Water Check Valves

Figure 1: Check valve for water

A water check valve ensures that water only flows in the desired direction. Stopping backflow can prevent contaminated water from mixing with drinking water, water pumps from running dry, water waste, flooded basements, and more. This article explores the main applications of check valves for water and their selection criteria.

Table of contents

- Water check valve materials

- Check valve for water supply

- Swimming pool check valves

- Check valves in a recirculation system

- Selection criteria

- FAQs

View our online selection of check valves!

Water check valve materials

The most common check valve body materials are brass, stainless steel, and plastic:

- Brass: Suitable for general-purpose applications. Brass is durable, corrosion-resistant, and suitable for moderate temperatures. However, it is not ideal for highly corrosive environments.

- Stainless steel: Extremely durable, corrosion-resistant, and handles high temperatures and pressures. But, stainless steel is costly and heavier compared to other materials.

- Plastic: Lightweight, cost-effective, corrosion-resistant. However, plastic is less durable and unsuitable for high temperatures and pressures.

Seal material options include EPDM, FKM, NBR, and more. Read our chemical resistance guide to learn more about the compatibility of these materials with different media.

Common applications and their materials

- Drinking water: Drinking water requires a careful selection of materials; standard options include lead-free brass, stainless steel, and FDA-approved polypropylene.

- Well water: Common materials include plastic, brass, and stainless steel.

- Swimming pool: Check valves are usually PVC and compatible with plastic piping.

- Hot water recirculation system: Brass and stainless steel are excellent material options for a check valve.

Read our check valve materials article for more details on the housing and seal options available for check valves.

Check valve for water supply

Backflow preventer vs check valve

Backflow preventers and check valves have the same function and are often mistaken for the same device. However, backflow preventers are ideal for high-risk applications requiring no contamination of drinking water. While check valves can function well, they cannot provide the safety measures backflow preventers do. Read more in our article on backflow preventers versus check valves.

Drinking water

To avoid contamination, a backflow preventer is necessary when a building is connected to the municipal drinking water supply. If the water pressure drops, it can cause water to flow back towards the supply, risking contamination of the potable water.

When deciding between valves for a potable water supply application, it's essential to ensure that the valves in question meet the requirements of a regulatory body. Specific requirements vary around the world. Here are a few examples of regulatory institutions:

- Netherlands: KIWA Water Mark

- North America: National Sanitation Foundation

- France: Attestation de Conformite Sanitaire

- Germany: KTW-W270

- Great Britain: Water Regulations Advisory Scheme

Well water

A well water system might require a backflow preventer. Always look up the local regulations before deciding whether or not to install one.

Check valves serve essential functions in well water plumbing systems. First, a water well check valve can keep the water pump primed. At least one check valve before the pump's intake, whether it is a foot valve or an inline check valve, ensures that water stays in the pump and piping when the pump shuts off. Without this water, the pump can burn out when it turns on and operates for longer than a minute.

Second, check valves in well plumbing reduce the effects of water hammer, upthrust, and backspin. These three phenomena occur when water is allowed to flow freely back into the well when the pump shuts off and can damage piping and the motor.

Swimming pool check valves

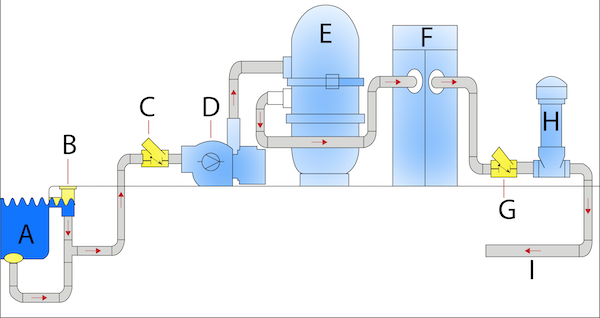

Swimming pool pumps circulate and treat pool water to keep the water sanitary. A pump draws water from the pool and passes it through a filter, a water heater (if one is installed), and an auto-chlorinator (Figure 2).

A check valve for the pool pump stops water from flowing back into the pool and keeps the pump primed. A check valve before the auto-chlorinator prevents highly chlorinated water from flowing back into the plumbing and damaging components. The pool water sufficiently dilutes the highly chlorinated water when it returns to the pool. Swimming pool check valves are commonly made of PVC and work well with chlorinated water. Learn more about swimming pool valves.

Figure 2: An example of a swimming pool plumbing system with the following components: Pool (A), skimmer (B), check valve (C), pump (D), filter (E), heater (F), check valve (G), auto-chlorinator (H), and return to the pool (I).

Check valves in a recirculation system

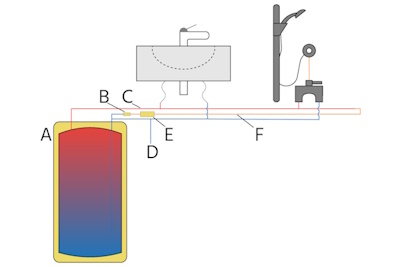

A hot water recirculation system provides hot water to a fixture. The system does this by heating water in a heater and then running the water to all hot water fixtures. The alternative would be to turn on the hot water at a fixture and then wait for it to heat up before it arrives.

Hot water recirculation check valves prevent backflow in the system:

- First, a check valve at the cold water supply to the heater prevents hot water, which has higher pressure, from flowing into the cold water supply.

- Another check valve at the heater's discharge point also prevents downstream water, which is potentially contaminated, from flowing back into the main water supply.

- Finally, a hot water recirculation system may be composed of multiple zones, especially in the case of multi-unit residential or commercial buildings.

