HVAC Ultrasonic Flow Sensor - How They Work

Figure 1: An HVAC ultrasonic flow sensor

Ultrasonic flow sensors use ultrasonic technology to measure flow rate in a pipe without needing to contact the fluid physically. They optimize efficiency and functionality, catering to a variety of applications, making them excellent air flow sensors for HVAC applications. This article overviews the significance of ultrasonic flow sensors in HVAC applications, outlining their suitability across different scenarios, the intricacies of their design and operating principles, and the essential criteria for selecting the appropriate sensor for specific HVAC needs.

Ultrasonic flow sensor HVAC applications

Ultrasonic flow sensors are favored in HVAC applications for their accuracy, reliability, and non-intrusive measurement capabilities. These characteristics make them indispensable tools for maintaining HVAC systems' efficiency, performance, and longevity.

-

Chilled water systems

- Application: Monitoring chilled water flow to various parts of a building for cooling.

- Why suitable: Ultrasonic flow sensors provide accurate flow measurements without obstructing the water path, ensuring optimal cooling performance without pressure drops.

-

Hot water heating systems

- Application: Measuring the flow of hot water used for heating purposes.

- Why suitable: Their non-invasive nature allows continuous operation without the risk of sensor corrosion or degradation due to hot water, ensuring long-term reliability.

-

Energy management

- Application: Collecting data on water flow rates to optimize energy usage in heating and cooling applications.

- Why suitable: Ultrasonic sensors can accurately measure flow rates in real-time, providing valuable data for energy-saving strategies without interrupting system operation.

-

Leak detection

- Application: Identifying leaks in pipes to prevent energy loss and damage to the system.

- Why suitable: They can detect changes in flow rate that may indicate a leak, offering a non-intrusive method to maintain system integrity.

-

System balancing

- Application: Ensuring that water flow is evenly distributed throughout the HVAC system for consistent temperature control.

- Why suitable: The precision of ultrasonic flow sensors allows for fine-tuning of flow rates, facilitating effective system balancing without direct contact with the fluid.

View our online selection of hvac flow meters!

Ultrasonic flow sensor design and operating principle

The design of an ultrasonic flow sensor combines precision, efficiency, and versatility. At its core, the sensor employs ultrasonic technology to measure the flow rate of a fluid within a pipe without any physical contact with the fluid itself. This section covers the key components and principles that define the ultrasonic flow sensor's design. Learn about other flow meter designs in our flow meter overview article.

Key components

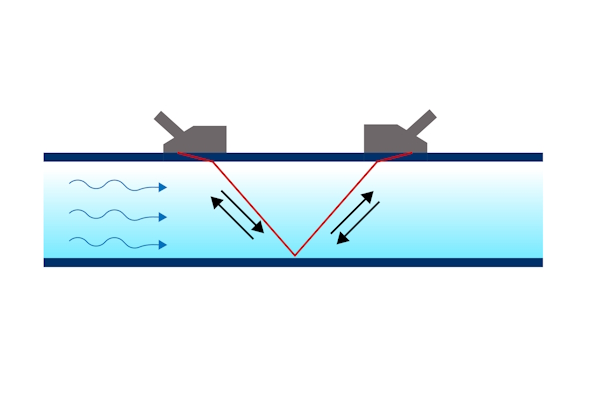

- Transducers: The transducers emit and receive ultrasonic waves. These are typically piezoelectric transducers that convert electrical energy into ultrasonic sound waves and vice versa. Positioned on opposite sides of the pipe, one transducer acts as the transmitter, sending ultrasonic waves through the fluid, while the other serves as the receiver, capturing the waves after they have traversed the fluid.

- Electronic circuitry: This component processes the signals from the transducers. It calculates the time it takes for the ultrasonic wave to travel with the flow of the fluid versus against it. The difference in these times is directly related to the flow rate of the fluid.

- Display and interface: Ultrasonic flow sensors typically have digital displays and interfaces for easy reading and configuration. Users can view flow rates in real-time and adjust settings as needed for specific applications.

- Temperature sensor: The temperature sensor collects fluid temperature data to compensate for temperature effects on the flow rate.

- Enclosure: The enclosure houses the electronic components and provides protection against environmental factors. It is designed to withstand the conditions of the environment in which the sensor operates, whether it be outdoor weather conditions or the harsh environments of industrial applications.

Operating principle

The operation of an ultrasonic flow sensor is based on the time-of-flight principle. This method involves measuring the time it takes for an ultrasonic signal to travel a known distance with the flow of the fluid compared to against the flow. When the fluid is moving, the transit time for the ultrasonic wave traveling downstream (with the flow) is shorter than the time for the wave traveling upstream (against the flow). The difference in these transit times is proportional to the flow rate of the fluid.

Figure 2: The ultrasonic air flow sensors send signals back and forth to measure the time it takes for the signal when it goes with the flow and when it goes against the flow.

Selection criteria

- Fluid type and composition: Ensure compatibility with the fluid (e.g., water, water-glycol mixtures) and its characteristics (particulates, bubbles).

- Flow rate range: Choose a sensor that covers the expected minimum and maximum flow rates accurately.

- Pipe size and material: Match the sensor to the pipe's size and material for accurate measurements.

- Temperature and pressure range: The sensor should operate effectively within the system's temperature and pressure conditions.

- Accuracy requirements: Select a sensor with the necessary accuracy and repeatability for the application.

- Installation and maintenance: Opt for sensors that are easy to install and maintain, considering clamp-on vs. inline options.

- Output and communication options: Ensure the sensor's output signals and communication protocols are compatible with the control systems.

- Environmental conditions: The sensor should withstand the operating environment, including moisture, dust, and potential chemical exposure.

- Power supply: Verify the sensor's power requirements match the available sources.

- Budget and cost of ownership: Consider both the initial cost and the long-term expenses related to operation and maintenance.

FAQs

What is an HVAC ultrasonic flow sensor?

An HVAC ultrasonic flow sensor measures flow rates using ultrasonic waves, offering non-intrusive, accurate readings for air and gas in HVAC systems.

How does an ultrasonic flow sensor work?

An ultrasonic flow sensor has two transducers that send and receive ultrasonic waves. These measure the speed of wave travel with the fluid flow and against the fluid flow.

How accurate is an ultrasonic flow meter?

Ultrasonic flow meters are highly accurate, typically with less than 1% error.

Can ultrasonic flow sensors detect both air and gas flow in HVAC systems?

Yes, ultrasonic gas flow sensors are versatile, capable of accurately measuring both air and gas flow rates in various HVAC applications.