Pressure Safety Valve Vs Pressure Relief Valve

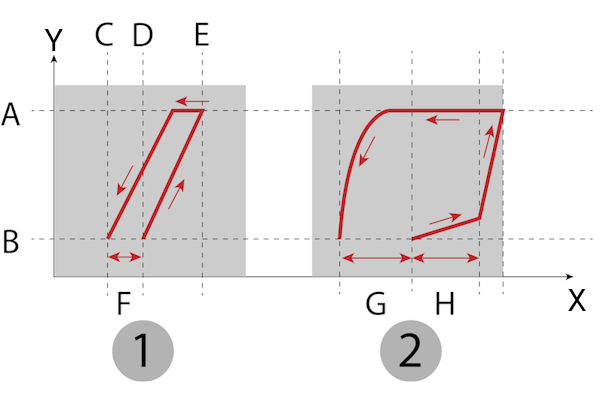

Figure 1: Pressure safety valve (left) and pressure relief valve (right)

Pressure safety valves and pressure relief valves may look similar, but they do different things. Safety valves stop the system if the pressure gets too high and only let it start again when it's safe. Relief valves let out extra pressure without stopping the system. Both help prevent dangerous pressure, but they work differently. This article explains how each one works and their differences.

Table of contents

- What is a safety valve?

- What is a relief valve?

- Difference between a pressure relief valve and a pressure safety valve

- Comparison chart: relief valve versus safety valve

- FAQs

View our online selection of safety and relief valves!

What is a safety valve?

Safety valves are fail-safe devices that automatically stop the increase of pressure beyond a determined limit. They are found in many systems, for example, power plants, petrochemical systems, and boilers. If the pressure reaches the setpoint, the safety valve will fully open until the pressure drops below the setpoint again.

When the media pressure overcomes the pressure safety valve’s cracking pressure, the media encounters the entire closing mechanism (i.e., poppet or disc). This increases the surface area the media flows against, increasing the power against the closing mechanism and opening it rapidly.

Three typical types of safety valves are the direct-acting safety valve, bellows safety valve, and pilot-operated safety valve.

- Direct-acting: A direct-acting pressure safety valve has a spring-supported closing mechanism. The spring is adjustable or non-adjustable and controls the pressure setpoint.

- Bellows: The bellows pressure safety valve has bellows above the poppet, which diffuses and reduces backpressure. Backpressure is pressure building at the valve’s outlet that may flow back into the valve.

- Pilot-operated: The pilot-operated pressure safety valve has a pilot that controls the valve’s pressure setpoint. This type of safety valve allows for a response pressure much closer to the system’s working pressure.

For more information, read our in-depth article on safety valves.

Figure 2: A pressure safety valve at the discharge of a feed gas compressor.

What is a relief valve?

A pressure relief valve proportionally controls system pressure. It protects pressure-sensitive equipment from damage that overpressure causes. A relief valve begins to operate before the system’s pressure reaches unsafe levels. It slows down pressure increases. The valve is fully open when system pressure rises to the relief valve’s pressure setpoint. It prevents the system’s pressure from building further.

Common relief valves are the direct-acting pressure relief valve, balanced pilot-operated pressure relief valve, remote-controlled pressure relief valve, and electrical pressure relief valve.

- Direct-acting: Similar to a direct-acting safety valve, the direct-acting relief valve has a single spring-supported popped that opens to relieve system pressure. The spring is either adjustable or non-adjustable.

- Pilot-operated: A pilot-operated relief valve is similar to a pilot-operated safety valve. The difference between the cracking pressure and pressure setpoint is low compared to the direct-acting relief valve.

- Remote-controlled: A distant direct-acting relief valve controls the adjustable pressure setpoint in a remote-controlled relief valve. Connecting the two valves with a narrow tube achieves this.

- Electric: An electric relief valve system uses solenoid valves to allow or prevent flow from one relief valve to another. This setup allows for the system’s pressure setpoint to change quickly.

For more information, read our in-depth article on relief valves.

Figure 3: Pressure relief valve connects to a reverse osmosis system to limit pressure buildup.

Difference between a pressure relief valve and a pressure safety valve

There are three main differences between pressure relief valves and pressure safety valves: purpose, operation, and setpoint.

Purpose

The purpose of a relief valve is to keep the pressure in a system within set limits to prevent overpressure. Safety valves have a fail-safe purpose to protect people, the environment, and property.

Operation

As seen in Figure 4, pressure relief valves open proportionally to the pressure increase above the setpoint. The valve closes gradually. Safety valves will pop open immediately upon the system pressure reaching the setpoint.

Figure 4: A pressure relief valve (1) opens and closes gradually. A pressure safety valve (2) opens rapidly and does not begin closing until pressure reaches a safe level.

The build-up of pressure is indicated by (Y), and the lift is indicated by (X).

Valve fully open (A), valve fully closed (B), reseating pressure (C), setpoint (D), maximum relieving pressure (E), blowdown pressure relief valve (F), blowdown safety valve (G), simmering period safety valve (H)

Setpoint

The setpoint (response pressure) is the pressure at which the valve starts opening. The setpoint is usually set below overpressure conditions and above the working pressure level. Safety valves open a small amount before the pressure reaches the setpoint and pop open at the setpoint or a specified value after the setpoint. Relief valves start opening at the setpoint.

Design

Basic safety valves and relief valves have nearly identical designs. They have a spring-supported disc that rests on a seat to keep the valve close until system pressure reaches the valve’s set pressure. The spring can be non-adjustable, or it can be adjustable to change the valve’s set pressure.

The most important design difference, which leads to the operation differences, is the disc. A relief valve has a simple disc that rests on the valve seat until pressure builds enough to overcome the spring tension and lift the disc. A safety valve, however, has a lip that the pressure cannot interact with while the valve is closed. When the safety valve cracks, the pressure can reach the lip. Since the pressure is now interacting with a larger surface area, the overall force on the disc increases. This initial increase causes the disc to open to about 60% fully open. If pressure continues to increase, the disc will open further until fully open.

Comparison chart: relief valve versus safety valve

| Relief Valve | Safety Valve |

| Purpose is to limit pressure to a specific pressure | Fail-safe purpose, protect property, environment and people |

| Opens proportional to the pressure increase | Starts opening before the set pressure and pops open at the setpoint or at a defined point |

| Opens when the pressure reaches a set pressure limit | Starts opening before the set pressure limit |

| Can NOT be used at maximal overpressure values of 3% MAWP | Can be used at maximal overpressure values of 3% MAWP |

Table 1: Pressure relief valve vs pressure safety valve chart (Note: MAWP is maximum allowable working pressure.)

When ready to choose a relief valve, safety valve, or both, read our article on selecting and sizing safety and relief valves.

FAQs

What is a pressure or safety valve?

A pressure relief valve regulates pressure increases in a functioning system. A pressure safety valve rapidly reduces the system’s pressure to a safe operating level.

Are relief valves and safety valves interchangeable?

These valves are not interchangeable. A pressure safety valve is a safety device, whereas a pressure relief valve is a control device.