Air Compressor Valves: Types, Functionality, and Maintenance

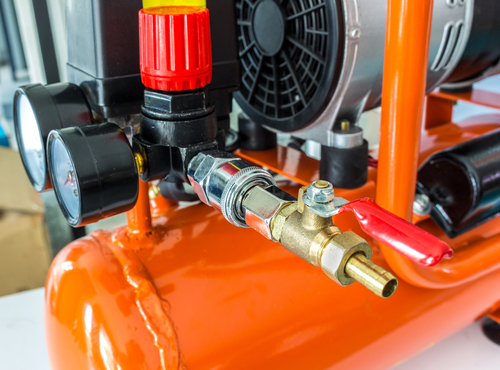

Figure 1: Air compressor ball valves

Air compressors are essential in various industries, providing compressed air for various applications. Valves play a critical role in the functioning of air compressors. Whether they are regulating the airflow, controlling pressure, or safeguarding against overpressure conditions, air compressor valves are critical for maintaining optimal operation and protecting the equipment and personnel involved. This article explores various air compressor valves' functions, features, and types of air compressor valves.

Table of contents

View our online selection of compressed air products!

Air compressor valves

Air compressor valves are categorized based on their location and function.

- Location: Inlet and outlet valves

- Function: Unloader, throttle, shutoff, drain, and pressure relief valves

Inlet valve

- Function: They allow the atmospheric air to enter the compression chamber during the suction stroke. The inlet valve opens and closes based on the pressure difference between the compression chamber and the atmosphere.

- Location: Air compressor inlet (or intake) valves are located at the compressor's air intake or suction side.

- Types: Reed valves are widely employed in compressors due to their simplicity, reliability, and efficiency. They are typically made of thin metal reeds that act as flexible flaps, opening, and closing in response to pressure differentials.

Outlet valve

- Function and location: It facilitates the release of compressed air from the compression chamber during the discharge stroke.

- Location: An air compressor's outlet (discharge) valve is situated at the outlet or discharge side of the compressor.

- Types: Reed valves, plate valves, and poppet valves

Unloader valve

- Function:Unloader valves in an air compressor, also known as minimum pressure valves or unloaders, relieve pressure from the compression chamber during unloaded or idle operation. This prevents excessive pressure buildup in the system, reducing energy consumption when the motor stops.

- Location: The location of the unloader valve in an air compressor system depends on the compressor's design. This valve is commonly found on the cylinder head in reciprocating compressors and the discharge line in rotary screw compressors. In advanced systems, the unloader valve can be integrated into the compressor control panel, allowing for electronic control based on system pressure and load demands.

- Types: Unloader valves can be mechanical or electric.

- A mechanical unloader valve works according to the pressure differential; it opens when the pressure reaches a predetermined pressure value.

- A solenoid valve is an electrically operated device that controls the amount of air that passes through a line. It shuts off, releases, or doses the flow according to the system requirements.

Figure 2: Air compressor unloader valve

Control valve

-

Function: Control valves maintain the flow rate and pressure of compressed air leaving the compressor. This ensures that the output matches the specific requirements of the downstream system and prevents pressure fluctuations, damage, or inefficiencies.

- Control valves in the inlet line regulate the amount of air entering the compressor, optimizing its capacity and performance.

- In branch or distribution lines, control valves provide tailored airflow adjustments to specific subsystems or equipment.

- Advanced systems may integrate control valves into a control panel or operator interface, enabling remote control and convenient management of flow control settings for optimal compressor performance.

- Location: Control valves are installed between the compressor and the air receiver tank or system. They are commonly installed in the inlet or the discharge line, allowing operators to adjust the flow rate and pressure before the compressed air enters the downstream system or air receiver tank.

Check valve (Non-return valve)

- Function: Air compressor check valves are one-way valves that allow the air to only move in one direction: from the compressor to the downstream system. Backflow, or flow in the reverse direction, can cause pressure fluctuations or damage the compressor.

-

Location: The configuration and placement of check valves can vary depending on the compressor system design, size, and intended application. Additionally, the number of check valves used in a compressor system may vary depending on the complexity and requirements of the system.

