of materials like stainless steel and its strength is designed to match the valve's working pressure, allowing the disc to open easily. Read our spring loaded check valve article for more information on the design and operation of spring check valves.

How does a Y-check valve work

A Y-check valve functions by responding to pressure differences within the system.

When the inlet pressure exceeds the outlet pressure, a positive pressure difference is created. This difference generates a force that lifts the valve disc or ball towards the bonnet, allowing fluid to flow freely through the valve. The valve disc or ball remains open as long as the suction pressure is sufficiently high.

When the pump is turned off or the fluid pressure decreases, the valve spring is no longer compressed and begins to push the disc back to its seated position, effectively preventing any backward flow of fluid.

In some Y-check valve designs, there is no spring. In these models, the disc returns to the seat due to gravity or the force of backflow, effectively stopping reverse flow. Y type check valves can be installed in either horizontal positions or vertical positions. For models without a spring, vertical installations should have the flow directed upward to enable gravity to help close the valve. Always consider the flow direction indicated on the valve body.

Selection criteria

Consider the following parameters while selecting a Y-check valve:

- Connection size: The connection size must match the piping system to ensure a proper fit and prevent leaks. Connection sizes from 1/4 to 2 inches are typically used.

- Valve bore: Bore size is the internal diameter of the valve, which affects the flow rate and pressure drop across the valve. An undersized bore can restrict flow and increase pressure drop, while an oversized bore may lead to inefficient operation.

- Housing material: The housing material must withstand the operating temperature and media type. Stainless steel is suitable for harsh media and higher temperatures (-20 to 200 𐩑C), while brass is appropriate for milder, general-purpose applications (-10 to 90 𐩑C).

- Seal material: The seal material must be compatible with the media and temperature to ensure a tight seal and prevent leaks. Teflon (PTFE) is highly resistant to chemicals and suitable for a wide temperature range, while FKM is excellent for high-temperature applications and resistance to oils and fuels. Read our chemical resistance guide for more details on the compatibility of materials with different media.

Applications

Y-check valves are utilized in a variety of industries and applications, including:

- Food and beverage production: Y-check valves are ideal due to their angled design, which allows for easy cleaning and maintenance, crucial for maintaining hygiene standards.

- Fresh water supply systems: The Y-check valve's design facilitates quick access for maintenance, ensuring consistent prevention of backflow and maintaining water quality.

- Wastewater treatment: The ability to handle solids and slurries without clogging makes Y-check valves suitable for managing fluid flow in treatment processes.

- Oil and gas refineries: Y-check valves can handle high pressures and temperatures, and are suitable for the demanding conditions in refineries. They are also widely used in steam power generating plants.

- Firefighting applications: The quick access design of Y-check valves ensures reliable flow control, crucial for emergency systems where rapid response is essential.

Read our check valve applications article for more information on the general applications of different check valve types.