How Does Temperature Affect Pneumatic System Performance?

Figure 1: Industrial pneumatic system with pressure gauge

The temperature of the compressed air can negatively affect the performance of pneumatic systems. It can change air density, pressure, and the properties of system components. Understanding this relationship is important for maximizing efficiency and preventing problems. This article discusses how temperature variations impact pneumatic systems and provides solutions to minimize their effects.

Table of contents

- Optimal operating temperature

- Effects of warmer conditions on pneumatic systems

- Other tips to manage excess heat

- Effects of colder conditions on pneumatic systems

- Managing air compressor in cold weather

- FAQs

View our online selection of FRLs and pneumatic mufflers!

Optimal operating temperature

The right temperature for compressed air systems is crucial for their efficient operation. Ideally, the ambient temperature should be between 10 and 29 𐩑C (50 to 85 𐩑F). Staying within this range helps to control compressor heat and minimize humidity problems. Good ventilation and air conditioning can help maintain this temperature so that the system lasts longer and operates reliably.

Effects of warmer conditions on pneumatic systems

During the summer, rising temperatures and increased humidity can put extra stress on the compressed air system. This can significantly reduce its efficiency.

Higher air inlet temperatures

A compressor mounted on a combustion engine or housed in an enclosure makes the ambient air hotter than the outside air, reducing its efficiency.

- Compressors intake air and compress it by decreasing its volume. When the air temperature increases, its density decreases and it takes up more space. Since compressors have a limited volume, the amount of compressed air decreases at higher temperatures. This means the compressor needs more strokes to reach the desired pressure.

- Colder air is denser, allowing more air mass to be compressed in each cycle. This increases efficiency and performance.

For example, using air at 20 𐩑C (68 𐩑F) instead of 80 𐩑C (176 𐩑F) increases output by 20.4% due to the higher density of cooler air. This means the compressor can draw in and compress 20.4% more air mass, resulting in improved performance.

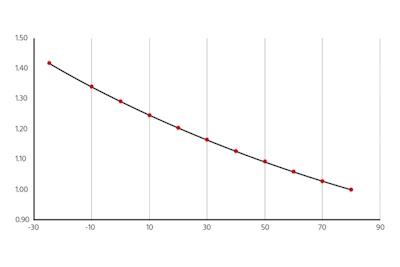

Figure 2: Air density at ambient temperatures

Symptoms

- Frequent shutdowns, especially in hot weather

- Overheating warnings or alarms from the system

- Reduced efficiency or performance of the pneumatic system

- Noticeable increase in the temperature of the compressor housing or components

Solutions

- Extend the intake tube to draw cooler air, which can potentially improve performance by 10-20%, and optimize hose sizing while maintaining the intake filter to enhance efficiency.

- Position the intake pipe in a location free from contaminants like rain and dirt, ensuring the pipe size is adequate to prevent pressure drop if drawing air from a remote location.

Lubrication and component damage

When air is compressed, its temperature rises. If the outside air is also hot, this can cause overheating. This reduces how well cooling systems and lubricants work. It can also damage machine parts.

- Excess heat can cause lubricants to thin out or turn into vapor. This increases friction and wear on parts of the system. For example, in a pneumatic cylinder, lubricants may not work well at high temperatures between the piston and cylinder wall. This leads to more resistance and wear, decreasing the cylinder's performance and lifespan.

- High temperatures can harm the seals inside the cylinder. Static seals prevent leaks when the cylinder is still. Piston seals keep pressure as the cylinder moves. Heat can make these seals hard, crack, or lose their stretch. This leads to air leaks and less efficiency.

- High heat can also cause chemical reactions between the cylinder parts and outside agents. This can further damage the seals and parts, and may cause corrosion.

- Electrical parts can be harmed too. Extreme heat can melt insulation and hurt circuits. High temperatures can cut the compressor motor's lifespan in half. It can also greatly reduce oil life. This can cause system failures and expensive repairs.

Symptoms

- Unusual noises, such as grinding or squealing, which indicate increased friction

- Frequent tripping of circuit breakers or blown fuses, suggesting electrical issues

- Noticeable decrease in compressor performance or efficiency

- Overheating warnings or shutdowns from the compressor's safety system

Solutions

- Use high-temperature oils to maintain the performance and longevity of machinery components, such as bearings and bushings, in hot environments.

- Regularly check and replace lubricants as needed to ensure optimal functioning.

Increased humidity and moisture issues

High compressed air temperatures cause water to evaporate and humidity to rise. Humidity rises when this moist air is compressed, leading to water accumulation. Temperature fluctuations, especially if the compressed air is warmer than the environment in which it is delivered, worsens this problem. The accumulation of moisture puts additional strain on the filtration and drying systems. Moisture in air ducts can cause serious problems, such as

- Corrosion: Moisture causes rust in metal tanks and ducts, which can clog systems and spread contaminants.