- They are placed at the compressor head or discharge port outlet to prevent backflow into the compressor, safeguarding it from damage and maintaining system pressure.

- In systems with an air receiver tank, a check valve is installed at the tank's inlet to allow compressed air to flow into the tank while preventing backflow.

- Check valves may also be placed downstream of treatment components to ensure the proper flow direction and prevent contamination or moisture from entering the treated air stream.

- Types: Swing, piston, and ball check valves are generally used in air compressors. Read our air check valve article for more information on check valve selection, issues, and troubleshooting in air compressors.

Shutoff valves

- Function: Shutoff valves are commonly used in air compressors to completely stop the flow of compressed air and isolate the compressor from the rest of the system. These valves serve as a means of shutting off the air supply and are primarily used for maintenance, repair, system isolation, and emergencies.

-

Location:

- At the compressor inlet, shutoff valves enable operators to close off the air intake, isolating the compressor during maintenance or when it needs to be temporarily taken out of service.

- At the compressor outlet, shutoff valves stop compressed air flow, preventing it from entering the downstream system or air receiver tank.

- In distribution lines, shutoff valves can shut off specific sections or equipment for maintenance or repairs without interrupting the system.

- Shutoff valves at the air receiver tank's inlet and outlet connections allow operators to isolate the tank from the system, controlling the flow of compressed air in and out of the tank as needed.

- Types:Ball valves are most commonly used as shut-off valves in air compressors; However, gate valves, globe valves, and butterfly valves can also be used.

Drain valves

- Function: An air compressor drain valve, also known as a condensate drain valve or compressor tank drain valve, is designed to remove accumulated moisture and condensate from the air compressor system.

- Location: The drain valve is typically located at the bottom of the air receiver tank. The exact location of the drain valve may differ based on the compressor model and configuration, so refer to the compressor's manual for precise information on the location.

Pressure relief valves

- Function:Air compressor pressure relief valves are vital for system safety. They protect the compressor, downstream equipment, and the overall compressed air system from overpressure conditions. These valves automatically open and release excess pressure when it exceeds a predetermined set point. Pressure relief valves ensure the integrity and safe operation of the compressor system by preventing equipment failure, leaks, and safety hazards caused by overpressurization.

- Location: Pressure relief valves are located at specific points in the air compressor system where pressure regulation and protection are necessary, like the air receiver tank or the compressor discharge line.

- Types: Spring-loaded, pop-off, direct-acting, and pilot-operated pressure relief valves

Notes

- Material selection: Common materials used for valve construction include stainless steel, brass, cast iron, and various alloys.

- Load and unload cycling: Air compressors often operate in load and unload cycles, where the compressor turns on and off based on the system demand. The valves should be designed to handle these frequent cycling operations without experiencing excessive wear or performance degradation.

- Air contaminants: Compressed air can contain contaminants such as dirt, oil, moisture, or particulates. Air compressor valves should be capable of handling these contaminants and preventing them from affecting valve performance or causing blockages. Look for valves with features like filters, strainers, or built-in separators to remove contaminants from the compressed air.

- Noise reduction: Air compressors can generate significant noise during operation. Valves with noise-reducing features like mufflers, silencers, or acoustic-dampening materials can help reduce noise levels and ensure a quieter working environment.

- System integration: Consider the communication protocols, electrical connections, or compatibility with automation systems, if applicable, to ensure seamless integration and control of the valves within the overall compressor system.

FAQs

How often should air compressor valves be maintained or replaced?

Valve maintenance and replacement intervals can vary depending on operating conditions, usage, and manufacturer recommendations. Regular inspection, cleaning, and lubrication are essential, and valves should be replaced if they show signs of wear or leakage.

What is the difference between air compressor pressure relief and unloader valves?

A pressure relief valve protects the system from overpressure conditions by releasing excess pressure. In contrast, an unloader valve relieves pressure from the compressor's discharge line during start-up and idle periods.

What is an air compressor cold start valve?

A cold start valve in an air compressor is an unloader valve that assists in the starting process by relieving pressure from the compressor's discharge line, making it easier to start the compressor.