Sump Pump Check Valve

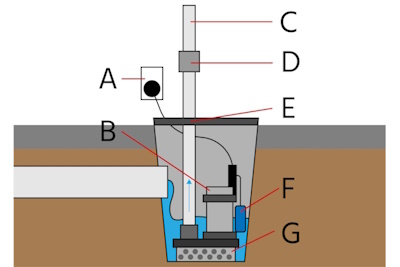

Figure 1: A sump basin with a sump pump, discharge pipe, and other components like a float switch and foot valve

Sump pump check valves prevent water from backflowing into the sump basin after the pump has shut off. They help maintain the pump's efficiency and longevity while reducing the risk of water damage. Understanding the correct placement and type of check valve in a sump basin is crucial. This article explores the kinds of sump pump check valves and their installation and maintenance practices.

Table of contents

- What is a sump pump check valve

- Signs you need a sump pump check valve

- Types of check valves for sump pumps

- How to install a sump pump check valve

- Sump pump check valve selection criteria

- Sump pump check valve maintenance

- FAQs

View our online selection of check valves!

What is a sump pump check valve

A check valve allows water to flow in one direction (out of the sump basin) while preventing it from flowing back in. When the sump pump activates, it pushes water up through the discharge pipe. Once the pump shuts off, gravity can cause the water remaining in the pipe to flow back down into the basin. The check valve stops this backflow, ensuring that the water does not return to the sump basin. The various functionalities of a sump pump check valve are:

- Pumping efficiency and protection: The check valve ensures that the sump pump does not have to re-pump the same water. This is crucial because, without the valve, the pump would cycle more frequently, leading to continuous operation and increased wear.

- Prevention from flooding: In smaller sump basins, water flowing back from the discharge pipe could be significant enough to cause overflow. The check valve stops this backflow, helping prevent flooding and water damage in the basement.

Signs you need a sump pump check valve

If you notice any of the following issues, it may be time to install a check valve:

- The pump cycles frequently, more than 10 times per hour.

- The pit refills quickly after the pump shuts off.

- You need to run the pump manually to lower the water level effectively.

- There is high humidity in the basement after heavy rain.

- There are signs of flooding in the basement.

Types of check valves for sump pumps

Spring-loaded or swing-type check valves are commonly used with sump pumps.

- A spring-loaded check valve is typically used in sump pumps to improve sealing and reduce water hammer. When fluid pressure exceeds the spring's cracking pressure, the disc opens, allowing water to flow through the valve. As the water flow slows and the pump shuts off, the spring ensures the disc returns to a closed position, preventing backflow.

- A ball check valve uses a ball, either free-floating or spring-loaded, to ensure a secure seal, maintaining pump efficiency and reducing unnecessary cycling.

- A swing check valve features a hinged disc that swings open with water flow and closes when the flow stops. This prevents water from returning to the sump pit. However, swing check valves might not seal effectively in vertical installations, which could lead to issues such as water hammer.

Table 1: Comparison of different sump pump check valves

| Feature/Criteria | Swing check valves | Spring-loaded check valves | Ball check valves |

|---|---|---|---|

| Operation | Hinged disc swings open with flow, closes when flow reverses | Spring mechanism compresses to open, expands to close | Ball moves away from seat to allow flow, returns to seat to block reverse flow |

| Advantages | Low pressure drop Suitable for fluids with suspended solids | Fast response to flow changes Can be installed in any orientation | Simple design, reliable operation Can handle viscous fluids |

| Limitations | Generally limited to horizontal installation Slower response, allowing potential backflow before sealing | Higher cost due to spring mechanism Potential for spring wear in high-cycling applications | May not seal well with low back pressure Limited to certain orientations |

| Ideal applications | Water and wastewater systems with large volumes and suspended solids | Systems requiring quick response and versatile installation | Pumping systems, wastewater applications |

| Installation flexibility | Limited (primarily horizontal) | High (any orientation) | Moderate (depends on design) |

| Cost | Low | Higher | Low to moderate |

| Maintenance | Low | Moderate to high, due to potential spring wear | Low |

Figure 2: Spring-assisted brass check valve for sump pumps

How to install a sump pump check valve

Figure 3: Sump pump check valve vertical installation: electric power (A), sump pump motor (B), discharge pipe (C), check valve (D), sump basin cover (E), float switch (F), and screen (G).

Sump pump check valves can be installed horizontally or vertically in the discharge pipe. For vertical installation:

- Position the valve between 8 inches (20 cm) above the pump's discharge and 12 inches (31 cm) above floor level. Installing the check valve above floor level makes it easy to inspect, service, or replace.

- If the valve is installed inside the sump basin, position it approximately 6 inches (15 cm) above the pump discharge. This allows drilling air release or weep holes, which help prevent air lock in pumps without a built-in prevention system. Installing the valve inside the basin can also reduce noise from water hammer, though it may make maintenance less convenient.

- Place the valve below the elbow joint where the vertical pipe transitions to a horizontal direction towards the discharge area.

When pumping out solids or semi-solids, installing the check valve horizontally (or at an angle up to 45 degrees) helps prevent debris from settling and accumulating in the valve.

