Burkert 6213 Solenoid Valve - How They Work

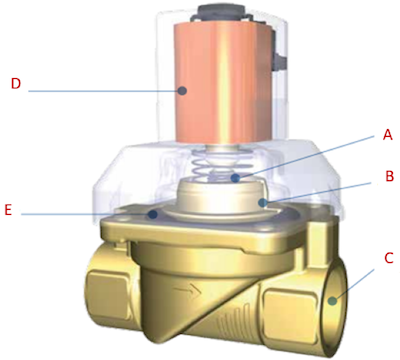

Figure 1: Burkert 6213 solenoid valve

The Burkert Type 6213 is a 2/2-way servo-assisted (semi-direct) solenoid valve from the Burkert S. EV series. It is primarily used for liquid or gaseous media with little or no differential pressure. The valve operates with the help of a spring-coupled diaphragm and a plunger pilot control, allowing it to partially open without differential pressure. The Burkert 6213 offers a variety of materials, design options, and certifications to suit different applications. It is similar to other Burkert servo-assisted valves, such as the 0290, 6281, 5282, and 0141, despite differences in their opening and closing mechanisms.

Table of contents

- Is the Burkert 6213 the right valve for you?

- Operating principle

- Approvals

- Features & special versions

- Burkert product similarities

- Applications

Buy Burkert 6213, 0290, 6281, 5282, and 0142 Online Now!

Is the Burkert 6213 the right valve for you?

This valve might be the right valve for your application if:

- Your medium is a gas or liquid (including drinking water)

- Little or no differential pressure is present (gravity fed system or closed loop circulating system)

- A nominal diameter between 12 and 40 mm is desired

- Your maximum operating pressure is below 10 bars

Operating principle

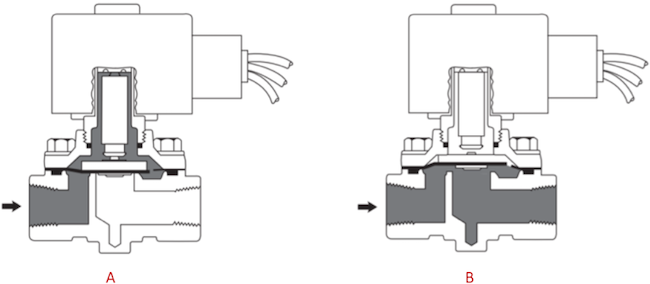

The Burkert type 6213 is a semi-direct operated solenoid valve. The valve opens and closes by moving a flexible diaphragm. The diaphragm is used as a seal, as seen in Figure 2, to separate the valve inlet and outlet. The valve has a pilot and bleed orifice that are used to regulate the pressure difference on both sides of the diaphragm. By controlling the pressure differential on both sides, the diaphragm is pushed upwards or downwards to assist the opening or closing of the valve.

Figure 2: Burkert Type 6213 components: connecting spring (A), diaphragm holder (B), body (C), coil (D), and diaphragm (E)

All versions of the valve are normally closed (NC). This means the flow is blocked when zero current is fed to the coil.

Semi-direct operated solenoid valves combine the properties of direct and indirect valves. They can handle a high flow rate and work from zero bar. They feature a moveable membrane with a small orifice and pressure chambers on both sides of the membrane. In a semi-direct valve, the plunger is directly connected to the membrane. Therefore, when the plunger is lifted it directly lifts the membrane to open the valve. At the same time, a second orifice is opened by the plunger that has a slightly larger diameter than the first orifice in the membrane. This causes the pressure in the chamber above the membrane to drop. As a result, the membrane is lifted not only by the plunger, but also by the pressure difference. Often, semi-direct operated valves have more powerful coils than indirect operated valves. Semi-direct operated valves are sometimes called assisted-lift solenoid valves. Figure 3 shows the operating principle of the Burkert 6213.

Figure 3: Type 6213 operating principle: de-energized (A) and energized (B)

Approvals

This valve series is available with a wide variety of approval. The most important ones are listed below:

- UL, UR: Inspects and certifies products according to their safety requirements.

- ATEX, IECEx: Approval of devices and protective systems used in explosion-prone areas.

- KTW, W270: Guideline which approves materials for use with potable water in Germany.

- Safety shut-off valve: Safety shut-off valve in accordance with DIN EN ISO 23553-1, which approves the device as a safety shut-off valve for oil burners in accordance with DINCERTO up to 10 bar.

- Free of oil, grease, and silicon

Features & special versions

Material selection

The available housing material with their suggested media are:

- Brass: For most used media, such as water, air or oils. Designed to meet European drinking water requirements.

- Stainless steel body: For mildly acidic and alkaline solutions and ultra-pure water or fluids that require high chemical resistance.

- Dezincification-resistant brass: For slightly acidic and alkaline water.

- Nickel-plated brass: For mildly acidic and alkaline solutions.

