Burkert 0290 Solenoid Valve - How They Work

Figure 1: Bürkert 0290 Solenoid Valve

The Bürkert type 0290 is a general purpose, normally closed 2/2 way semi-direct operated solenoid valve. It is part of Bürkert’s S.EV (servo-assisted) valve series. This valve series features a diversity of materials and design options, which along with variety of certifications, provides for a universal solution for your application.

Bürkert type 0290 was developed for reliable switching with liquids and gases at a differential pressure of little to zero bar. The opening process in this valve is supported by the fixed coupling of the diaphragm to the plunger which allows the valve to open without differential pressure.

Table of contents

- Is Bürkert 0290 the right valve for you?

- Operating principle

- Approvals for the 0290 valve

- Features

- Applications

Explore the online selection of Bürkert 0290!

Is Bürkert 0290 the right valve for you?

This valve might be the right choice for your application if:

- your medium is a clean fluid or gas. The valve is available with brass or stainless-steel housings and sealing materials such as NBR, FKM and EPDM. The wide range of combinations makes the valve suitable for many neutral or aggressive fluids.

- little or no differential pressure is present for opening and closing

- a nominal diameter between 12 and 50 mm is desired

- your maximum operating pressure is below 16 bars

- your system experiences strong vibrations

- your medium is oxygen and you need a certified valve (BAM)

Operating principle

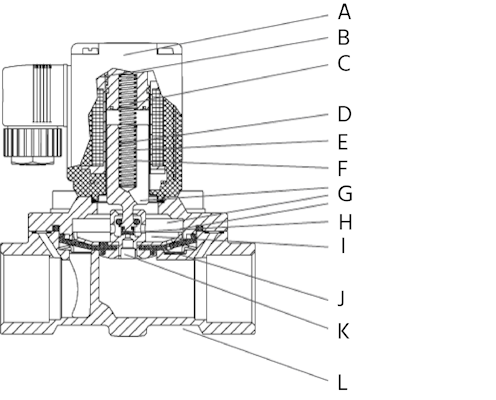

The Bürkert 0290 solenoid valve uses a pilot valve to indirectly open and close a diaphragm. The diaphragm holder of the main valve is connected to the plunger rigidly. This allows the pilot valve to partially open the main valve without differential pressure. When the pilot valve is energised, a small port opens and allows the media from the upper chamber to flow out. The media pressure raises the diaphragm and completely opens the main valve. When the pilot valve is de-energised, a compression spring brings the diaphragm down, media flows to the upper chamber through a small opening and the built-up pressure creates a reliable seal (figure 2).

Figure 2: Functioning Principle of Type 0290 with components coil (A), stopper (B), shading ring (C), spring (D), magnetic core (E), guide (F), O-rings (G), seat seal (H), diaphragm support disc (I), diaphragm (J), pilot seat and nipple (K), and body (L).

Approvals for the 0290 valve

This valve type is available with the below listed approvals:

- UL, UR: Underwriters Laboratories inspects and certifies products with respect to their safety

- CSA (in preparation): The Canadian Standard Organization

- Oxygen compatibility (BAM): BAM tests the sealing material compatibility for use in flanged connections with liquid and gaseous oxygen.

- FDA: The US Food and Drug Administration

Features

Material selection

The body materials available for this valve are brass and stainless steel. Suggested media per seal material are as follows:

- NBR: Neutral media, compressed air, water, hydraulic oil

- EPDM: Oil and fat-free media, e.g. hot water

- FKM: Per-solutions, hot oils

Figure 3: Approvals list

Design options

The following options for this solenoid valve are available upon request:

- Flange version in grey cast iron DN 25-50

- Free of oil, grease and silicon

- Stainless steel body: for mildly acidic and alkaline solutions and ultra-pure water or fluids that require high chemical resistance

- Nickel-plated brass body: for mildly acidic and alkaline solutions and ultra-pure water

- Slide ring bearing: to reduce mechanical abrasion in use with dry gases. The sliding rings prevent metallic abrasion between core and core guide tube which increases the service life and stability of the valve.

Port size range

The valve is available with port sizes from G 1/2“ up to G 2“. The table below shows the corresponding orifice sizes and Kv-values. The Kv-value indicates the flow rate of water in m3 per hour with a pressure drop of 1 bar. Correct valve sizing is very important to guarantee good performance of your system and also to optimize costs. Use our valve sizing calculator to quickly determine the right valve size.

| Port size (BSP) | Orifice (mm) | Kv (m3/h) | Pressure (bar) |

| G 1/2" | 12 | 1.8 | 0-16 |

| G 3/4" | 20 | 5.0 | 0-16 |

| G 1" | 25 | 10.0 | 0-16 |

| G 1-1/4" | 32 | 16.0 | 0-12 |

| G 1-1/2" | 40 | 16.0 | 0-12 |

| G 2" | 50 | 38.0 | 0-12 |

Vibration resistance and high performance

In type 0290, the coil is screwed with bolts directly to the valve body. Furthermore, the coil is fully encapsulated in epoxy to ensure high stability in case of strong vibrations. The epoxy is also chemically resistant.

In addition, the valve features a soft-kick function that increases service life. In small diameters of up to DN 25, an elastomer ring provides a dampening function between the core and the main diaphragm, while in larger diameters an additional spring ensures a soft coupling.

Electric power reduction

The Bürkert 0290 features an integrated power reduction (kick and drop electronics) in all UC versions. UC stands for universal current, which means both AC and DC can be used with the same coil. Just after the valve opens, the electric power is reduced far enough that the valve remains open.

Applications

- Mains water protection in industrial applications: Mains water protection systems are activated at nights or on weekends to provide protection against unnoticed leaks in buildings and systems. In these systems, a valve must reliably close the supply to the system during power outages or shut-downs. Since Bürkert 0290 is operational from 0 bar differential pressure and is available in required diameters, it is ideal for use in this application.

- Motor vehicles: Equipment mounted on motor vehicles are often required to be vibration resistant. Often closed cooling systems or gas circuits in motor vehicles have low differential pressure. The type 0290 fulfills these requirements with its vibration-proof block screwed coil and a minimum required differential pressure of zero bar.

- Oxygen applications: in crude steel production process, a water-cooled lance is inserted into the molten metal to inject pure oxygen into the molten mass. This valve type is used both for water cooling and injection of pure oxygen. To prevent a reaction with oxygen in the valve, all media-contacting, non-metal seal materials are designed absolutely oil- and grease-free and are tested accordingly (BAM).