Hand Slide Valve - How It Works

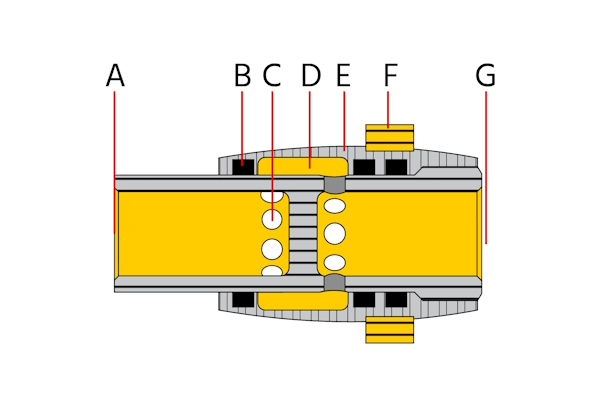

Figure 1: Festo's VBOH hand slide valve

Hand slide valves manually control the flow of air through a simple yet effective mechanism. By moving the slide plate within the valve body, users can open, close, or regulate the airflow, making these valves versatile for various applications such as pneumatic cylinders, air tools, and in-line flow control. Festo's VBOH hand slide valve exemplifies robust design and adaptability, featuring threaded pneumatic connections, a wide operating pressure range, and durable materials like anodized wrought aluminum alloy and PBT.

Hand slide valve design

Hand slide valves' construction includes several essential components that ensure proper functionality and durability. As seen in Figure 2, their key components are:

- Inlet & outlet (A & G): The inlet and outlet are threaded, one male and one female.

- Seals (B): Located around the slide plate, seals, such as o-rings, prevent leaks and ensure a tight closure when the valve is in the closed position, maintaining system pressure.

- Exhaust (C): The exhaust ports are under the valve body, protecting them from dirt and debris.

- Slide plate (D): A movable component that slides within the body to open or close the flow path. It is the primary mechanism for controlling the flow of compressed air.

- Body (E): The main structure that houses all other components. It provides the framework and support for the valve.

- Grip ring (F): Attached to the slide plate, the grip ring allows the user to manually move the slide plate to the desired position, regulating the airflow.

Figure 2: The typical hand slide valve components are the inlet (A), seals (B), exhaust (C), slide plate (D), body (E), grip ring (F), and outlet (G).

Operating principle

Hand slide valves in compressed air systems operate on a straightforward principle. They control the flow of compressed air by manually moving a slide plate within the valve body. Here’s how they work:

- Opening the valve: When the grip ring is moved to the open position, the slide plate shifts, creating a clear path for the compressed air to flow through the valve.

- Closing the valve: Moving the grip ring to the closed position slides the plate back, blocking the flow path and stopping the airflow.

- Exhaust: When the hand valve is closed, the outlet connects to the exhaust port, exhausting air from the valve, typically to the atmosphere.

- Regulating flow: By partially opening or closing the valve, the user can regulate the amount of compressed air passing through, allowing for precise control of the system.

- Sealing: Seals around the slide plate ensure that when the valve is closed, no air leaks through, maintaining system pressure and efficiency.

Hand slide valve applications

A pneumatic hand slide valve can be installed in various applications to control the flow of compressed air. Here are some common uses and installations:

- Pneumatic cylinders: Used to control the airflow to pneumatic cylinders, allowing for precise control of the cylinder's movement.

- Air tools: Installed to control the airflow to air tools.

- In-line flow control: Often installed in-line within pneumatic systems to act as an ON/OFF mechanism for controlling the flow of air.

- Pneumatic installations: Used to section off parts of a pneumatic installation, allowing for maintenance or isolation of specific sections.

- Compressed air systems: Installed as a shut-off function for pressurizing and exhausting compressed air systems.

- Air compressors: Commonly installed near the air compressor to control the airflow right as it exits the compressor.

- Air lines: Used to isolate air lines and exhaust downstream pressure, ensuring safety and control within the system.

Festo hand slide valves

Festo's VBOH hand slide valve is robust and suitable for many applications. It has the following properties:

- Pneumatic connections: Threaded (M5, G1/8 - G3/4)

- Valve function: 3/2 way

- Mounting type: Screw in, in-line

- Nominal width: 3.6 - 19.3 mm

- Operating pressure: -0.95 to 12 bar (-13.7 to 174 psi)

- Lubrication: Possible but afterward will always be required

- Ambient/Medium temperature: -10 to 80 °C (14 to 176 °F)

-

Material

- Screwed trunnion: Anodized wrought aluminum alloy

- Housing: Anodized wrought aluminum alloy

- Grip ring: PBT

- Seals: NBR

- Common applications: Shut-off function for pressurizing and exhausting compressed air systems, for example upstream of service unit component combinations, for air guns, and also for exhausting pneumatic cylinders

FAQs

What is a pneumatic hand slide valve?

A pneumatic hand slide valve manually controls air flow by moving a slide plate within the valve body, allowing for opening, closing, or regulating airflow.

What are the applications of a hand slide valve?

Hand slide valves are used in pneumatic cylinders, air tools, and in-line flow control, providing versatile and manual control of air flow.