Miniature Circuit Breaker

Figure 1: A row of miniature circuit breakers mount on an electrical switchboard.

An MCB (miniature circuit breaker) protects electrical circuits from overcurrents, such as short circuits and overloads. It automatically interrupts the flow of electrical current when the current exceeds a certain level, preventing damage to the circuit and potential fire hazards. MCBs are smaller in size compared to traditional circuit breakers, making them ideal for use in tight spaces. This article discusses the construction, working principle, and applications of MCBs. Read our article on circuit breakers to understand more about their basic working and types.

Table of contents

- Construction

- How does a miniature circuit breaker work

- Miniature circuit breaker types

- Advantages

- Applications

- FAQ

View our online selection of circuit breakers!

Construction

An MCB consists of the following components:

- Main contacts: The main contacts carry the load current. They are connected to the incoming and outgoing wires of the circuit.

- Trip unit: The trip unit checks the current flow through circuit and trips the circuit breaker in the event of an overcurrent or short circuit. It is composed of current-sensing elements like a bimetal strip or magnetic actuator.

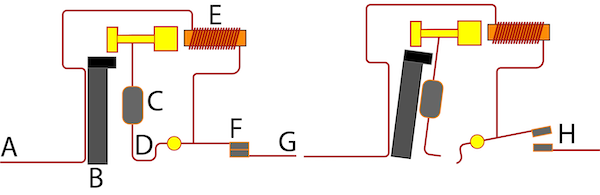

- Terminals: The outgoing (Figure 2 labeled A) and incoming (Figure 2 labeled G) wires are connected to the terminals on the circuit breaker.

- Housing: The housing protects and holds the MCB's parts. It also offers insulation between the electrical elements and live parts.

- Trip indicator: The trip indicator in an MCB is a visual cue that displays whether the circuit breaker is in the 'ON' or 'OFF' state.

- Auxiliary contacts: Auxiliary contacts are the additional contacts available on certain MCBs to switch auxiliary loads or provide signaling functions.

- Trip spring: The trip spring (Figure 2 labeled C) is a spring device that keeps the MCB contacts in the 'on' or closed position. The trip spring is released when the trip unit is activated, causing the contacts to separate and break the circuit.

How does a miniature circuit breaker work

Figure 2: Miniature circuit breaker working principle in the closed (left) and open (right) positions: load (A), bimetallic element (B), trip bar (C), latch (D), magnetic element (E), closed contacts (F), line (G), and open contacts (H).

The trip unit is the essential part responsible for the proper functioning of the MCB. In a hybrid MCB, there are two trip mechanisms: a bi-metal that protects against overload current and an electromagnet that protects against electric short circuit current. There are also other MCB types that include only either one of these tripping mechanisms, as discussed in the next section.

- Thermal element: The thermal element of an MCB is a bimetallic strip (Figure 2 labeled B) that heats up when current flows through it. As the current increases, the bimetallic strip bends due to the heat and eventually trips the MCB when it reaches a certain temperature. The thermal mechanism in a hybrid MCB is calibrated to trip at a specific temperature. The set temperature is typically determined based on the expected load and operating conditions of the circuit. For example, MCBs used in residential applications typically have a lower set temperature compared to those used in industrial or commercial applications due to their lower current requirements.

- Magnetic element: The magnetic element of an MCB (Figure 2 labeled E) is a solenoid coil that creates a magnetic field when current flows through it. The magnetic mechanism is calibrated to trip at a specific current level. The magnetic field pulls on a spring-loaded trip lever that releases the switch, tripping the MCB. This mechanism protects against short circuits, which occur when the current flows through a low-resistance path, such as a damaged wire.

Normal operation

During normal operation, current flows through the MCB and into the electrical circuit. The MCB has two contact points, one connected to the incoming power supply and the other to the load. The current flows from the incoming contact through the MCB's internal conductor and into the load.

Overload and short circuit

Overload

If the current flowing through the MCB exceeds its rated current due to an overload, the bimetallic strip in the MCB's internal trip mechanism will heat up and bend. This bending causes the trip mechanism to move, which triggers the MCB to open its contacts and interrupt the current flow (Figure 2 labeled H). The MCB will remain in the tripped position until it is manually reset.

Short circuit

In the case of a short circuit, a sudden surge of current flows through the MCB, causing the magnetic element to generate a magnetic field. This magnetic field attracts the trip mechanism, which will cause the MCB to open its contacts and interrupt the current flow. The MCB will remain in the tripped position until it is manually reset.

Resetting the MCB

Once the MCB has tripped, it can be reset manually by toggling the switch to its original position. This allows the MCB to restore power to the electrical circuit if the fault has been resolved. However, if the fault is still present, the MCB will trip again and interrupt the current flow.

Miniature circuit breaker types

Working mechanism

MCBs come in different types based on various factors such as current rating, voltage rating, and trip characteristics. Some commonly used types include:

- Thermal MCBs: Thermal MCBs trip when the temperature rise caused by the current flowing through the circuit exceeds a certain threshold. They have a bimetallic strip that bends and trips the breaker.

- Magnetic MCBs: Magnetic MCBs trip when the magnetic force generated by the current flowing through the circuit exceeds a certain threshold. They have a solenoid that pulls the trip spring and trips the breaker.

-

Hybrid MCBs: Hybrid MCBs combine the features of both thermal and magnetic MCBs. They have a bimetallic strip and a solenoid and trip based on either the temperature rise or the magnetic force generated by the current.