There should be a check valve at each point that a zone connects to the main piping of the system. This check valve and a flow control valve will control the amount of water going into the zone and prevent contaminated water from returning to the main piping.

Spring-loaded check valves are typically used in a hot water recirculation system for their compact design and longevity. They are commonly made of brass or stainless steel.

Figure 3: Hot water recirculation system example: storage water heater (A), check valve to prevent backflow (B), insulated supply pipe for heat retention (C), cold water supply line (D), recirculation circulator for continuous flow (E), and insulated return pipe to maintain temperature (F).

Check valve types

Depending on the application, different types (swing, spring-loaded, diaphragm) offer various advantages.

- Swing check valves are typically used in recirculation systems due to their low-pressure drop and suitability for larger pipe sizes.

- Check valves in well water systems are often installed vertically, so a spring-loaded check valve is ideal.

- Ball check valves are particularly suitable for wastewater applications, where maintaining a clean flow is essential.

Table 1: Comparison of different check valves

| Feature/Criteria | Lift check valves | Swing check valves | Spring-loaded check valves | Ball check valves | Y-shape check valves | Sanitary check valves |

|---|---|---|---|---|---|---|

| Operation | Disc lifted by fluid flow, closes by gravity or back pressure | Hinged disc swings open with flow, closes when flow reverses | Spring mechanism compresses to open, expands to close | Ball moves away from seat to allow flow, returns to seat to block reverse flow | Y-shaped body with disc | Designed for hygienic applications, often with a spring-loaded disc |

| Advantages | Good sealing for high-pressure applications | Low pressure drop Suitable for fluids with suspended solids | Fast response to flow changes Can be installed in any orientation | Simple design, reliable operation Can handle viscous fluids | Compact design Low pressure drop | Easy to clean Suitable for food and pharmaceutical industries |

| Limitations | Lift check valve pressure drop is higher due to disc lifting Limited to horizontal installation Sensitive to debris, which can obstruct disc movement | Generally limited to horizontal installation Slower response, allowing potential backflow before sealing | Higher cost due to spring mechanism Potential for spring wear in high-cycling applications | May not seal well with low back pressure Limited to certain orientations | Not suitable for high-pressure applications Limited to specific flow conditions | Higher cost Requires regular maintenance to ensure hygiene |

| Ideal applications | Clean fluid systems with consistent flow | Water and wastewater systems with large volumes and suspended solids | Systems requiring quick response and versatile installation | Pumping systems, wastewater applications | Low-pressure steam and gas systems | Food, beverage, and pharmaceutical processing |

| Installation flexibility | Limited (horizontal only) | Limited (primarily horizontal) | High (any orientation) | Moderate (depends on design) | Moderate (depends on design) | High (often designed for easy disassembly) |

| Cost | Moderate | Low | Higher | Low to moderate | Moderate | Higher |

| Maintenance | Low to moderate, depending on debris exposure | Low | Moderate to high, due to potential spring wear | Low | Low to moderate | Moderate to high, due to hygiene requirements |

Selection criteria

Always choose the right check valve type (swing, spring, or ball) for the particular application. Also, the check valve material should be compatible with the fluid and environmental conditions to prevent corrosion and ensure durability. The other parameters to consider are:

-

Connection size: The connection size of a check valve must match the piping system to ensure a proper fit and prevent leaks.

- Typically, residential well systems use 1-inch to 2-inch (21 to 51 mm) piping. Standard garden hose connections are usually 3/4 inch (19 mm).

-

Connection types:

- Compression ring: Ideal for quick and easy installations without specialized tools, suitable for smaller diameter pipes.

- Flanged: Best for larger diameter pipes and systems requiring frequent disassembly, providing a robust connection.

- Threaded (BSP, NPT): Common for well water systems; choose based on regional standards (NPT in North America, BSP elsewhere).

- Push-in: Allows for quick installation and is ideal for applications requiring frequent connection and disconnection.

- Cutting ring: Provides a secure, leak-proof connection suitable for high-pressure applications.

-

Flow rate: The check valve's flow rate capacity should match or slightly exceed the system's flow requirements to prevent pressure drops and ensure efficient operation.

- For example, the pump's capacity in swimming pools determines the flow rate, so choosing a check valve that can accommodate the pump's maximum flow rate is essential.

-

Pressure rating: The pressure rating of a check valve must withstand the system's maximum operating pressure to prevent failure. Choose a check valve with a pressure rating that exceeds the maximum system pressure.

- Well water systems experience pressures up to 7 bar (100 psi). For swimming pools, ensure the valve can handle the pressure from the pump and any potential pressure spikes.

-

Temperature: A check valve's temperature rating should accommodate the system's operating temperature range to prevent material degradation.

- For example, hot water recirculation systems can reach temperatures up to 60 𐩑C (140 𐩑F) or higher. Choose a check valve with a high temperature rating.

FAQs

What is a water check valve?

A water check valve is necessary to prevent backflow, protect water quality, and avoid damaging plumbing systems and equipment.

Do I need a check valve on my irrigation system pump?

A check valve is recommended for your irrigation pump to prevent backflow. This can protect the pump from damage and maintain system efficiency.

How to use a check valve for a water pump?

Install a check valve on the discharge side of the pump, ensuring the arrow points in the flow direction. Secure it with proper fittings to prevent backflow and protect the pump. Test for leaks.

How do I know if a pool check valve is bad?

A pool check valve may be harmful if you notice water flowing backward, hear unusual noises, see air bubbles in the pump basket, or experience inconsistent water flow.

What is a one-way valve for a garden hose?

A check valve on the garden hose or an integrated check valve on the faucet ensures that water from the hose does not return to the main water supply, thereby protecting it from contamination.