Solenoid Valve Accessories Overview

Figure 1: Solenoid valve accessories from left to right: solenoid coil, solenoid DIN connector, solenoid valve timer, and spare parts found in a solenoid valve revision set.

Solenoid valve accessories protect and provide extra functionality to solenoid valves. The typical accessories are extra coils, timers, revision sets, connectors, and filters. This article provides an overview of the accessories and offers advice on how and when they are used.

Solenoid valve accessories

Different solenoid valve accessories have different functions and suitability for specific applications. This section will cover the various accessories, describing how they work and in what applications they are typically used:

- Solenoid valve coil

- Solenoid valve connector

- Solenoid valve timer

- Solenoid valve revision set

- Filters for solenoid valves

Solenoid valve coil

Solenoid valves get their name from the coil, which is called a solenoid. Most solenoid valves have a coil that can be replaced with another, even one of a different voltage rating.

A major benefit of being able to replace a coil in a solenoid valve is being able to match the power source. For example, a DC coil in a solenoid valve can be replaced with an AC coil if necessary, and vice versa. Our guide on ac vs dc coils for solenoid valve explains the differences.

Figure 2: A 230V AC solenoid coil

Solenoid valve connector

Solenoid valve DIN connectors have three forms: Form A, Form B, and Form C. Our article on solenoid valve connectors covers in-depth the design and operation differences among the three forms.

Solenoid valve connectors have different circuit functions that serve different purposes. For example, varistors are a common and probably necessary circuit function. A varistor protects the solenoid valve from power spikes that can damage it, saving on expensive valve replacement costs. Other circuit functions include:

- Connector with LED: The LED light on the connector clearly indicates the valve's power level.

- Pole protection and freewheeling diode: This circuit function eliminates arcing across a switching DC power supply, protecting it from transient voltage spikes.

- Rectifier: A rectifier converts approximately 90% of AC into DC, allowing a DC coil solenoid valve to operate with an AC power source.

Figure 3: A solenoid valve DIN connector with LED

Solenoid valve timer

A solenoid valve timer automates a solenoid valve's on and off intervals. This allows for precise and flexible flow control as the timer can be adjusted to operate with several different intervals. For example, the timer can set the solenoid valve to be on between 0 and 10 seconds and off for between 0 and 45 minutes. These intervals can be programmed as cycles or single events.

Solenoid valve timers are used in applications that require precise flow control. For example, air dryers and showers use timers to control how long the devices operate. Condensate drains use timers to control how long the condensate can drain, ensuring enough condensate can drain without interrupting the compressed air system.

Figure 4: An analog solenoid valve timer

Solenoid valve revision set

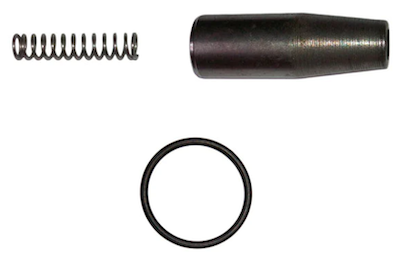

A huge advantage of solenoid valves is that many components can be replaced, avoiding replacing the entire valve. The more vulnerable components are the solenoid valve plunger, o-ring, spring, and diaphragm (in the case of indirect acting solenoid valves). Solenoid valve operators should purchase revision sets with these replacement parts, ensuring the parts are identical to those in the valve.

Figure 5: Common components of a solenoid valve revision set: plunger spring, plunger, and o-ring.

Filters for solenoid valves

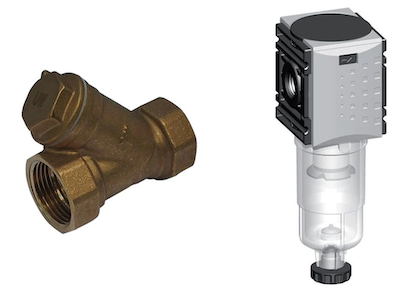

Filters and strainers remove particles and contaminants from media before they can clog and potentially damage solenoid valves. There are a variety of filters and strainers available for different solenoid valve applications:

- Strainers: Y strainers and t strainers clean media in fluid systems.

- Pneumatic air filters: Pneumatic filters remove dirt, water, and other harmful contaminants from compressed air.

- Pneumatic silencers: Also called pneumatic mufflers, pneumatic silencers vent air to the atmosphere to control pressure in the system. Also, they prevent debris from entering through the vent, which could damage the valve.

Figure 6: A y strainer (left) and pneumatic filter (right) are used to keep hazardous particles out of a solenoid valve

FAQs

What are solenoid connectors?

Solenoid valve connectors have circuit functions that protect the valve from power surges. They allow DC coil valves to work with AC power supplies and more.

Does my solenoid valve need a filter?

If the media interacting with the solenoid valve contains particles that can clog the valve, a filter or strainer is necessary to protect the valve from damage.