Learn How To Cut Steel Pipes & Buy a Steel Pipe Cutter

Figure 1: A stainless steel pipe cutter.

A handheld steel pipe cutter is a convenient solution for cutting steel pipes on any work site because it readily performs without electricity. A common steel pipe cutter can be seen in Figure 1. Although power tools, such as a circular saw, cut much faster, the need for electricity adds complexity to the task making a handheld pipe cutter suitable for applications away from a workshop or electricity.

Table of contents

Check out our selection of pipe and tube processing tools!

Steel pipes

Manufacturing and construction industries use steel pipes for many purposes. For example, steel tubes that operate the cooling in a fridge or scaffolding for a renovation project of an old building. During the installation of a plumbing system, steel pipes are cut to install fittings, such as elbows.

Steel is a hard alloy and therefore is difficult to cut. Fast solutions to cutting steel, such as circular saws, are expensive. Also, power tools require an electricity source, adding complexity to the cutting process. A pipe cutter is a slower alternative to power saws but is readily available at any work site.

What is a pipe cutter?

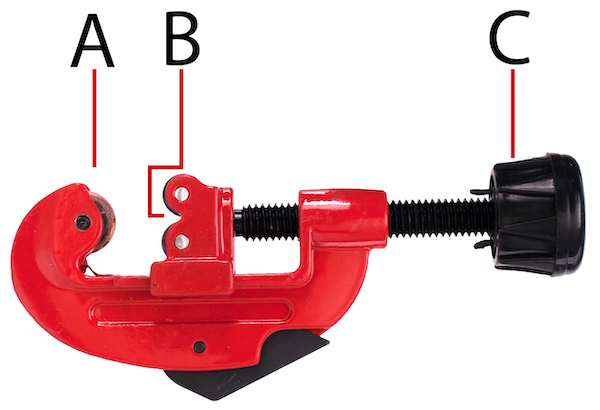

A pipe cutter is a C-shaped, handheld tool that uses a hardened steel cutting blade to cut a metal pipe. The pipe fits between the cutting wheel (Figure 2 labeled A) and rollers (Figure 2 labeled B). The rollers allow the pipe cutter to spin around the pipe without turning the pipe. Some pipe cutter designs allow cutting blades to replace the rollers to create a 3-point cutting tool. A user rotates the tightening knob (Figure 2 labeled C) or the handle to clamp the device onto the pipe. Then, the user spins the tool around the pipe until the cut is complete. To learn more about pipe cutters, please see our pipe cutter article.

Figure 2: A pipe cutter with components: cutting wheel (A), rollers (B), and tightening knob (C).

How to cut steel pipes with a pipe cutter

There are several tools available for cutting steel pipes. No matter which tool, PPE (personal protective equipment) is important. For hand tools, wear gloves and safety glasses. When using power tools that cause sparks, also wear a face mask. Finally, no matter which tool, deburr the edge of the steel pipe after cutting it.

This section looks at how to use a steel pipe cutter and then compares its effectiveness to other tools such as:

- Hacksaw

- Miter saw

- Reciprocating saw

- Circular saw

Steel pipe cutter

A steel pipe cutter’s thicker and harder cutting blade makes it different from other metal pipe cutters (e.g., copper pipe cutter). Most steel pipe cutters work for pipes up to 50 mm (2 in) diameter. Some designs are large enough for 76 mm (3 in) diameter pipes.

Steel pipe cutters are the best tool for cutting steel pipe. They make a square (90°) cut and leave a smooth finish that requires minimal deburring. However, pipe cutters are much slower at cutting than power saws. So, if a job requires a lot of cutting, consider one of the power tools discussed later in this section.

The following steps describe how to cut steel pipe with a steel pipe cutter:

- Place the head of the steel pipe cutter around the pipe and tighten it until the cutting blade makes contact with the pipe’s surface.

- Spin the steel pipe cutter around the pipe to begin the cut groove.

- After one or two spins around the pipe, push the cutting blade into the groove using the tightening knob or handle.

- Repeat spinning and tightening until the cut is complete.

- Use a deburring tool or the deburrer attached to the steel pipe cutter to deburr the end of the cut pipe.

Steel pipe cutter vs steel tube cutter

When it comes to cutting steel pipes and tubes, a steel tube cutter is the same tool as a steel pipe cutter. The difference between a pipe and a tube is how the diameter is measured. The diameter of a pipe is its inside diameter, often called nominal diameter. The diameter of a tube is its outside diameter. Also, tubes come in different shapes (e.g., round, square, or oval), whereas pipes are always round. If the name of a tool is simply tube cutter, it is more than likely a tool for cutting plastic tubes.

Other tools for cutting steel pipe

Hacksaw

A hacksaw is a special type of saw for cutting metal. Using a hacksaw to cut a steel pipe can be precise with the additional use of a guide. The saw blade fits in the guide, which keeps the blade in the same position on the pipe and prevents the blade from jumping. Ensure that the hacksaw blade can cut through steel. Read our hacksaw blade selection article to learn more about choosing the right blade.

To cut steel with a hacksaw:

- Use short strokes with the middle of the blade to create a groove in the pipe’s surface.

- Once there is a groove, use the blade's full length to saw the steel pipe.

- Apply pressure on forward strokes. Most hacksaw blades do not cut on the backstroke.

- Finish the cut and deburr the pipe end.

For more information on how to use a hacksaw, read our hacksaw overview article.

Reciprocating saw

A reciprocating saw, commonly called a Sawzall, is an efficient tool for cutting through steel pipes. Ensure that the blade of the saw is a hard metal cutting blade. Reciprocating saws do not accurately cut, though. So for cutting steel pipes, these saws are best for demolition work.

Circular saw

Circular saws can quickly cut through steel pipes. Ensure the saw’s blade is meant for cutting hard metal. Before cutting, ensure that the steel pipe is clamped down. Also, take extra care with a circular saw. Because it can quickly cut through steel pipes, users sometimes go too fast and make costly mistakes while cutting.

Steel pipe cutter advantages

Although it does not cut through steel pipes as fast as power saws, a steel pipe cutter still has distinct advantages:

- Cost: Steel pipe cutters cost much less than power saws.

- Finish: Steel pipe cutters leave the smoothest finish, requiring the least amount of deburring after the cut.

- Accuracy: Steel pipe cutters make the most accurate and square cuts.

- Readiness: Steel pipe cutters are always ready to use since they do not require a power source.

Steel pipe cutter disadvantages

Steel pipe cutters have the following disadvantages:

- Speed: Of all the pipe cutters, steel pipe cutters are the slowest.

- Availability: Most users likely already have a hacksaw available, whereas pipe cutters are less common due to their specific application.

Steel pipe cutter advice

The following tips are useful for anyone buying or using a steel pipe cutter:

- Typically, the larger the frame of the tool, the larger and thicker the cutting blade. Therefore, larger pipe cutters are better suited for steel pipe but not softer pipes like copper.

- A small spray of lubricant (e.g., WD-40) reduces friction and heat during the cutting process.

- Replace worn or damaged cutting blades immediately.

Read our copper and PVC pipe cutter articles for more information on pipe cutters for copper and PVC.

FAQs

Can a pipe cutter cut steel pipe?

Large pipe cutters with hardened steel cutting blades are suitable for cutting steel pipe.

Can a copper pipe cutter cut steel pipe?

Check with the copper pipe cutter’s manufacturer before trying to cut steel pipe with it. The copper pipe cutter’s cutting blade may be too small to efficiently cut steel pipe. Also, cutting steel pipe may add undue wear on the copper pipe cutter’s cutting blade.