HVAC Fundamentals

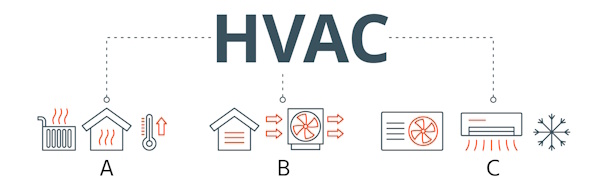

Figure 1: Heating (A), ventilation (B), and air conditioning (C)

HVAC provides thermal comfort and maintains indoor air quality in residential, commercial, and industrial buildings. The basic functions of an HVAC system are:

- Heating and cooling

- Cleaning the air

- Regulate airflow

- Pressurization

- Humidifying and dehumidifying

This article discusses the basics of an HVAC system, its working, and various types.

Table of contents

- Learning HVAC basics

- Why HVAC matters

- HVAC system working

- HVAC system types

- Where are HVAC controls required

- FAQs

View our online selection of HVAC instruments!

Learning HVAC basics

An HVAC (heating, ventilation, and air conditioning) system is designed to prevent contamination and provide comfortable living and working conditions.

- Heating maintains the appropriate room temperature, particularly in cold weather.

- Ventilation involves exchanging or replacing air within a space to regulate temperature or remove contaminants.

- Air conditioning cools indoor spaces by removing heat and humidity from the air.

Note: HVAC-R is the expanded acronym, where the 'R' stands for refrigeration. This critical component helps preserve perishable goods through precise cooling. Refrigeration is essential in industries such as food service, medical facilities, and other sectors where controlled cooling is necessary for safety and compliance.

Why HVAC matters

HVAC systems play a pivotal role in maintaining a proper indoor environment for various reasons:

- Indoor air quality (IAQ): Commercial HVAC systems are crucial in managing indoor air quality by filtering out contaminants, allergens, and particulate matter. Enhanced IAQ creates a healthier environment, mitigating the risk of respiratory conditions and allergic reactions among building occupants.

- Temperature control: Achieving and sustaining ideal temperature levels ensures comfort and productivity. HVAC systems offer precise control over temperature.

- Humidity regulation: Appropriate humidity is key to maintaining comfort and safeguarding health within indoor spaces. HVAC systems play a crucial role in controlling humidity levels, averting problems like mold generation and the discomfort that comes with excessively moist or dry air.

- Energy efficiency: Modern HVAC systems are engineered with a focus on energy efficiency, which aids businesses and homeowners in controlling operational expenses and reducing their environmental impact.

HVAC system working

Figure 2: HVAC structure: outside air (A), cooling tower (B), air handling unit comprising filter, fan, and coils (C), pump (D), chiller (E), ventilated room (F), and boiler (G).

- Outside air (A): The system takes in outside air (A), essential for ventilation. This air is drawn into the system to be filtered and conditioned before entering the indoor spaces.

- Air handling unit (C): The air handling unit (AHU) is a central component that contains the filter, fan, and coils (C). The filter cleans incoming air by removing particulates, the fan propels the air through the system, and the coils, which are connected to the chiller and boiler, condition the air by either heating or cooling it.

- Chiller (E): The chiller (E) produces chilled water. It removes heat from the water through a refrigeration cycle, which involves the evaporation and condensation of a refrigerant. The chilled water is then pumped to the AHU, which absorbs heat from the air, effectively cooling it. The chilled water loop includes an expansion tank to accommodate changes in water volume due to temperature fluctuations.

- Cooling tower (B): The cooling tower (B) is part of the cooling cycle, particularly in larger HVAC systems. It helps dissipate heat from the building by cooling water that has absorbed heat from the indoor air. The warm water from the chiller's condenser is sent to the cooling tower, which is cooled through evaporation before recirculating back to the chiller. The cooling tower is specifically associated with water-cooled chillers instead of air-cooled chillers that do not use a cooling tower.

- Boiler (G): The boiler (G) generates hot water or steam and then distributes it to the AHU's heating coils. As air passes over these coils, it is warmed before being sent through the ductwork into the indoor spaces. The boiler is typically used during colder months when heating is required. The hot water/steam from the boiler is also used for other heating applications within the building, such as radiators or in-floor heating systems.

