Direct Acting Solenoid Valve

Figure 1: Direct acting solenoid valve

A direct acting solenoid valve can function from zero bar upwards, not requiring any pressure difference between the inlet and outlet ports. The valve is commonly used in shut-off, dosing, filling, and ventilation applications. Direct acting solenoid valves are best suited for:

- Applications with low (less than 300 psi), zero, or negative pressures

- Situations requiring quick opening and closing of the valve (Fast startup)

- Tight spaces due to its compact design

- Low flow rate applications, where the orifice diameter is often limited to 25 mm

Table of contents

- What is a direct acting solenoid valve?

- Working principle

- Direct acting solenoid valve disadvantages

- Direct vs indirect and semi-direct solenoid valves

- FAQs

View our online selection of solenoid valves!

What is a direct acting solenoid valve?

A direct acting solenoid valve uses an electromagnetic solenoid to directly move the valve's plunger, which opens or closes the orifice to control fluid flow; it operates independently of line pressure, making it suitable for low-flow and low-pressure applications. They have a simple construction and respond faster since there are fewer moving parts.

Working principle

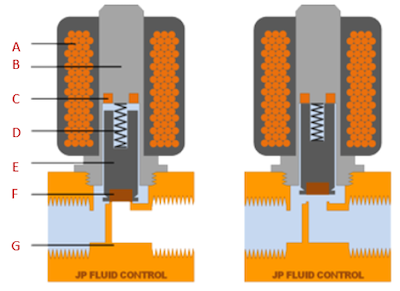

In a normally closed direct acting solenoid valve, the spring (Figure 2 labeled D) exerts a force on the plunger (Figure 2 labeled E), forcing it to block the orifice with the seal (Figure 2 labeled F). When power is applied to the coil (Figure 2 labeled A), it creates an electromagnetic field. This causes the plunger to move up, overcoming the spring force, thus opening the orifice and allowing the media to pass through. A normally open valve has the same components but works oppositely.

Figure 2: Direct acting solenoid valve working principle and components: coil (A), armature (B), shading ring (C), spring (D), plunger (E), seal (F), and valve body (G). This figure shows the valve in the closed (left) and open (right) states.

Direct acting solenoid valve disadvantages

- Limited orifice size and flow rates: The primary orifice must be small because a larger orifice would require a larger coil to generate enough power to move the plunger through a greater media volume. This limits the flow rate. Indirect acting valves are more economical for higher flow rates.

- High power consumption: Maintaining the valve position requires continuous electrical power, which leads to relatively high power usage. Although power can be reduced once the valve opens, initial consumption is high.

- Limited coil life: High-frequency power supplies can cause coils to overheat and burn out, as excessive heat and voltage spikes can damage the coil and its insulation, causing electrical issues.

Direct vs indirect and semi-direct solenoid valves

Direct acting solenoid valves are simple and fast-acting but limited to smaller flow rates and lower pressures. Indirect acting valves allow higher flow rates and pressures but slightly slower response times. Semi-direct acting solenoid valves balance the quick response of direct acting valves and the higher flow capacity of indirect types. Table 1 summarizes the various factors to consider when selecting solenoid valve types.

Table 1: Comparison between direct acting, indirect acting, and semi-direct acting solenoid valves

| Solenoid valve type | Pressure tolerance | Pressure difference | Speed | Power consumption | Coil life | Flow capacity | Purity of media | Cost |

| Direct acting | Suitable for low-pressure, zero, and negative pressures | No required pressure difference | Fast | High | Less | Low | Can handle more fluid debris than indirect or semi-direct, but a strainer is still advised. | Low initial cost for low flow rate systems, cost increases as the flow rate increases |

| Indirect acting | High-pressure applications. | Minimum pressure differential of 0.2 - 0.5 bar (3 to 7.3 psi) | Slow | Low | Medium | High | Debris can clog the diaphragm. Using a strainer can increase back pressure and reduce efficiency. | Economical for large flow rate systems |

| Semi-direct acting | Suitable for low and high pressures | No pressure difference required | Medium | Low | High | High | Debris can clog the diaphragm. Mounting a strainer before the solenoid valve can avoid clogging. | Economical for large flow rate systems |

FAQs

What does a direct acting solenoid valve do?

A direct acting solenoid valve uses an electromagnetic solenoid to directly open or close the valve, controlling fluid flow without requiring any pressure difference between the inlet and outlet ports.

What is the difference between direct acting and pilot solenoid valves?

Direct-acting valves use electromagnetic force directly, needing no pressure differential, and are ideal for low pressure. Indirect valves, on the other hand, need fluid pressure to assist and require a pressure differential, which is suitable for high pressure.