- Damage to components: Moisture can clog fine passages, damage seals and cause pressure fluctuations that damage cylinders and valves.

- Contamination: Moisture can introduce bacteria and contaminants that pose a health risk in food processing and affect product quality in paint applications.

- Increased costs: Moisture can lead to higher maintenance costs, downtime and reduced efficiency.

Symptoms

- Visible water or condensation in air lines and around components

- Rust or corrosion on pipes, fittings, and other metal parts

- Frequent clogging or blockages in the system

- Decreased performance or efficiency of pneumatic equipment

Solutions

- Regular draining: Drain compressors regularly, especially in warmer months, to remove the collected water.

- Temperature control: Maintain consistent temperatures and ensure good ventilation to reduce moisture buildup.

- Air drying systems: Use refrigerated or desiccant air dryers to effectively remove moisture from the system.

- Better system design: Design systems to minimize rapid temperature changes and use rust-resistant materials. Connect piping at the top to reduce moisture buildup.

Other tips to manage excess heat

- Clean and maintain air conditioners and heat exchangers regularly. This helps them work efficiently.

- Monitor both room and system temperatures. Schedule operations during cooler times to reduce heat stress.

- Use high-quality air filtration and drying systems. This removes extra moisture from the air effectively.

- Use a gauge to track pressure drop. Maintain the pressure at the right level for optimal performance.

- Regularly check and clean drainage systems. This prevents blockages and ensures proper functioning.

- Inspect the compressor air intake pipe for any contaminants. Make sure the intake filter is the right type, properly installed, and clean.

Effects of colder conditions on pneumatic systems

- Air compressors can struggle in cold weather, especially below 4 𐩑C (40 𐩑F). This can result in reduced efficiency and performance.

- Cold temperatures can freeze condensate, causing clogs or cracks in system components like control lines, drain valves, filters, and heat exchangers.

- Cold conditions can cause immediate blockages and long-term damage to system components. For example, rotary screw compressors may fail to start in low temperatures due to low ambient temperature limit switches.

- Cold temperatures can also harden rubber seals and gaskets, resulting in leaks and reduced flexibility.

Air density and pressure drops

Cold weather increases air density, which leads to a decrease in pressure within pneumatic systems if the system doesn't compensate for the lower temperature. This results in slower response times, reduced power output, and decreased efficiency of tools and machinery.

To ensure air density is suitable for a pneumatic system, first check the system's specifications for optimal operating conditions. Measure the current air density and compare this with the system's requirements; if performance issues arise, consider adjusting environmental conditions or system settings.

Increased energy consumption

Cold temperatures cause the oil in the system to thicken, reducing lubrication efficiency. This necessitates more force to operate the pump mechanism, increasing energy consumption and wear on the system. Additionally, compressors may fail to switch on if ambient temperatures fall too low, as a protective measure to prevent damage.

Corrosion risks

Lower temperatures can also lead to increased corrosion risks, as drying mechanisms become less efficient. Moisture can accumulate and remain in the system for extended periods, causing rust and blockages.

Managing air compressor in cold weather

Here are some strategies to manage cold temperatures in pneumatic systems:

- Use space heaters, heating blankets, or crankcase heaters to keep critical components above freezing temperatures and maintain compressor oil warmth.

- Install heated drains, automatic drain valves, and regularly check condensate traps to prevent freezing and blockage.

- Use low-temperature lubricants designed for cold environments to improve starting performance and system efficiency.

- Employ antifreeze solutions or additives to lower the freezing point of moisture in the system, and ensure proper drainage and drying of air to minimize moisture content.

- Regularly maintain and replace filters to ensure efficient airflow and reduce energy consumption.

- Use corrosion-resistant materials and coatings for components exposed to moisture, and implement regular maintenance schedules to inspect and clean components.

- If possible, relocate compressors and sensitive components to indoor or temperature-controlled environments, or use weatherproof enclosures for outdoor equipment to protect against cold and moisture.

FAQs

What should I do if my air compressor is hot to touch?

If your compressor feels hot, check the ventilation, make sure the cooling system is working and check for blockages or mechanical problems.

What are the most common causes of an overheated air compressor?

An air compressor can overheat due to inadequate ventilation, clogged filters, excessive ambient temperatures or mechanical problems such as worn components.

Why is my air compressor not working in cold weather?

An air compressor can stop working in cold weather due to thickened oil, frozen condensation or problems with the battery that affect starting.

What happens to the air pressure in cold weather?

Air pressure decreases in cold weather because the air molecules move closer together in cooler temperatures, lowering the overall pressure.