Electromagnetic Flow Meter - How It Works

Figure 1: An electromagnetic flow meter operating in a power plant.

Electromagnetic flow meters are used to measure conductive liquid in a system and have high accuracy. The uniformity and sophistication of their design enable a wide range of applications, from industrial process control to environmental monitoring. This article covers their design, operating principle, advantages, and applications.

Table of contents

- Design

- Operating principle

- Electromagnetic flow meter advantages

- Electromagnetic flow meter applications

- FAQs

Design

Read our article on flow meter types for an overview of the different flow meter designs.

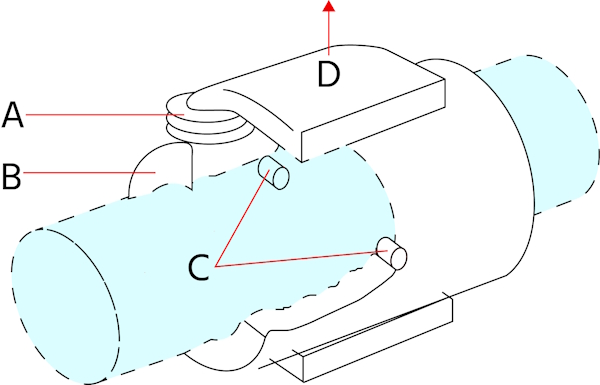

Depending on the manufacturer, the electromagnetic flow meter design can vary. However, as seen in Figure 2, an electromagnetic flow meter's construction has the following core components:

- Magnetic coils (A): Create a steady magnetic field perpendicular to the flow of the liquid. The magnetic coils must be designed to provide a uniform magnetic field across the entire cross-section of the flow tube for accurate measurements.

- Flow tube (B): The main body of the flow meter where the conductive fluid passes through. The flow tube's material must be non-conductive and chemically compatible with the process fluid to prevent corrosion and buildup. Common materials include stainless steel lined with PTFE or other non-reactive substances.

- Electrodes (C): Positioned oppositely across the flow tube, these capture the induced voltage proportional to the flow rate. Electrodes are typically made from materials such as stainless steel, Hastelloy, titanium, or platinum, chosen based on their resistance to corrosion and ability to maintain conductivity with the measured fluid.

- Converter (D): Processes the electrode voltage signal and converts it to a flow rate value. The converter's design is critical as it must filter electrical noise and compensate for variations in temperature, fluid properties, and flow profile.

Figure 2: An electromagnetic flow meter has the following key components: magnetic coil (A), flow tube (B), electrodes (C), and converter (D).

Operating principle

The operating principle of an electromagnetic flow meter is based on Faraday's Law of Electromagnetic Induction, which states that a voltage will be induced when a conductor moves through a magnetic field.

- Magnetic field generation: Electromagnets placed on opposite sides of the flow tube generate a steady and uniform magnetic field that permeates the flow tube and the liquid passing through it.

- Conductive liquid: The fluid being measured must be conductive. The liquid contains charged ions that can respond to a magnetic field.

- Induced voltage: According to Faraday's Law, the movement of the conductive liquid through the magnetic field induces a voltage. This voltage is directly proportional to the velocity of the liquid moving through the field. The faster the liquid flows, the greater the induced voltage.

- Electrode measurement: To capture the induced voltage, the flow meter has a pair of electrodes in contact with the liquid. These electrodes are positioned at right angles to both the magnetic field's direction and the liquid's flow. They detect the voltage induced in the fluid and transmit this signal to the flow meter's electronic circuitry.

- Flow rate calculation: The electronic circuitry processes the voltage signal received from the electrodes. Since the induced voltage is proportional to the flow velocity, and the cross-sectional area of the pipe is known, the flow rate can be calculated using the formula Q = A * v, where Q is the flow rate, A is the cross-sectional area of the pipe, and v is the average flow velocity.

- Output signal: The flow meter converts the calculated flow rate into an output signal that can be used for various purposes, such as display on a local readout, transmission to a control system, or recording by a data acquisition system.

Electromagnetic flow meter advantages

Electromagnetic flow meters have the following advantages:

- They have no moving parts, which leads to low maintenance and a long service life.