- Hybrid MCBs have the features of both thermal and magnetic tripping mechanisms, which allows them to respond faster to both overloads and short circuits. This faster response time means the hybrid MCB will trip more quickly than a thermal-type or magnetic MCB, reducing the risk of equipment or electrical systems damage.

- Electronic MCBs: These MCBs use electronic components to monitor the current and trip the breaker. They are more sensitive and provide faster and more accurate tripping than thermal and magnetic MCBs.

- Differential MCBs: Differential MCBs are used in DC circuits and protect against earth faults and short circuits. They monitor the current flowing in the live and neutral wires and trip the breaker when the difference exceeds a certain threshold.

- Residual Current Circuit Breaker (RCCB):Residual current circuit breakers protect against electric shock and fire caused by earth faults. They monitor the current flowing in the live and neutral wires and trip the breaker when the difference exceeds a certain threshold.

- Isolation MCBs: Isolation MCBs are used as switches to isolate a circuit. They do not have a trip mechanism and are used to switch the circuit off for maintenance or testing purposes.

Tripping currents

MCBs can be classified according to their instantaneous tripping currents. They protect the circuit typically within one-tenth of a second.

Type A MCB

A Type A MCB is designed to trip the circuit when the current exceeds 2-3 times its rated current. It is particularly sensitive to short circuits, making it suitable for semiconductor manufacturing.

Type B MCB

Type B is designed to quickly disconnect electrical circuits if the current exceeds three to five times its rated limit. It's typically used for smaller loads with minimal switching surges, such as residential or light commercial applications.

Type C MCB

Type C MCB is designed to immediately switch off the electrical circuit if the current exceeds five to ten times its rated capacity. Typically, this MCB is utilized for devices with high inductive loads, such as small electric motors and fluorescent lighting, which experience switching surges. Type C MCBs are generally preferred for applications requiring higher short circuit currents. As a result, these MCBs are suitable for use in commercial and industrial installations with high inductive loads.

Type D MCB

Type D is designed to trip instantly when the current passing through it exceeds its rated capacity by ten to twenty-five times. They are typically utilized for high inductive loads where the frequent high inrush current surges are expected.

These circuit breakers are specifically designed for use in industrial and commercial settings. Examples of such applications include x-ray machines, uninterruptible power supply systems, industrial welding equipment, and large motors with winding.

Type K MCB

The K miniature circuit breaker (MCB) can tolerate a current flow of 8 to 12 times its rated capacity. It is commonly used in heavy-duty load devices such as compressors, winding motors, and X-ray machines.

Table 1 summarizes the minimum and maximum trip currents of various MCB types. 'Ir' is the rated current of the MCB; it is the maximum amount of electrical current that the MCB is designed to carry continuously without tripping. Miniature Circuit Breakers can also be categorized according to their number of poles, including single-pole, double-pole, triple-pole, and four-pole MCBs.

Table 1: Minimum and maximum trip currents of various MCB types.

| MCB Type | Minimum trip current | Maximum trip current |

| Type A | 2 Ir | 3 Ir |

| Type B | 3 Ir | 5 Ir |

| Type C | 5 Ir | 10 Ir |

| Type D | 10 Ir | 20 Ir |

| Type K | 8 Ir | 12 Ir |

Advantages

- Compact size: Installing miniature circuit breakers in confined spaces is easy, given their small size. They are also lightweight, making them ideal for applications where weight is a concern. Their modular design allows for easy replacement of individual units without affecting the rest of the system.

- Fast action: MCBs are designed to trip quickly and interrupt the current flow within a few milliseconds when a fault is detected, thus protecting the circuit and connected appliances from damage.

- High sensitivity: MCBs can detect even minor overloads and short circuits, making them an effective protection device for electrical systems.

Applications

MCBs (Miniature Circuit Breakers) and traditional circuit breakers both function as protective devices that automatically interrupt the electrical current flow in a circuit when it exceeds the safe operating limit. However, MCBs have some distinctive features and are utilized in different applications compared to traditional circuit breakers.

Some typical applications of MCBs include:

- Residential and commercial buildings: MCBs are frequently used as a primary protective device in low-voltage electrical installations in homes, offices, and other buildings. They are often integrated into consumer units, distribution boards, or switchboards to provide protection against overcurrent, short-circuit, and overload conditions.

- Industrial applications: MCBs are also used in industrial settings for the electrical protection of various equipment such as motors, pumps, and other types of machinery. They are used in conjunction with other protective devices, such as contactors, relays, and fuses, to provide a comprehensive protection system.

- Automotive applications: MCBs are often used in automotive applications to protect against overcurrent and short-circuit conditions. They are typically found in vehicles' electrical distribution systems, protecting various components such as lights, wipers, and motors.

In contrast, traditional circuit breakers are generally larger and used for higher current ratings and voltage levels, typically found in high-power industrial applications such as factories, power plants, and heavy machinery. They are also used in power distribution systems, such as the main breaker panel or switchgear, to protect against overcurrent, short-circuit, and ground-fault conditions.

Read our articles on smart circuit breakers and earth leakage circuit breakers for more details on the features of various circuit breaker types.

FAQ

What are the advantages of miniature circuit breakers?

Miniature circuit breakers have a fast response time, low replacement cost, provide improved safety, and they are easy to reset.