Solenoid Valve Parts Guide

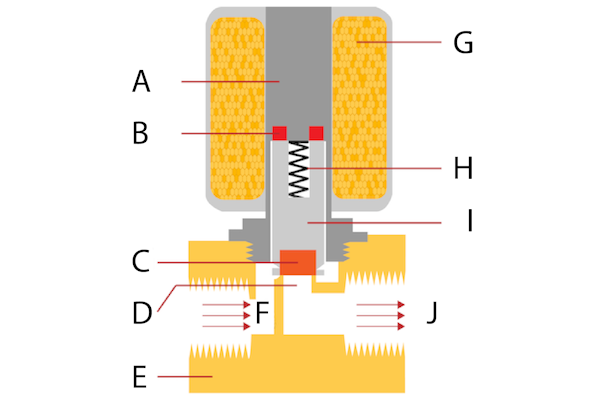

Figure 1: 2/2-way solenoid valve parts diagram: armature tube (A), shading rings (B), seal (C), orifice (D), valve body (E), inlet port (F), solenoid coil (G), spring (H), plunger (I), and outlet port (J).

A solenoid valve consists of two main components: a solenoid and a valve body. Within these components are various parts, and understanding them helps enhance the knowledge of how the valve works as a whole unit. This article discusses the parts of a 2/2-way solenoid valve and its functions. Other types of solenoid valves, like multi-port solenoid valves, share these same basic components, with only minor differences in their internal design.

The different parts of a solenoid valve work together to ensure proper operation. It's essential to install each part correctly, as missing or incorrectly installed parts can cause the valve to malfunction.

Solenoid valve parts

- Armature tube (A)

- Shading rings (B)

- Seal (C)

- Orifice (D)

- Valve body (E)

- Inlet port (F)

- Solenoid coil (G)

- Spring (H) and plunger (I)

- Outlet port (J)

- Lead wires

- Replacing solenoid valve parts

- FAQs

View our online selection of solenoid valves and buy one today!

Armature tube (A)

The armature tube is a hollow component that guides the plunger. Any flaws in the tube can restrict the plunger's movement. Dirt accumulation can also affect the plunger's movement, increasing heat and leading to valve damage.

Shading rings (B)

The shading rings prevent vibration and humming in AC solenoid coils. Read our article on understanding solenoid design and function for more details on the importance of shading rings in AC solenoid valves.

Seal (C)

The seal shuts off the valve, preventing media from flowing through it. The seal comes in contact with the medium to be controlled. Therefore, always ensure the seal material matches the chosen valve media. The seal should also be kept free from dirt to prevent the valve from partially opening and closing. Read our article on solenoid valve seal material for more information.

Orifice (D)

The orifice connects the inlet and outlet ports. The movement of the plunger restricts or allows the flow of media in and out of the valve. A solenoid valve can have one or more orifices depending on the working principle employed and the required action.

Valve body (E)

The valve body connects to the piping and contains the end of the plunger, seal, and orifice. The valve body has two openings - the inlet and outlet ports. High-grade materials like stainless steel, plastic, or brass are used for the valve body to ensure it can handle the media and resist corrosion.

The design of the valve body varies between different solenoid valve types, like direct, indirect, or semi-direct solenoid valves.

Inlet port (F)

The solenoid valve inlet connects to the pipe or hose carrying the media. The media enters the valve through the inlet port.

Solenoid coil (G)

The solenoid valve coil consists of multiple turns of enameled wire. It is made of copper and is cylindrical and hollow inside.

Spring (H) and plunger (I)

The plunger is a cylindrical piece made of ferromagnetic material that sits inside the solenoid coil. It moves up and down to control fluid flow through the valve. A spring provides the force needed to hold the plunger in its default position.

The spring and plunger work together differently depending on the valve type:

- Normally closed valves: The spring pushes the plunger down to block fluid flow. When electricity flows through the coil, it creates a magnetic field that pulls the plunger up against the spring force, opening the valve.

- Normally open valves: The spring holds the plunger in an open position, allowing fluid flow. When the coil is energized, the magnetic field pulls the plunger down against the spring force, closing the valve.

When power is removed, the spring always returns the plunger to its original position, either opening or closing the valve, depending on its design. Read our solenoid valve overview article for more details on the design, working, and types of solenoid valves.

Outlet port (J)

The fluid exits the solenoid valve through the output port. The number of outlet ports can vary depending on the type of solenoid valve.

- A 2/2-way solenoid valve has one inlet and one outlet port, allowing fluid to flow in one direction when the valve opens.

- A 3/2-way solenoid valve has three ports and two positions. It can direct fluid between different paths or mix fluids from multiple sources.

Lead wires

When the valve is energized, the lead wires connect it to the power supply, either directly or via a connector. The current flow stops when the power is switched off.

Figure 3: Lead wires in a solenoid valve

Replacing solenoid valve parts

Certain solenoid valve parts wear out over time and should be replaced:

- Seals: Replace the seal when fluid leaks or the valve doesn't close completely.

- Spring: Replace the spring if the valve response becomes sluggish or inconsistent.

- Plunger/armature: Replace if valve fails to open or close properly.

- Solenoid coil: Replace the coil if the valve doesn't energize. Use a multimeter to check the continuity of the coil and verify if it works.

It's a good practice to keep solenoid valve revision kits handy. The revision kits contain all essential wear parts for solenoid valves, like the plunger, seal, spring, o-ring, membrane, and membrane spring. Therefore, you do not need to replace the entire valve if a particular part fails. The revision set kit is highly cost-effective compared to a whole valve unit. Read our solenoid valve maintenance article for a step-by-step guide on maintaining solenoid valves.

FAQs

How does a solenoid valve coil work?

When energized, a solenoid valve coil generates a magnetic field. This field pulls the plunger to open or close the valve, controlling fluid flow.

What is a plunger in a solenoid valve?

A solenoid plunger, commonly called a piston, moves up and down to open or close the valve.

What is a solenoid valve used for?

A solenoid valve is an electrically controlled valve used to release, shut off, distribute or mix fluids in common industrial applications.