Solenoid valve selection guide

Before selecting a solenoid valve, it's essential to thoroughly understand the specific requirements of your application. This guide outlines the critical parameters to consider when choosing solenoid valves. By identifying which parameters are most relevant to your needs, you can efficiently use the webshop's filter to find valves that precisely match your criteria.

View our online selection of solenoid valves!

Important information

These are the most important guidelines when selecting a solenoid valve. Keep these guidelines in mind before choosing a valve.

- Solenoid valves are very sensitive to dirt and only work with clean liquids or air.

- Note that indirectly controlled solenoid valves require a permanent pressure differential of around 0.5 bar to function properly. Therefore, you can not use indirect operated valves in a closed circuit or systems with a low inlet pressure. Direct and semi-direct operated valves operate with a pressure differential from 0 bar.

- Make sure that the used medium and temperature are compatible with the materials of the valve, such as body and the seal materials.

- Solenoid valves open and close fast (between around 10 and 1000 ms). Improper use can cause pressure transients in the system (water hammer).

Important parameters

This is a list of some key parameters that you should take into account when selecting a valve:

- Principle of operation

- Circuit function

- Pipe diameter and thread type

- Orifice, Kv-value and flow rate

- Medium (defines the choice of valve materials)

- Pressure

- Temperature

- Response time

- Voltage

- IP-rating

Principle of operation

There are different types of solenoid valves, each with different principles of operation:

- Direct operated (operating from 0 bar)

- Semi-direct operated (operating from 0 bar)

- Indirect operated (pressure differential required, normally at least 0.5 bar)

It is important to choose the right operation principle. Direct operated valves operate from 0 bar. In the valve there is a small orifice which is sealed off by a plunger with a polymer gasket. If the solenoid (electromagnet) is electrically energized, the plunger is lifted by the electromagnetic force and the valve opens. This principle is often used for small valves and is suitable for small flow rates. For larger flow rates, a semi-direct or indirect operated valve is recommended. Both make use of the medium pressure to open and close the valve. Semi-direct operated valves operate from 0 bar and often have a more powerful coil than indirect operated valves. Indirect operated valves need a permanent pressure differential of around 0.5 bar for proper operation. The advantage of indirectly operated valves is that they usually can control large flows with a relatively small coil and thereby have a reduced energy consumption.

Check if there is a permanent pressure differential over the valve of at least 0.5 bar. In this is the case, an indirect operated valve may be chosen (a semi-direct valve is of course also allowed in this case). If this is not the case (low inlet pressure, closed circuit, ..), choose a (semi-)direct operated solenoid valve.

For a detailed explanation of the operating principles you can read the article about solenoid valve types.

Circuit function

The circuit function expresses which function a valve has in the circuit. The most important circuit functions will be explained.

2/2-way

2/2 way means that the valve has two ports (inlet and outlet port) and two positions (open and closed). Most of the 2/2-way valves are normally closed (or NC). This means that the valve is closed when not powered, and opens as soon as the coil is electrically energized. A normally open solenoid valve (NO) works the opposite way: the valve is open when de-energized, and closed when the coil is electrically energized. The most 2/2-way valves can be used in only one direction of flow. This is usually indicated by an arrow on the housing.

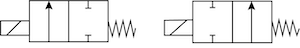

A normally closed 2/2-way solenoid valve (left), and a normally open 2/2-way solenoid valve(right)

The right square indicates the flow in de-energized position, and the left square the energized position. Read the article valve symbols for a more in-depth explanation.