The available seal material with their suggested media are:

- NBR (Nitrile Rubber): Neutral fluids, water, hydraulic oil, oil without additives

- FKM (Fluorocarbon rubber): Hot oils with additives

- EPDM (Ethylene-propylene-diene rubber): Oil and fat-free fluids and gases

Port size range

The Burkert valve 6213 is available with port sizes from G ¼” to G 2”. The table below shows the corresponding orifice sizes and Kv-values. The Kv-value indicates the flow rate of water in m3 per hour with a pressure drop of 0.5 bar. Correct valve sizing is very important to guarantee good performance of your system and to optimize costs. Use our valve sizing calculator to quickly determine the right valve size.

| Port size | Orifice (mm) | Kv (m3/h) | Pressure range (bar) |

| G3/8 | 10 | 1.9 | 0 – 10 |

| G1/2 | 13 | 3.6 | 0 – 10 |

| G1/4 | 20 | 8.3 | 0 – 10 |

| G1 | 20 | 8.3 | 0 – 10 |

| G1 | 25 | 11 | 0 – 10 |

| G 1 ¼ | 25 | 11 | 0 – 10 |

| G1 ½ | 40 | 30 | 0 – 10 |

| G2 | 40 | 30 | 0 – 10 |

* The HP00 version is available for applications with no differential pressure.

ATEX

Explosion proof versions of this valve type are suitable for potentially explosive environments. The ATEX ratings are:

- II 2G Ex mb IIC T4 Gb

- II2D Ex mb IIIC T135C Db

- Ex mb IIC T4 Gb

- Ex mb IIIC T135C Db

Reduced electrical power

The Burkert 6213a can be supplied with integrated power reduction with the use of a “Kick and Drop” coil. Just after the valve opens, the electric power is reduced far enough that the valve remains open. Therefore, the Burkert solenoid valve 6213a has a reduced energy consumption and decreased coil heating compared to the normal version.

Vibration resistance and noise dampening

In the Burkert 6213 valve, the coil is screwed with bolts directly to the valve body. This tightly coupled design prevents disturbances and increases stability in applications with strong vibrations. Additionally, the diaphragm is available in various materials such as NBR, FKM and EPDM to reduce and dampen noise during valve closing.

Electrical connection

For ease of installation and interconnection between solenoid plug vendors, the Burkert 6213 conforms to DIN EN 175301-803 Form A or has a moulded connector. Burkert offers compatible cable plug accessories with the Burkert type 6213 for easy integration. Cable plug accessories are sold separately.

HP00 version

Although the integrated spring coupling will assist in opening of the valve, the standard Burkert 6213 will require a minimal differential pressure to fully open the valve. A special version “HP00” is available for applications which require valve opening with no valve pressure. This version features a stronger closing spring than the standard version and is well suited for gas or vacuum applications. The “HP00” is offered in port sizes from G 1/2“ to G 1“ and in pressure ranges from 0 to 10 bar. Similar to the standard type 6213, the “HP00” is offered in a wide range of body and seal materials.

Burkert product similarities

Burkert offers a wide range of servo-assisted valves to meet the needs of a diverse range of applications. The Burkert valves below are all servo-assisted valves and similar to the Burkert solenoid valve 6213. However, each valve type uses a different opening and closing mechanism to satisfy the needs of different applications.

Burkert 0290

Similar to the Burkert 6213 the Burkert 0290 is suitable for use in liquids and gases and offers similar material options. The Burkert 0290 uses a fixed coupling between the diaphragm valve and plunger. This design offers further reliability for switching without differential pressure. The media pressure is only necessary for complete opening of the valve.

Burkert 6281

Similar to the Burkert 6213, the Burkert 6281 is suitable for use in liquids and gases and offers similar material options. The 6281 uses a direct acting plunger valve as the pilot valve. This design requires a minimum differential pressure between the valve inlet and outlet for opening and closing.

Burkert 5282

The Burkert 5282 is a servo-assisted diaphragm valve which satisfies European drinking water requirements similar to the Burkert 6213. The Burkert 5282, however, is equipped with a 3/2-way pilot valve as opposed to the 2/2-way pilot valve used by the Burkert 6213. The 3/2-way valve operates to isolate the media and pilot assembly. This design makes the 5282 suitable for aggressive or slightly contaminated media. The Burkert 5282 also offers adjustable closing and opening times and manual override for start-up and testing. A minimum differential pressure is required for this valve to function.

Burkert 0142

The Burkert 0142 features a 3/2-way pilot valve as opposed to the 2/2-way pilot valve used by the Burkert 6213. The 3/2-way valve operates to isolate the media and pilot assembly. This design makes the Burkert 0142 suitable for aggressive or slightly contaminated media. The 0142 is offered in metal free housings with PVC or PVDF. The Burkert 0142 also includes manual override for start-up and testing. A minimum differential pressure is required for this valve to function.

Applications

Electrode cooling of welding robots: Welding robots, which use welding electrodes in continuous operation, require cooling to prevent component failure and reduce extended service life. Water-cooling through a secondary pipe can be used to prevent the electrode from burning. The Burkert 6213 duty cycle is rated for 100% continuous duty and is suitable for the continuous demands of this application.

Shut-off valves for oil supply systems: Oil fired systems supplied with fuel must comply with special safety requirements to shut off oil supply lines. The Burkert 6213 solenoid valve is in accordance with DIN EN ISO 23553-1 to satisfy valve safety shut off requirements.

Osmosis system: Untreated water used in osmosis systems contain contaminated water at the valve that feeds water into the system. The Burkert 6213 solenoid valve designed in stainless steel ensures resistance against the untreated water.