- Pump (D): The pump (D) moves the heated or chilled water to and from the chiller and boiler to the coils in the AHU. This circulation is crucial for transferring the thermal energy needed to heat or cool the building. There are typically separate pumps for the chiller and boiler circuits. The chilled water pump circulates water between the chiller and the AHU, and the hot water pump circulates water between the boiler and the AHU.

- Ventilated room (F): The ventilated room (F) represents the indoor spaces served by the HVAC system. Conditioned air from the AHU is delivered into these rooms, providing a comfortable environment for occupants. The system also removes stale air from these spaces to maintain good air quality. The return air from these rooms is typically drawn back into the AHU to be reconditioned.

Read our HVAC instruments article for more details on the various measurement devices used in an HVAC system.

Figure 3: Ducted pipe system for ventilation and air conditioning

HVAC system types

HVAC systems are broadly categorized into self-contained unit packages and central systems, each with distinct operational methods and suitable applications.

Self-contained unit packages

Self-contained unit packages convert a primary energy source, such as electricity or gas, directly into heating and cooling for the space they serve. Examples of self-contained unit packages include:

- Rooftop HVAC systems: Often found on commercial buildings, these units are installed on the roof and provide heating and cooling to the space within the building.

- Individual room air conditioners: Portable or window-mounted units that cool single rooms.

- Air-to-air heat pumps: These systems can heat and cool by transferring heat between the air inside and outside a building.

Self-contained units are typically used in single-story buildings or individual rooms where localized control and simplicity are desired.

Central systems

Central systems convert energy from fuels like gas or electricity at a central location, then distribute thermal energy throughout the building. They consist of a central supply subsystem and various end-use subsystems, offering a wide range of configurations. The most common setup includes:

- Central hot and chilled water systems: These systems send hot and/or chilled water to multiple fan systems throughout the building.

- Fan systems with water-to-air heat exchangers (coils): These systems use the water from the central plant to heat or cool the air, then distribute it to the designated areas.

End-use subsystems in central systems can be:

- Single-zone fan systems: Serving one specific area or zone.

- Multi-zone fan systems: Utilizing VAV (variable air volume) boxes to cater to multiple zones, allowing for individual temperature control within each zone. A VAV is an HVAC system component that regulates airflow to different zones, enabling individual temperature control.

Central systems are preferred in larger, multi-story buildings with limited external air access. While they may have more complex control sequences, they generally offer lower operational costs due to their efficiency and scalability. Read our zone valve overview article for more details on the operation and features of HVAC zone valves.

Figure 4: Air conditioning (HVAC) installed on the roof of industrial buildings.

Where are HVAC controls required

HVAC controls refer to the various devices and systems used to regulate the operation of HVAC equipment in a building. HVAC control systems are essential and are strategically distributed throughout three key zones:

- Primary mechanical room controls: These controls manage the operation of the central HVAC equipment, such as chillers, boilers, and pumps. They ensure the equipment operates within the desired parameters, including safety controls, energy management controls, and interface controls for monitoring and adjusting settings.

- Air handling unit (AHU) controls: Controls for AHUs regulate airflow, humidity, temperature, and air quality. They adjust the speed of fans, the position of dampers, and the operation of heating and cooling coils, as well as humidifiers and dehumidifiers, to ensure that the air delivered to different parts of the building meets the required comfort and quality standards.

- Individual room controls: These are localized controls that manage the conditions within individual rooms or zones. They include thermostats, humidistats, and CO2 sensors that allow occupants to adjust the temperature, humidity, and air quality, as well as manage the operation of fan coil units, variable air volume (VAV) boxes, and other terminal devices that directly affect comfort in a specific area.

Figure 5: Air handling unit for the central ventilation system on the roof of a building

FAQs

What is the difference between AC and HVAC?

AC is a part of HVAC; AC regulates indoor temperature through cooling, while the HVAC system includes heating, ventilation, and air conditioning.

What is the basic principle of HVAC?

HVAC systems control indoor climate by regulating temperature, airflow, and humidity for comfort and air quality.