3/2-way

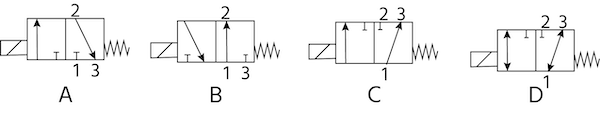

A 3/2 way valve has three ports and two positions. The 3/2-way solenoid valves are usually direct operated and operate from 0 bar. They usually have small orifices, which make them suitable only for small flow rates. If you need a larger orifice, you might consider a 3-way electric ball valve. There are several options for the circuit function, such as normally closed (A), normally open (B), diverting (C) and universal (D). These functions can be visualized by the following diagrams:

Pipe diameter and thread type

The ports of solenoid valves usually have female thread. The type of thread is in most cases British Standard Pipe Parallel (BSPP), denoted by the letter G (for example G1/4 inch). The thread size is given in inches. Please note that this size is not the same as the pipe diameter. The table below shows some standard sizes with the thread data:

| BSP size (in) | thread pitch/inch | thread pitch mm | thread depth mm | outer diameter mm | centre diameter mm | inner diameter mm |

| 1/8 | 28 | 0,907 | 0,581 | 9,728 | 9,147 | 8,566 |

| 1/4 | 19 | 1,337 | 0,856 | 13,157 | 12,301 | 11,445 |

| 3/8 | 19 | 1,337 | 0,856 | 16,662 | 15,806 | 14,950 |

| 1/2 | 14 | 1,814 | 1,162 | 20,955 | 19,793 | 18,631 |

| 3/4 | 14 | 1,814 | 1,162 | 26,441 | 25,279 | 24,177 |

| 1 | 11 | 2,309 | 1,479 | 33,249 | 31,770 | 30,291 |

| 1 1/4 | 11 | 2,309 | 1,479 | 41,910 | 40,431 | 38,952 |

| 1 1/2 | 11 | 2,309 | 1,479 | 47,803 | 46,324 | 44,845 |

| 2 | 11 | 2,309 | 1,479 | 59,614 | 58,135 | 56,656 |

Our range of fittings makes it possible to connect a solenoid valve to almost any kind of piping system:

| Type of pipe | Fitting | Example |

| Gas of water pipe | Compression fitting |  |

| Push-in fitting |  |

|

| Hose tail barb |  |

|

| PVC pipe | PVC fitting |  |

| Polyethylene hose | Compression fitting |  |

| Adapters | Nipple |  |

| Reducer bushing |  |

|

| Adapter |  |

|

| Socket |  |

View our online selection of fittings!

Orifice, Kv-value and flow rate

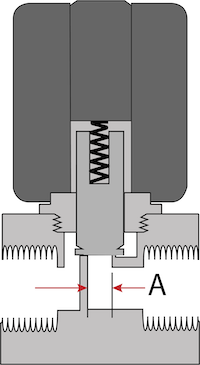

The flow resistance of a solenoid valve is depending on the shape of the valve body and the diameter of the orifice of the valve. The orifice is the diameter (mm) of the hole that will be closed of in the valve, as shown in the sectional drawing below (A). Often this applies: the larger the piping connections of the valve, the larger is the orifice.

The flow resistance of the valve is expressed in the flow coefficient Kv. Read more about Kv in our Kv calculator article. This constant indicates the amount of water in m3/hour that passes the valve at a pressure of 1 bar at 20°C. The higher the Kv-value, the higher the flow rate will be at a given pressure. The flow rate is calculated by the following formula:

Where:

Q = Flow rate [m3/hour]

Kv = Flow coefficient

dp = Differential pressure between inlet and outlet [bar]

SG = Specific Gravity (Water = 1)

Example

A solenoid valve with a Kv-value of 1.25 is connected to a water pipe with a pressure of 2 bar. After the solenoid valve is a pipe of 1m with a free outlet and a negligible pressure drop. Therefore, it is assumed that the pressure drop over the valve is 2 bar. The specific gravity of water is 1. The flow rate can be calculated:

The flow rate is given in m3/hr, but can be converted easily to litres per minute: 1.77*1000/60= 29.5 l/min.

For gases and liquids other than water, other formulas have to used to calculate the flow rate. For the formulas and more explanation, please read the article about flow principles.

For most applications, it is important that the solenoid valve has the right size and flow capacity. The Kv-value is a good selection criteria to choose a valve with the required capacity. If you prefer to choose the right size for the valve intuitively, you can use the orifice or pipe connection size as a starting point.

