Pressure Relief Valves - A Comprehensive Guide

Figure 1: Pressure relief valve

A pressure relief releases gas or liquid from a fluid system when the pressure exceeds a specified threshold, preventing potential damage. It typically employs a spring-loaded mechanism that opens the valve when the inlet pressure surpasses the set point; this allows the excess pressure to be discharged until it returns to safe levels. These valves are essential in boiler systems, water heaters, chemical plants, nuclear reactors, and hydraulic systems. This article provides a comprehensive overview of pressure relief valves, detailing their design, operating principles, applications, and installation procedures.

Table of contents

- How does a pressure relief valve work?

- How to adjust a pressure relief valve

- Pressure relief valve symbol

- Pressure relief valve applications

- Differences between pressure relief valves and safety valves

- Selection criteria

- Pressure relief valve installation

- FAQs

View our online selection of safety and relief valves!

How does a pressure relief valve work?

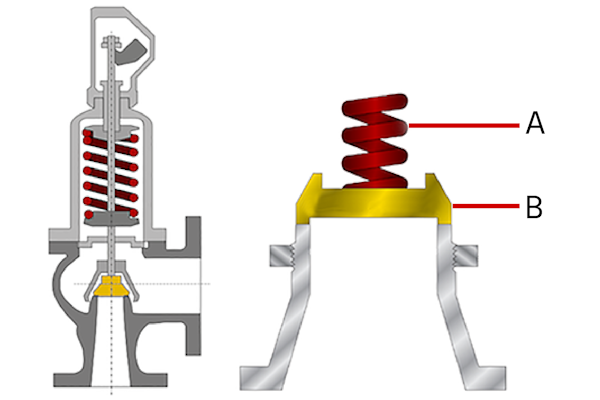

A direct-acting pressure relief valve (Figure 2) has an inlet, outlet, and flow control mechanism (e.g., poppet) supported by an adjustable spring. These valves have two designs for adjusting the spring: external and internal.

- External: An external design allows adjustment of the spring with a knob or handle that bolts onto the valve's outside.

- Internal: An internal design has a nut or screw within the valve's housing that turns in either direction to loosen or stiffen the spring. The internal design requires partial valve disassembly to adjust the spring's stiffness.

A direct-acting pressure relief valve limits pressure in a system rising above a set limit. The valve's spring (Figure 2 labeled A) determines the limit. If the system's media pressure is not high enough, it will not open the valve’s opening mechanism (Figure 2 labeled B).

The opening mechanism activates when the media pressure reaches the valve’s cracking pressure; the valve then discharges the media into the atmosphere, slowing down the pressure buildup in the system.

Finally, when the system's pressure reaches the valve’s set pressure limit, the valve is fully open, and all media discharges through the valve. This stops the operation of any downstream components until pressure reduces enough for the valve to begin closing.

Figure 2: Pressure relief valve diagram (left). Zoomed-in diagram of the valve mechanism (right): spring (A), disc, or poppet (B).

How to adjust a pressure relief valve

To modify the pressure setting of an adjustable pressure relief valve, first locate the adjustment mechanism, which may be a screw or knob. Use the appropriate-sized Allen key to turn the adjustment screw. Rotating clockwise typically increases the pressure setting, while counterclockwise rotation decreases it. Ensure the system is fully depressurized before modifying it to prevent injury or equipment damage.

For example, an adjustable set pressure range of 2-8 bar indicates that the valve can be set to relieve pressure between 2 and 8 bar. Turn the screw within this range to achieve the desired set pressure.

Pressure relief valve symbol

Figure 3: Pressure relief valve symbols: fixed (top) and adjustable (bottom) types

The symbol for a fixed pressure relief valve (Figure 3 top) features a square box with "P" and "R" and a zigzag line, indicating a device that activates at a factory-set pressure to prevent overpressure. The adjustable pressure relief valve symbol (Figure 3 bottom) includes an arrow through the zigzag line, signifying that operators can modify the activation pressure to suit changing process requirements.

