Solenoid Valves For HVAC-R Applications

Figure 1: Solenoid valve

Heating, ventilation, air conditioning, and refrigeration (HVAC-R) units use various devices to control the humidity, temperature, and air purity in an enclosed space, like a house. An HVAC-R system provides acceptable indoor air quality and thermal comfort within a room or building. Solenoid valves are commonly used in these systems to control the flow of refrigerants and fuels at various points throughout the HVAC-R system. This article discusses the working principle of an HVAC-R and the selection of solenoid valves for each unit within the system.

Table of contents

- What is an HVAC-R system?

- HVAC-R system working

- Solenoid valves for HVAC-R

- Functions of an HVAC-R system

- HVAC-R applications

- FAQs

View our online selection of solenoid valves!

What is an HVAC-R system?

An HVAC-R system provides a set of environmental conditions, which can be for residential or industrial purposes like a manufacturing process. Hence the system regulates room temperature, humidity, and air quality, thus providing comfortable working conditions within an industry.

- Heating: A heating system increases the room temperature during extreme cold weather conditions.

- Ventilation: Ventilation is the process of replacing or changing the air in any space to control the temperature. A natural example of ventilation is opening the window enabling airflow into the building.

- Air conditioning and refrigeration: An air conditioner is designed to cool and change the humidity within an area. Refrigeration deals with freezing and cooling an enclosed space using a coolant, and the technique is commonly used to preserve food.

HVAC-R system working process

The air handling unit (AHU) collects and combines the outdoor air with that returning from the building’s indoor area. The mixture of air is then heated or cooled, after which it is distributed into the building area through ducts.

Air conditioning and refrigeration

An air conditioning (AC) system is used for cooling and sometimes heating depending on the air properties at a given time. The cooling is done with a typical refrigeration cycle. The main parts of an air conditioning system are:

- Compressor

- Condensor

- Evaporator

- Expansion valve

The basic principle of air conditioning is to remove heat from one area, replace it with chilled air, and expel the hot, dry air into the atmosphere. A special fluid known as a refrigerant or coolant is used for this exchange of heat. The refrigerant is the actual carrier or medium of heat exchange between the external environment and the internal components. A refrigerant can change state from liquid to gaseous state and vice versa easily due to its very low boiling point. For example, the boiling point of refrigerant R410A is -480C. If this refrigerant is placed within a pipe that is kept in a room at 300C temperature, the refrigerant can easily boil and change to a vapor state. Another commonly used refrigerant is freon (R22).

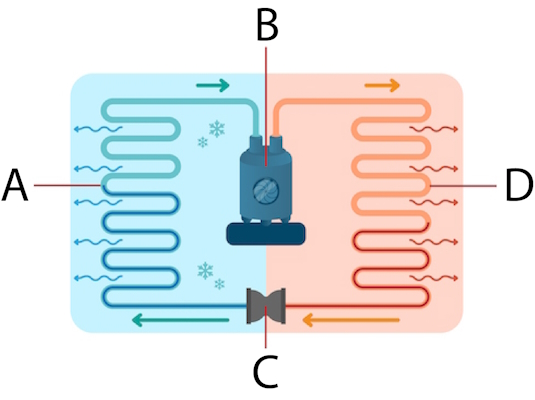

Figure 2: Air conditioning cycle: expansion valve (A), compressor (B), evaporator (C), and condensor (D).

The main steps in an air conditioning system are:

- The compressor (Figure 2 labeled B) compresses the refrigerant increasing its pressure. Increasing the pressure of a gas increases its temperature, thereby heating up the refrigerant. The refrigerant temperature is typically made higher than that of the outdoor temperature. Heat naturally flows from a region of higher temperature to a region of lower temperature. Therefore, to dispense the heat outwards, the refrigerant temperature must be higher than that of the outdoor temperature.

- The refrigerant, which is now at high temperature and pressure, passes through the connecting pipes and reaches the condenser (Figure 2 labeled D). Inside the condenser, the refrigerant changes its form from the gaseous state to the liquid state at the same temperature and pressure. The condenser coil is in the outdoor air conditioning unit and placed outside the building. The heat energy is absorbed from the hot gaseous refrigerant, and the condenser fan expels this heat into the environment, turning the refrigerant into a liquid.

