Flow Meters - How They Work

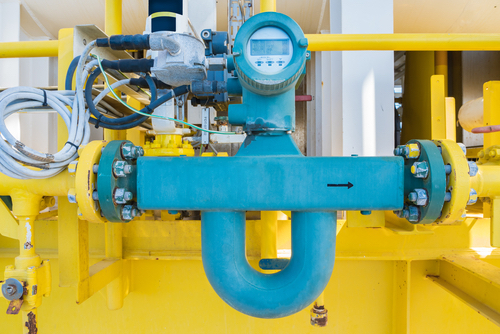

Figure 1: An electromagnetic flow meter on a water pipeline.

Flow meters provide fast and accurate flow rates so operators can determine how optimally the system is operating. Due to the variety of flow meters available, it's important to understand how they work and their ideal applications to choose the proper flow meter. This article overviews the different types and provides guidance on what to pay attention to when choosing a flow meter.

Table of contents

- What is a flow meter?

- Why are flow meters used?

- Volumetric flow meters

- Mass flow meters

- Selection criteria

- Applications

- FAQs

View our online selection of SAW (Surface Acoustic Waves) flowmeters!

What is a flow meter?

Flow meters measure a fluid's volume or mass to determine the flow rate. There are many flow meter types, each with its own working principle. The various types also vary in accuracy and system requirements. Flow meters can operate in closed systems, such as piping systems, and open systems, such as channels and rivers. There are several different ways to read a flow meter. For example, electronic flow meters can be read using a digital screen or send data to a piece of software. Some flow meters have dials and an analogue display, while others use a floating element in a glass tube similar to a graduated cylinder.

Why are flow meters used?

The main purposes of using flow meters include:

- Monitoring: Operators can ensure proper operation and efficiency by using a flow meter to monitor flow rates and masses.

- Leak detection: Monitoring flow rates can help to detect leaks in pipelines, minimizing wastage and potential environmental damage.

- Safety: Flow measurement, along with proper pressure gauges usage, can help prevent overpressure in pipelines. Also, flow measurement helps to maintain proper flow rates for cooling in industrial processes.

- Billing: Accurate measurement of fluid flow rates and masses is necessary for billing and regulatory purposes in many industries.

- Environmental compliance: Flow meters can measure emissions, effluent discharges, and water usage, helping industries comply with environmental regulations.

Volumetric flow meter types

Several types of volumetric flow meters are available, and each operates based on different principles. For an in-depth overview, please read our volumetric flow meter article. However, here are a few common types:

- Surface acoustic wave (SAW) flow meters: SAW flow meters (Figure 2) are non-intrusive devices that use surface acoustic waves to measure the flow rate of a fluid. They operate by analyzing the changes in wave propagation caused by the fluid flow. Read our Burkert 8098 flow meter article for more details on the operation, working principle, and other features of SAW flow meters.

- Differential head: Measures pressure difference across an obstruction (e.g., orifice plates, venturi meters).

- Differential area (Rotameters): Uses a float in a tapered tube to visually display flow rate.

- Turbine flow meters: Measures flow velocity by the rotation of a rotor with blades or vanes.

- Ultrasonic flow meters: Calculates flow rate by measuring the time difference of transmitted ultrasonic signals.

- Vortex flow meters: Determines flow rate by measuring the frequency of vortices created by a bluff body in the flow stream.

- Electromagnetic flow meters: Utilizes electromagnetic induction to measure voltage induced by a conductive fluid flowing through a magnetic field.

- Paddle wheel flow meters: Utilize a spinning wheel with vanes to measure the flow rate as the fluid pushes against the paddle blades.

Figure 2: Burkert 8098 flow meter

Mass flow meters

There are two types of mass flow meters: thermal mass flow meters and Coriolis mass flow meters. They measure the mass of material flow through the meter. They are mainly intended to measure gasses but can measure liquids in some applications.

Thermal mass flow meters

Thermal flow meters use a heat source to introduce heat to the flow and measure how the temperature changes using sensors or how much energy is necessary to keep the heat source constant. The heat source can go directly into the flow or be external to the meter.

Coriolis mass flow meters

Coriolis mass flow meters have a rotating component that introduces a Coriolis force to the flowing media. The flow meter can detect the fluid's resulting angular momentum and is proportional to the fluid's mass.

Figure 3: A Coriolis flow meter measuring oil and gas fluids.

Selection criteria

Consider the following criteria when selecting a flow meter:

- Connection size: When connecting a flow meter to a pipe, ensure the same sizes.

- Connection type: There are different connection types available, including flanged, threaded, and clamp connections.

- Pressure and temperature: Ensure the flow meter can handle the system's normal pressure and temperature conditions.

- Fluid type: Make sure the flow meter can handle the fluid, whether liquid or gas. Understand the fluid's properties, such as density, viscosity, and conductivity.

- Accuracy and repeatability: Different applications require different accuracies. A flow meter's accuracy is expressed in percentages, such as 1%. The lower the percentage, the higher the accuracy.

- Installation location: Different flow meters have different requirements on where they can be installed in a system. Be sure to read installation instructions carefully. Read our flow meter installation article for more information on issues during fluid measurement and proper mounting techniques for the flow meter.

Applications

Volumetric and mass flow meters measure the flow rate of media moving through the system. Both can be used to measure liquids and gasses in specific applications. Still, volumetric flow meters are generally more suitable for liquids, and mass flow meters are more suitable for gasses.

Volumetric flow meters

- Chemical and pharmaceutical industries: Flow meters ensure accurate dosing, blending, and reaction processes by measuring the flow of chemicals, solvents, and other pharmaceutical ingredients.

- Oil and gas industry: Precise flow measurements are necessary for billing and regulation in the oil and gas industry.

- Beverage industry: Proper beverage portioning and mixing can be accomplished using flow meters.

- Wastewater treatment: Water and sewage treatment plants and distribution networks use flow meters to measure clean water, wastewater, or sludge flow.

- Irrigation and agriculture: Flow meters help farmers optimize and conserve water resources.

Mass flow meters

- Natural gas distribution: Mass flow meters accurately measure natural gas flow at transfer stations for billing, allocation, and compliance reasons.

- Semiconductor manufacturing: Mass flow meters control and measure the specialty gasses and process chemicals used in semiconductor manufacturing.

- HVAC: Mass flow meters measure the airflow and other gasses in HVAC systems.

- Combustion control and emissions monitoring: Mass flow meters measure the flow of combustion air, fuel gasses, and exhaust gasses in industrial burners, boilers, and engines.

FAQs

How does a flow meter calculate flow?

There are many different types of flow meters and they operate differently. For example, some measure differential pressure while others measure fluid conductivity.

What are the two types of flow meters?

The two types of flow meters are volumetric flow meters and mass flow meters.