Pneumatic Cylinder Stroke Length

Figure 1: Pneumatic cylinder

Pneumatic cylinder stroke length is the maximum distance that a pneumatic cylinder can move its load. The stroke length impacts the performance and efficiency of a pneumatic system and must be carefully considered during the design and selection process. This article discusses the significance of stroke length in a pneumatic cylinder, its calculation, and its types.

Table of contents

- What is the stroke length of a pneumatic cylinder

- How to measure pneumatic cylinder stroke length

- Long-stroke and short-stroke pneumatic cylinders

- Stroke length of single-acting and double-acting pneumatic cylinders

- How to control the stroke length of pneumatic cylinder

- FAQs

View our online selection of pneumatic cylinders

What is the stroke length of a pneumatic cylinder

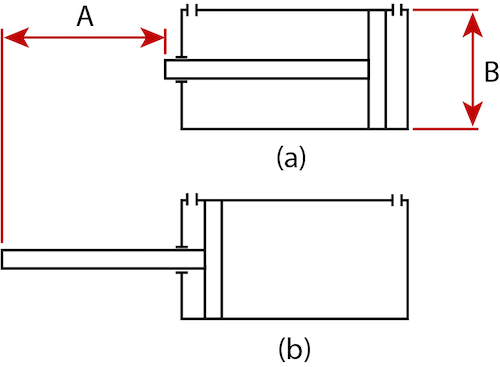

The stroke length of a pneumatic cylinder (Figure 2 labeled 'A') refers to the distance that the piston travels inside the cylinder when it is actuated by compressed air; it is the maximum distance that the cylinder can move its load. The stroke length is a critical parameter as it determines the maximum travel distance of the cylinder's piston.

- A long-stroke cylinder can move the load over a larger distance, while a short-stroke cylinder can move the load over a shorter distance.

- A cylinder with too short of a stroke length will not be able to move the load to the desired position. A cylinder with too long of a stroke length may result in overshooting the target position, in addition, a heavy a heavy load at the end of a fully extended piston can add stress to the piston causing bending.

Figure 2: Pneumatic cylinder in its standard position (a) and actuated position (b). 'A' represents the stroke length, and 'B' shows the piston diameter.

How to measure pneumatic cylinder stroke length

Use the following formula to calculate the stroke length of a pneumatic cylinder:

Stroke length = Fully extended piston length - Piston length when not extended

Ensure that the selected stroke length is compatible with the load and speed requirements of the application. For the same speed, a short-stroke pneumatic cylinder will complete more cycles than a long-stroke pneumatic cylinders. Other factors to consider when selecting an air cylinder include the bore size, operating pressure, and end fittings. The range of cylinder diameters is determined by the type or standard and is restricted accordingly. However, the range of strokes available is less restricted. The common values for stroke are, in mm: 5,10,15, 20, 25, 30, 35, 40, 50, 60, 80, 100, 125, 160, 200, 250, 320, etc.

Long-stroke and short-stroke pneumatic cylinders

Pneumatic cylinders can be classified into two categories based on their stroke length – long-stroke and short-stroke cylinders.

Long-stroke cylinders

- Long-stroke cylinders have a stroke length greater than the piston bore diameter, i.e., the ratio of stroke length to bore diameter is greater than 1.

- They are typically used in applications where a large distance needs to be covered, such as in lifting and lowering heavy loads or moving components along a conveyor belt.

- Long-stroke cylinders provide a high degree of accuracy and repeatability, making them ideal for applications that require precise positioning.

Guide units

- A guide unit in a pneumatic cylinder guides the movement of the cylinder piston rod.

- It usually consists of bearings or guide rods that provide support to the piston rod and prevent it from rotating or bending during operation.

- Guide units are especially important in long-stroke cylinders because the longer the piston rod extends, the more susceptible it is to bending, buckling, or twisting. These issues can lead to increased friction, reduced accuracy, and repeatability and ultimately result in premature failure of the cylinder.

Short-stroke cylinders

- Short-stroke cylinders have a stroke length less than the bore diameter, i.e., the ratio of stroke length to bore diameter is less than 1.

- A short-stroke cylinder has a shorter distance for the piston to travel inside the cylinder compared to its long-stroke counterpart. This helps the cylinder complete more cycles in the same amount of time at the same velocity.

- Short-stroke cylinders are compact and designed for use in confined spaces.

- They are typically used in applications where a small distance needs to be covered, such as clamping, pressing, and pushing applications.

The selection of the appropriate type of cylinder, whether it's a short-stroke or long-stroke cylinder, depends on the specific application's requirements, such as the force and speed needed and the available space.

Stroke length of single-acting and double-acting pneumatic cylinders

Single-acting pneumatic cylinders

Compressed air in single-acting pneumatic cylinders moves the piston in one direction. When the air source shuts off, a spring returns the piston to its original position.

The stroke length of single-acting cylinders is limited due to the space of the compressed spring. Therefore, the construction length of single-acting cylinders is longer than the actual stroke length. The stroke length of a single-acting pneumatic cylinder is determined by:

- The length of the piston stroke and

- The distance that the spring or external mechanism can extend the piston in the opposite direction.

The stroke length of a single-acting pneumatic cylinder is generally limited to a maximum of about 1 meter (39 inches).

Double-acting pneumatic cylinders

In a double-acting pneumatic cylinder, compressed air moves the piston in both directions. Compressed air is supplied to one side of the piston to move it in one direction, and then the air supply is switched to the other side of the piston to move it in the opposite direction.

The stroke length of a double-acting pneumatic cylinder is limited only by the length of the cylinder itself and the available air pressure. In practice, the stroke length of a double-acting pneumatic cylinder can be several meters long.

Read our articles on pneumatic cylinder force and speed for more information on each of these cylinder parameters.

How to control the stroke length of pneumatic cylinder

A user can control the stroke length of an adjustable stroke pneumatic cylinder. This can save time and money by reducing the need to purchase multiple cylinders with different stroke lengths.

There are several methods of adjusting the stroke length of a pneumatic cylinder.

- Use an adjustable cushioning mechanism on the cylinder's end cap. This adjusts the amount of cushioning provided at the end of the stroke, which can effectively reduce the overall stroke length.

- Modulate the duty cycle of the solenoid valve that’s controlling air flow to the cylinder. For this, use a proportional solenoid valve control where the controller monitors the stroke of the cylinder, and actuate the solenoid valve based on the feedback.

- Limit the air pressure feeding the pneumatic cylinder. This approach requires a controllable pressure regulator, or similar, to counteract the opposition force on the cylinder to maintain stroke position. This method is generally used with single-acting cylinders.

FAQs

What is the stroke length in a pneumatic cylinder?

The stroke length in a pneumatic cylinder is the distance that the piston can travel inside the cylinder. It refers to the maximum extension and retraction of the piston rod from the cylinder.

What is a short-stroke pneumatic cylinder?

A short-stroke cylinder is a type of pneumatic cylinder that has a shorter stroke length compared to its bore diameter.