- The high-temperature liquid refrigerant leaves the condenser and enters the expansion valve (Figure 2 labeled A) through a connecting pipe. The temperature of the refrigerant must be cooled down before entering the evaporator. The expansion valve decreases the refrigerant pressure, thereby reducing its temperature. The valve also controls the amount of refrigerant entering the evaporator.

- The low-pressure cooled liquid enters the copper tubes within the evaporator (Figure 2 labeled C). When the indoor air blows over the cold coils, the heat from within the room gets absorbed by the refrigerant. This causes the refrigerant to evaporate into vapor. As a result, the room environment loses heat, hence cooling down. The fan within the evaporator circulates the cold air from the coil surface for the cooling effect. The hot gaseous refrigerant is passed to the compressor, and the process repeats in a cycle.

Both air conditioners and refrigerators work on the principle of heat sinks. Both devices cool the temperature of a closed area by transferring the heat from a source (usually the closed area) to another place called a sink. The basic principle of refrigeration is similar to that of an air conditioner. Unlike an AC unit, a refrigeration system is designed to keep the cool air within the unit without blowing it away out of the unit. Also, there are no fans in the refrigerator. Refrigeration is commonly employed to cool or freeze the food at home and in various industries, whereas an AC works to cool a room or building to maintain humidity.

Heating

The process of heating is achieved by the combustion of natural gases and propane within a chamber. The main steps within a furnace heater employed in HVAC applications are the following:

- Thermostat: A thermostat is a temperature-activated switch that opens when the indoor temperature dips below a particular set point. The thermostat turns on an ignition switch by opening a valve that signals a control board to begin the heating cycle inside the furnace. After heating, when the room temperature reaches the upper setpoint, the thermostat disables the valve that closes the gas supply to the heating chamber, thus stopping the combustion process.

- Fan: Air is drawn into the burners from the surroundings, and mixed with gas (like natural gas and propane), resulting in combustion producing heat. The fan channels the heat produced in the burners into the heat exchanger, where exhaust gases are released outside the building.

- Burners: The gas is directed and burnt in a set of tubes called furnace burners. The flames are controlled by the combined operation of an igniter, gas valve, and flame sensor. When the system needs heat, the gas valves open, and the mixture is ignited using a pilot light. A pilot light is a small gas burner that lights permanently to light a larger burner whenever required.

- Heat exchanger: A heat exchanger consists of a group of tubes made of metal that is heated by the burners in order to warm the air inside. As the gas undergoes combustion inside the heat exchanger, these metal tubes get hot and radiate heat into the surrounding air. Any damage to the heat exchanger may cause combustion gases to leak into the surrounding air.

- Blower: The blower fan channels the air from return ducts into the hot heat exchanger. The air that is now in the heated state is then released throughout the building's ductwork.

- Vent: A vent collects the spent combustion gases used for generating heat and releases them outside the building. Galvanized steel is commonly used on standard units, while high-efficiency units use polypropylene venting, and these units are characterized by an easy installation procedure.

Not all industries will have HVAC systems that operate alike. Depending on the climatic conditions, the unit can have a furnace but no AC or vice versa.

Solenoid valves for HVAC-R

A solenoid valve is an electrically controlled valve with a fast response time and low power consumption that can be used effectively in multiple areas of an HVAC-R system.

Solenoid valve for AC and refrigeration units

Solenoid valves play an important role in refrigeration and air conditioning systems by controlling the flow of refrigerants. The base function of these valves is to turn the refrigerant flow on and off and thus ensure system performance. Consider the following factors while selecting a solenoid valve for AC and refrigeration units:

- Solenoid valve materials: The materials chosen for the solenoid valve must be compatible with the refrigerants like R22 (freon), R404A, R410A, and R290, to name a few. Stainless steel can be chosen for the valve body and NBR for the seal material. Read our article on the chemical resistance of materials for more information on the compatibility of various materials to different media.

