Volumetric Flow Meter - Working, Types, and Selection

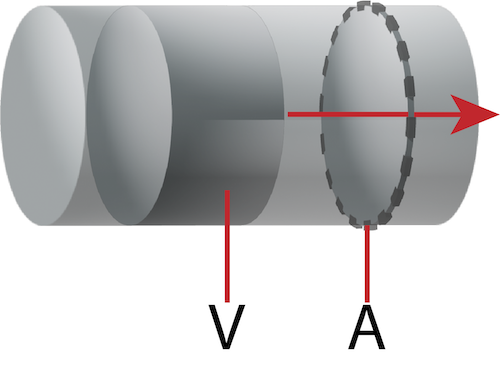

Figure 1: Volumetric flow meter

Volumetric flow meters measure the volume of fluid passing through a specific point in a system per unit of time. The value is typically expressed in units such as liters per minute or cubic meters per hour. Measuring the flow rate allows for more precise monitoring and control of flow processes within a variety of industries. This article explores the various types of volumetric flow meters and the general selection criteria.

Table of contents

- Volumetric flow

- Volumetric flow meter

- Components

- Volumetric flow meter types

- Selection criteria

- FAQs

View our online selection of SAW (Surface Acoustic Waves) flowmeters!

Volumetric flow

The volumetric flow rate is the amount of fluid (Figure 2 labeled V) that passes through a particular area (Figure 2 labeled A) within a given period. It quantifies the fluid's three-dimensional space as it flows through the device. Divide the fluid volume by the time it takes to pass through to get the volumetric flow rate.

Volumetric flow meter

A volumetric flow meter measures the volumetric flow rate. Volumetric flow meters are commonly used in various industries, such as oil and gas, water and wastewater, chemical processing, and pharmaceuticals. They are crucial for monitoring and controlling fluid flow in pipelines, ensuring accurate measurements for process optimization, billing purposes, and maintaining system efficiency.

For example, consider a flow meter installed on a water pipe that measures an average velocity of 1.5 meters per second. If the pipe's cross-sectional area is 0.25 square meters, the flow meter will calculate the volumetric flow rate as 0.375 cubic meters per second (1.5 m/s * 0.25 m²). Read our flow meters article for more information on the definition and types of flow meters.

Figure 2: Representation of fluid volume (V) and area of cross-section (A).

Components

The various components in a volumetric flow meter measure and provide information about the fluid flow, allowing for monitoring, control, or further analysis. These components can vary depending on the flowmeter type; the general components in a volumetric flow meter are discussed below:

- Primary element: The primary element is the part of the flowmeter that interacts directly with the fluid flow and creates a measurable effect. It may include various components such as orifices, nozzles, venturis, or flow tubes. These elements cause a pressure drop or other physical changes in the fluid, which can be correlated to the volumetric flow rate.

- Transducer: The pressure transducer converts the physical parameters generated by the primary element into an electrical signal, typically using sensors (like pressure or temperature sensors).

- Transmitter: The transmitter receives the electrical signal from the transducer, processes it, and provides useful flow measurement information. It may perform functions like amplification, compensation for environmental factors, and conversion into an output format for display or transmission.

- Display/Indicator: The display or indicator provides a visual representation of the measured flow rate. In some advanced flowmeters, the display may provide additional information such as flow rate trends, alarms, diagnostics, or communication capabilities.

- Communication Interface: Many modern flowmeters include communication interfaces to transmit the flow data to external devices or control systems. These interfaces can be analog (4-20 mA), digital (like RS-485 or Modbus), or wireless (like Bluetooth or Wi-Fi), allowing integration automation systems.

Volumetric flow meter types

Surface acoustic wave (SAW) flow meters

SAW flow meters (Figure 1) are non-intrusive devices that use surface acoustic waves to measure the flow rate of a fluid. They operate by analyzing the changes in wave propagation caused by the fluid flow. SAW flow meters offer advantages such as non-intrusiveness, high accuracy, and low maintenance requirements. They find applications in food processing, water management, chemical processing, and oil and gas. Read our Burkert 8098 flow meter article for more details on the operation, working principle, and other features of SAW flow meters.