Pressure relief valve applications

Avoiding cavitation

Cavitation occurs when the pressure in a liquid drops rapidly below the vapor pressure. If a centrifugal pump pumps against a closed system, overpressure must discharge within the pump housing. This causes areas of low pressure, which can potentially cause cavitation.

By opening proportionally with pressure increases, pressure relief valves bypass the housing. This slowly discharges the excess pressure. By avoiding cavitation, it increases the lifespan of the pump. Learn more by reading our guides on cavitation and flashing and cavitation in pumps, valves, and pipes.

Cooling/heating circuits

Flows may vary significantly with intermittent loads or during startup or shutdown. Reactions from connected boilers or reactors may cause pressure to rise or fall disproportionately to the input generated by user-controlled equipment (e.g., pumps, and heat exchangers). Pressure relief valves help avoid unexpected pressure changes in heating circuits.

Systems with sensitive equipment

Similarly, excessive pressure may damage equipment in pneumatic systems with multiple components. A pressure relief valve can avoid premature equipment failure and be part of a preventative maintenance plan.

Differences between pressure relief valves and safety valves

Pressure relief valves open gradually and keep fluid systems balanced during normal operations. They are part of the system's operations. Safety valves, however, open fully when needed to prevent system failure by releasing excess pressure. They continue to release pressure into the atmosphere until it is safe, even if it drops below the threshold.

The way these valves handle pressure is different. Pressure relief valves close quickly after opening. They close near the set pressure. Safety valves close further from the set pressure and have a slow build-up before they open fully.

Read our article on the differences between pressure safety valves and pressure relief valves to learn more.

Selection criteria

When selecting a pressure relief valve, consider the following criteria. Read our selecting pressure relief valves and safety valves guide for more information.

- Set pressure: The set pressure is the point at which the relief valve opens. Choose a valve with a set pressure range that matches the system's operating conditions. A set pressure that is too low may cause premature opening, while a setting that is too high risks overpressure. An adjustable valve is advantageous if the desired set pressure is unknown or possibly changing during the valve’s lifetime.

-

Body and seal materials: Ensure the valve components are compatible with the media.

- Common body materials are brass and stainless steel. Brass is suitable for general use, offering good corrosion resistance. Stainless steel is ideal for harsh environments, providing superior corrosion and temperature resistance.

- The seal material can be FKM or Teflon. FKM provides excellent chemical resistance and is suitable for high-temperature applications involving oils and solvents, though it is not resistant to methanol, hot water, or steam. PTFE (Teflon) is highly resistant to nearly all fluids but is not flexible.

- Blow-off: Blow-off capacity is the volume the valve can discharge per hour. Ensure the capacity matches potential overpressure scenarios. Insufficient capacity may not relieve pressure quickly enough, while excessive capacity can lead to unnecessary discharge.

Pressure relief valve installation

Pressure relief valves work best downstream of high-pressure zones in a system. A common application is installing a valve near a pump’s discharge. Read our guide on installing pressure relief valves and safety valves for more information.

FAQs

What is a pressure relief valve?

A pressure relief valve limits or controls the pressure in a system. It automatically opens at a set pressure and provides proportional and slow relief.

Does a pressure relief valve reduce flow?

Yes, but this only occurs when the pressure exceeds the set level. During regular operation, pressures should not exceed the set level, and the valve should remain closed.

What do you need to look for when selecting a pressure relief valve?

Maximum flow, maximum pressure, and the nature of the medium. Corrosive media might require different seals, diaphragms, or bodies. Ensure that the valve has the needed approvals for your application.

Can pressure relief valves prevent water hammer?

Yes, certain models can. To fully avoid water hammer, use a specific model that can accommodate both the high flow and pressure differentials common in a water hammer scenario.

What is a pressure relief valve in a water heater?

A pressure relief valve in a water heater is a safety device that releases excess pressure to prevent tank damage or explosion when pressure or temperature exceeds safe limits.

When to replace a pressure relief valve?

Replace a pressure relief valve if it leaks, shows corrosion or damage, fails to open at the set pressure, or is over 3-5 years old, based on manufacturer guidelines and conditions.