- They can measure the flow of dirty, corrosive, or abrasive liquids.

- They provide high accuracy and repeatability over a wide flow range. An electromagnetic flow meter's accuracy is approximately ±0.5% of the flow rate or better. Learn more about this topic in our electromagnetic flow meter calibration article.

- They cause no pressure drop in the flowing fluid.

Electromagnetic flow meter applications

Electromagnetic flow meters are versatile and can be applied across numerous industries, including water and wastewater treatment, chemical processing, food and beverage production, pharmaceuticals, and mining.

-

Water and wastewater management

- Measurement of clean water flow for municipal distribution

- Monitoring of wastewater discharge to ensure environmental compliance

- Flow measurement in sewage treatment plants for process control and efficiency

-

Chemical and pharmaceutical industries

- Precise dosing of fluids during chemical reactions

- Batch control in the production of pharmaceuticals

- Measurement of corrosive liquid flow without contact with moving parts, minimizing maintenance

-

Food and beverage sector

- Flow measurement in the production of beverages (e.g., beer), ensuring consistency and quality control

- Monitoring of liquid ingredients in food processing for accurate recipe formulation

- CIP (Cleaning-In-Place) systems to verify the flow rates of cleaning agents

-

Pulp and paper industry

- Measurement of pulp slurry flow to control the paper production process

- Management of chemical additives required during paper manufacturing

- Effluent handling and treatment processes

-

Mining and mineral processing

- Slurry flow measurement to optimize the extraction and processing of minerals

- Management of chemical dosing for separation processes

- Control of water usage in various stages of mineral processing

-

Agriculture and irrigation

- Monitoring water distribution for irrigation systems, aiding in water conservation

- Management of nutrient and fertilizer application through fertigation systems

- Measurement of water flow in aquaculture facilities to maintain optimal environments for aquatic life

Figure 3: Electromagnetic flow meters suit various industries, including mining, pulp and paper, water and wastewater management, and more.

Disadvantages of electromagnetic flow meters

- Non-conductive fluids: Electromagnetic flow meters cannot measure the flow rate of non-conductive fluids.

- Fluid conductivity requirements: The fluid's conductivity must exceed a minimum amount for the flow meter to function correctly. Check the manufacturer's data sheets to determine the specific conductivity level.

- Flow profile: Electromagnetic flow meters require a fully developed flow meter. Obstructions, bends, or an inadequate straight run of pipe upstream and downstream of the sensor can lead to measurement errors.

- Flow tube conditions: The insulating liner of the flow tube must be intact and free from damage or build-up. Any compromise in the liner integrity, such as scaling, pitting, or fouling, can negatively impact performance and may lead to inaccurate flow readings.

- Electrical interference: External electromagnetic fields can interfere with the operation of the flow meter. Interference may stem from nearby equipment, such as motors or variable frequency drives, and can cause signal noise or false readings. Shielding and proper grounding are necessary to mitigate these effects.

- Limited use in gas and steam applications: As electromagnetic flow meters are designed for measuring liquid flow, they are not suitable for gas or steam applications. The lack of electrical conductivity in these media prevents the generation of a measurable induced voltage.

- High upfront costs: Compared to some mechanical flow meters, electromagnetic flow meters can have higher initial costs due to their sophisticated electronic components and construction materials. However, this is often offset by lower maintenance costs and the longevity of the device.

- Temperature and pressure limitations: Although electromagnetic flow meters can handle a wide range of temperatures and pressures, extreme conditions can exceed the operational limits of standard sensors and liners. Specialized meters are required for very high temperatures or pressures, which may increase costs and limit options.

Figure 4: Electromagnetic flow meters must be installed with a straight flow path.

FAQs

How does an electromagnetic flow meter work?

An electromagnetic flow meter uses a magnetic field and electrodes to measure the flow rate of fluid through the flow meter.

What is the difference between an electromagnetic flow meter and an ultrasonic flow meter?

An electromagnetic flow meter measures flow of a conductive fluid using magnetic flux and an ultrasonic flow meter measures sound moving through a fluid to measure flow rate.