Medium (determines the choice of materials)

Solenoid valves are used for neutral liquids and gases. These can be for example oils, lubricants, fuels, water, air or steam. When selecting a solenoid valve, it is important that the materials are compatible with the medium. A brass body is the most common for solenoid valve and is suitable for most substances. The seal materials, such as FKM (Viton) and EPDM, each have specific properties that make them suitable for different applications. Read the article about chemical resistance of materials for a complete list of media with compatible valve materials.

Pressure

The operating pressure of the system is important for the choice of a solenoid valve. If the specified maximum pressure is exceeded, dangerous situations may arise and the valve may burst or get damaged. Please note that the maximum pressure is usually associated with a type of medium. So there can be a different values for gasses or liquids. Perhaps even more important is the minimum pressure differential between the in- and outlet (see the section Principle of Operation). The minimum and maximum pressure difference is usually expressed in bar.

Temperature range

Keep the specification of the minimum and maximum temperature in mind when selecting the appropriate solenoid valve. It is recommended not to use water valves below 0°C because of the risk of freezing. The article chemical resistance of materials contains information about the temperature properties of valve materials.

Response time

The response time of a solenoid valve is defined as the interval between the moment of the activation of the solenoid until the pressure has fallen to 10% or raised to 90% of the maximum test pressure. If the maximum rated operating pressure of a valve is higher than six bar, then the response time will be measured at six bar. The response time is depending on the construction of the valve, the coil properties, the atmospheric pressure and the viscosity of the medium. The response time of DC valves is a bit slower than of AC valves. Direct operating valves are generally faster than indirect valves. Common values for direct operated valves are between 5 and 50 ms. For indirect operated valves the response times range from 50 ms for small versions up to 1500ms for large versions. For some applications a short response time is not desired, for example in order to avoid water hammer. Fast closing valves can causes pressure waves in the circuit, which can cause damage to pipes or other components as a result. If this happens in your system, you can read the installation tips.

Voltage and coil

The purpose of the coil of the solenoid valve is to convert electrical energy into motion. The coil is made of copper wire that is wrapped around a tube. In the core is a plunger of ferromagnetic material. When an electric current flows through the coil, a magnetic field is created. The magnetic field exerts a force on the plunger so that it is put into motion. This principle will open or close the valve.

The solenoid coils are available for direct current (DC) and alternating current (AC) at different voltages. The choice has an effect on the characteristic of the valve. The solenoid valves of JP Fluid Control are standardized, which means that most of the coil types can be used in combination with a variety of solenoid valve series.

A frequently asked question is whether the polarity is important for a DC coil. In most cases there is no required polarity for DC coils, only when a timer or LED connector is used, polarity is important for these additional components.

Electrical safety is an advantage of low voltage coils. At higher voltages, the current is lower. AC coils are a little more powerful than DC coils of the same type, due to the inrush properties.

Most of the JP Fluid Control solenoid valves are delivered with a DIN connector. This enables a fast change of the coil and moreover, the coil is well protected against moisture.

IP-rating

The IP rating (Ingress Protection), or IP Code, is a marking on electrical devices that indicates the degree of protection against access to hazardous parts and ingress of water, dust and also body parts. The code is defined in the international norm IEC 60529. The IP rating consists of two digits. The first digit indicates the degree of protection against access to hazardous parts and the ingress of objects. The second digit indicates the degree of protection against moisture. Optionally, a last digit displays the resistance against contact with hazardous components. Most of the JP Fluid Control solenoid valve coils have an IP-65 rating. The table below shows the meaning of the first two digits of the coding.

First digit. Protection against access to hazardous parts and the ingress of objects:

(1) - No protection

(2) - Objects > 50 mm

(3) - Objects > 12 mm

(4) - Objects > 2.5 mm

(5) - Objects > 1.0 mm

(6) - Dust protected

(7) - Dust tight

Second digit. Protection grade against ingress of water:

(1) - No protection

(2) - Dripping water (vertically)

(3) - Dripping water (tilted 15°)

(4) - Spraying water

(5) - Splashing of water

(6) - Water jets

(7) - Powerful water jets

(8) - Powerful water jets high pressure

(9) - Immersion (up to 1m)