Use appropriate fittings and clamps to ensure a watertight seal. To prevent backflow, ensure that the valve's flow direction arrow points away from the pump. Always refer to the sump pump manufacturer's installation instructions for specific guidance. Read our check valve installation article for more details on installing a check valve.

Figure 4: Discharge pipe connected to the sump pump

Sump pump check valve selection criteria

Use the following pointers as a guide while choosing a check valve for the sump pump:

Discharge size

Measure the drain lines and check the sump pump manufacturer's sheet to determine the right size for the discharge line. If the wrong size is chosen, the check valve may not fit correctly on the line.

Using the manufacturer's sheet

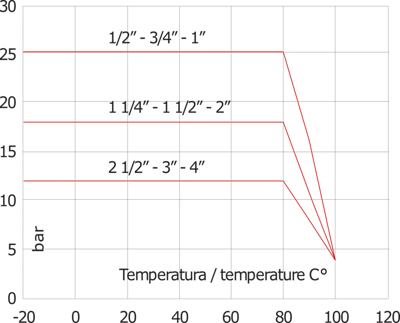

Figure 5: An example of pressure-temperature dependence for various valve sizes for brass check valves: smaller valves (up to 1") can handle higher pressures (up to 25 bar), medium-sized valves (up to 2") can hold up to 18 bar, larger valves (up to 4") can only hold up to 12 bar.

Manufacturers provide graphs that help select particular valve sizes for operating conditions like pressure, temperature, and flow rates. For example, Figure 5 illustrates the pressure limits the check valve can safely withstand, depending on the valve's size and temperature. This ensures that the valves are operated safely by verifying that the system's pressure and temperature remain within these specified limits. As seen in the temperature-pressure curve, when temperatures exceed 80 °C, it is necessary to reduce the pressure for safety. When the temperature reaches 100 °C, all valves should operate at significantly lower pressures, around 4 bar.

Materials

Sump pump check valves should be compatible with water and able to withstand heavy loads and high water pressure; therefore, choosing a durable material is crucial.

-

Metal: Metals like brass or stainless steel have high temperature and pressure tolerance and are durable and strong. However, they are costly and prone to corrosion.

- Stainless steel check valves can withstand a maximum pressure and temperature of up to 400 bar (5800 psi) and 200 𐩑C (392 𐩑F). Brass check valves can withstand up to 25 bar (363 psi) and 180 𐩑C (356 𐩑F).

- Plastic: Plastic check valves are lightweight and suitable for standard residential pressures (up to 16 bar). They are more cost-effective and corrosion-resistant to water and chemicals but not ideal for hot water above 60 𐩑C (140 𐩑F).

Read our chemical resistance guide for more details on the compatibility of different materials with various media.

Water pressure and head height

The head height is the maximum height at which a pump can move fluid against gravity. When choosing a sump pump check valve, consider the head height and the water pressure. If the pump has high driving power, the check valve may leak.

For example, consider installing a sump pump in a basement. The discharge line runs vertically up to 10 feet (305 cm) above the pump before exiting the building. In this case, the head height is 10 feet. If the sump pump is rated to handle a maximum head height of 15 feet (457 cm), it can effectively move water up to 10 feet without overexerting itself.

Connection style

Check valves are attached to the sump pump via threaded (BSP, NPT), flanged, or compression rings. Ensure the check valve’s connecting ends match the sump pump’s ends.

Sump pump check valve maintenance

A sump pump keeps the basement dry and the foundation intact. Therefore, it's essential to maintain the pump and check the valve to ensure everything is in order. Sump pump check valve maintenance requires proper installation, testing, repair, and replacement.

Inspecting and cleaning the sump pump check valve

Sump pump check valve failure

Check for water flowing back into the sump pump and the basin once the pump turns off. This signals a faulty check valve at the sump pump outlet. Perform the following steps to fix a defective sump pump check valve:

- Check for leaks or moisture on seals, connections, and the check valve.

- Fill half of the sump basin with water and check if it drains.

- Check for water backlash into the basement during testing and rainstorms.

Shifted sump pump

Seismic activities or unstable ground can cause a sump pump to shift from its intended location. If the sump pump moves, the check valve may no longer be appropriately aligned, and the pump may never know when to shut down.

Debris blocking discharge

Debris can block the water flow in a sump pump check valve. If the blockage is severe, it must be cleaned by hand. After removing the blockage, ensure the water flows out of the discharge pipe.

FAQs

What does a sump pump check valve do?

A sump pump check valve is a non-return valve that helps ensure the water pumped out doesn't flow back into the sump basin, keeping the basement and floor dry.

What happens when a sump pump check valve fails?

A sump pump check valve prevents water in the discharge pipe from flowing back into the sump basin after the pump shuts off. Without it, backflow can flood the basement or prematurely wear the pump.

Where is a sump pump check valve located?

The best location to install a sump pump check valve is at the sump pump outlet, closest to the ground level.

Can a sump pump check valve be installed horizontally?

Yes, a sump pump check valve can be installed horizontally, but it must be designed for horizontal use.