- Direct-operated and servo-operated: Solenoid valves can be direct-operated or servo-operated. Servo-operated solenoid valves are generally used in larger systems. In servo-operated solenoid valves, the differential pressure must be considered along with the maximum pressure drop. The differential pressure under partial load must always be higher than the valve's minimum differential pressure for reliable operation. This minimum pressure difference is specified on the valve datasheet.

- Solenoid valve positioning: Solenoid valves are mainly positioned in the liquid line, close to the expansion valve. Placing the valves close together reduces the risk of water hammer effects.

- Normally closed/Normally open: Solenoid valves are available in two types: normally closed(valve is closed when de-energized) and normally open (valve is open when de-energized). In most cases, a normally closed solenoid valve is used if the valve is installed in the liquid line. This ensures that the valve remains closed when the system is not running and when the solenoid valve is de-energized, which eventually helps prevent refrigerant migration (the refrigerant traveling to the compressor when the device is off). Hence an electrical power disruption does not lead to any problems within the refrigeration system. In contrast, using a normally open valve can be favorable if the valve only has to be closed for brief intervals.

- Safety standards: Solenoid valves used for refrigerants must comply with several approvals from ATEX, LVD, and PED, to name a few. Read our article on CE certification for more details on the valve regulations.

Solenoid valves for heater

Solenoid valves are used to control the fuel flow to the furnace within a heater. The valve opens when the temperature drops below a particular set point to allow gas to the burner to fire it up. Once the required heating has been accomplished and the thermostat reaches the defined set point, it triggers the solenoid valve to cut off the gas to the burner. When the temperature is too cold, the valve opens the gas, and the burner starts. Solenoid valves are highly reliable when installed in harsh environments and have low maintenance levels resulting in low lifecycle costs. Consider the following factors while selecting a solenoid valve for heaters:

- Solenoid valve material selection: Furnaces typically use fuels like natural gas or propane to produce heat when burned. Natural gas and propane are compatible with brass, aluminum, cast iron, or steel for the body, and nitrile rubber for the seal material of the valve.

- Working temperature and pressure: The valve works on a wide range of pressure for the medium from very low to very high (typically 30 psi or higher). If the application sees extreme temperatures of valve operation, make sure to rate the valve accordingly. Very low ambient temperatures (like 400C) require specialized elastomers for leak-free sealing.

- Explosion-proof certifications: As the fuel media used in the solenoid valve is highly combustible, sufficient care must be taken to prevent any spark from originating within the coil or housing. The valve’s coil or enclosure must be explicitly specified to suppress any explosion originating from the valve. There are several standards for classifying devices for a hazardous environment like NEMA (National Electrical Equipment Manufacturers Association (USA)), ATEX (ATmosphères EXplosibles (EU)), and IEC Ex (International Electrotechnical Commission Explosive (global)). While purchasing a valve for working with explosive fuels, make sure to check the marks of one of these standards on the valve.

- IP rating: Ensure the valve has the appropriate IP rating for protection from dust, liquid, moisture, and contact. This is particularly important when the valve is installed in harsh industrial environments for remote operation. Read our article on fuel, oil, gas, & propane solenoid valves for more information about the design features and selection criteria of solenoid valves for fuels.

Functions of an HVAC-R system

- Heating and cooling

- Humidifying and dehumidifying

- Cleaning the air

- Regulating airflow

Figure 3: Air conditioning system

HVAC-R applications

HVAC-R systems are commonly used in:

- healthcare facilities

- laboratories

- hotels

- nuclear facilities

- health-care facilities

- residential apartments

- commercial and public buildings

FAQs

What does HVAC-R mean?

HVAC-R system refers to the mechanical systems used in heating, ventilation, air conditioning, and refrigeration within an industry or building.

Which chemical is used in an air conditioner?

An air conditioner uses a refrigerant such as freon.

What is the difference between air conditioning and refrigeration?

The refrigeration process keeps the cold air confined within a space, whereas an air conditioner pushes it away. Refrigeration uses a coolant alone to cool an area, but an air conditioner uses the air from outside.

Can air conditioners be used as heaters?

A few ACs that come with a fitted heat pump can be used as a heater too. When the heat mode is turned on, the device produces warm air.

What is a solenoid valve used for?

A solenoid valve is commonly used to shut off, release, distribute, dose, or mix various fluids.