Differential head flow meters

Differential head flow meters measure the flow's pressure difference across an obstruction. They take advantage of Bernoulli's Principle, which states that the differential pressure across the obstruction is proportional to the flow rate's square. The main styles of differential head flow meters are orifice plate, venturi, and Annubar.

- Orifice plates: Orifice plate differential flow meters have an obstruction formed by a thin plate with a precisely measured orifice. The orifice causes a pressure drop in liquid or gas media flowing through it.

- Venturi: Venturi meters have a tapered tube that reduces the flow area, increasing flow velocity and decreasing pressure.

- Annubar: Annubar flow meters have pressure-sensing ports along a tube or rod in the flow stream. Differential pressure is determined by measuring pressure at different ports.

Differential area (rotameters)

Rotameters have a tapered tube, similar to venturi differential head flow meters, to cause a pressure drop in the flow meter. They also have a float balanced by the flowing fluid's upward force. The float's position indicates the flow rate.

Mechanical flow meters

Mechanical or turbine flow meters differ from electronic flow meters because they have a rotor with blades or vanes in the flow's path. The flow spins the rotor at a speed proportional to the flow velocity. Read our article on paddle wheel flow meters to learn more.

Ultrasonic flow meters

Ultrasonic flow meters transmit ultrasonic signals through the media to measure the time necessary for the signals to travel upstream and downstream. The transit time difference allows for calculating the flow rate. These meters are non-intrusive and are suitable for a variety of fluid types.

Figure 3: An ultrasonic flow meter

Vortex flow meters

Vortex flow meters use the von Kármán effect. Within the meter is a blunt, raised area. As the fluid flows past this area, alternating vortices are created. A flexible sensor tab in the flow meter bends and flexes to measure the frequency of the vortices. The frequency of vortices is proportional to the flow rate. These flow meters are highly accurate and suitable for a range of fluids.

Magnetic flow meters

Magnetic flow meters take advantage of Faraday's law of electromagnetic induction. This flow meter creates a magnetic field. When conductive fluid flows through the magnetic field, an electromotive force (voltage) proportional to the flow rate is produced. These flow meters are best for conductive fluids like water, wastewater, and chemicals. They have relatively small pressure drops.

Figure 4: A magnetic flow meter

Selection criteria

Consider the following general criteria while selecting a volumetric flow meter:

- Connection size and type: Ensure compatibility with the connection port size and type (clamp, flange, or threaded) to ensure proper installation.

- Industry requirements and approvals: Flow meters come with various certifications like Food grade (for the food and beverage industry), ATEX Zone 2 and ATEX Zone 22 (for explosive environments), UL, and ECEx Zone 2 and 22 (international standard for explosive environments).

- Electrical requirements: Verify compatibility with the specified voltage range and connection types (cable glands and plug type) to ensure proper electrical integration.

- Display and transmitter type: Consider whether a display is required for on-site flow rate monitoring. Also, ensure the transmitter supports the required communication protocols, data formats, and connectivity options for seamless integration with the existing control or monitoring system.

- Operating parameters: Ensure the flow meter can operate within the required temperature and pressure ranges.

- Communication protocol: Assess compatibility with the specified communication protocol (like büS) to ensure seamless integration with the control or monitoring system.

Read our flow meter installation article for more information on issues during fluid measurement and proper mounting techniques for the flow meter.

FAQs

How to choose the right flow meter for my application?

When selecting a flow meter, consider the fluid properties, flow range, desired accuracy, installation requirements, and environmental conditions.

Can a flow meter be installed in an existing pipeline?

Yes, flow meters can be retrofitted into existing pipelines with proper considerations for installation requirements, pipe dimensions, and flow profiles to ensure accurate measurements.