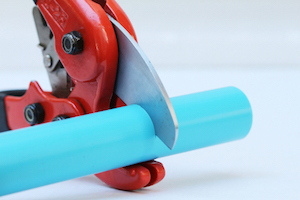

Tube Cutter

Figure 1: Tube cutter

A tube cutter is an effective tool for cutting tubes to a certain length. Tube cutters and pipe cutters are often used interchangeably on tubes and pipes. However, there are a few key differences between both device types. This article explores how to use a tube cutter to cut and deburr a copper pipe and how the tool differs from a pipe cutter.

Table of contents

- What is a tube cutter?

- Pipes vs tubes

- Tube cutting process

- Cutting other materials

- Pipe cutters vs tube cutters

- FAQs

Check out our selection of pipe and tube processing tools!

What is a tube cutter?

Tubes carry water and other fluids through airplanes. Also, medical devices require tubes with a precise outside diameter.. Tube cutters have a set of jaws with a blade to cut tubes. There are different tube cutter types, but most work the same way. The jaws close and drop the blade on the tube. The choice of tube cutter depends on the tube’s material, outer diameter, and wall thickness. They can function manually, pneumatically, electrically, or hydraulically.

Tube cutter specifications

Tube cutters come in different sizes to accommodate different tube lengths and widths. Mini tube cutters have steel or zinc blades. These blades cut copper, plastic, brass, or aluminum plumbing pipes. Heavy-duty tube cutters can cut stainless steel, cast iron, or plastic tubes of larger diameters.

Pipes vs tubes

The terms ‘pipes’ and ‘tubes’ are often interchangeable; however, it is important to understand their key differences to choose the right structure for an application.

- Shape: A pipe is always round; tubes can be square, rectangular, or round.

- Measurement: Diameter measurements use internal diameter for pipes and outside diameter for tubes. A tube’s outside diameter determines its stability factor and holding ability. A tube’s wall thickness determines its strength. Therefore, outer diameter and wall thickness specify tubes.

- Application: Tubes support structures in applications like medical devices. Pipes typically transport liquids or gasses. The round shape of a pipe makes it efficient in handling the fluid pressure within its structure.

Tube cutting process

Materials needed

- Sandpaper

- A tape measure

- A marker or pencil

- Tube cutter

- Most tube cutters contain a sharp blade to cut the burrs of the tube. If not, make sure to have a file for deburring the tube.

Measuring length

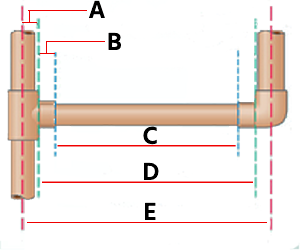

Measure the length of tube needed for the application. There are a few parameters to consider when measuring pipes or tubes, especially when replacing them between two sockets.

- Laying length (Figure 2 labeled A): Laying length, also known as fitting gain, is the distance between the bottom of the fitting socket and the centerline of the pipe. This is the extra length the fitting adds to the pipe. Check the laying length on the fittings; the length varies based on fitting styles and manufacturers.

- Socket depth (Figure 2 labeled B): Socket depth is the distance from the bottom of the fitting to the fitting face. This indicates the length of pipe which fits into the fitting.

To quickly figure out the pipe length (Figure 2 labeled D), use one of these methods:

- Measure the face-to-face distance (Figure 2 labeled C) between the fittings and add twice the socket depth (B).

- Measure the center-to-center (Figure 2 labeled E) distance between the two pipes and subtract the total of the laying lengths (A) of the fittings at both ends.

Figure 2: Tube/pipe measurement diagram: laying length (A), socket depth (B), face-to-face distance (C), pipe length (D), and center-to-center distance (E).

How to use a tube cutter

Before using a tube cutter, measure the tube and mark the region to be cut. Then perform the following steps:

- Position the tube in the tube cutter and tighten the blade just enough so it is snug; the tube may bend if the device gets too tight.

- Give the tube a few turns with the cutter and pull out the tube to inspect it. There should be a groove cut around its circumference.

- Once the cutter sits correctly, slide the tube through the tube cutter so that the groove aligns with the blade, and tighten it once more until it’s just snug.

- Turn until the tube is cut.

When done, use the tube cutter’s built-in burr removal tool to shave any burrs or raised lips on the inside of the tube, as those would inhibit smooth water passage. Finally, use sandpaper to make the tube end smooth. Make sure to rinse the tube before use so that no filings or metal residues get into the system.

Cutting other materials

Tube cutters generally cut materials like plastic and copper. Most tube cutter designs cut only one kind of material. They can also cut other materials, but always confirm the usability by referring to the manufacturer’s sheet. Using a tube cutter on the wrong material can potentially damage or even destroy the tube cutter’s blades. A tube cutter is a standard tool for working with various hoses and tubes and fittings.

Pipe cutters vs tube cutters

Tube cutters and pipe cutters are interchangeable. However, it is important to note the key differences between both tool types to choose the correct device for the pipe/tube.

- Materials: Tube cutters typically cut through soft materials such as PVC. Pipe cutters are more suitable for cutting hard materials like steel and iron.

- Method of operation: Tube cutters have a set of jaws with a blade. The blade drops onto and slides through the tube, cutting it. Since tube cutters cut softer materials, they can cut straight through the tube as the material is malleable. As pipe cutters are made to cut metals, the tools cut pipes in a circular motion to prevent them from cracking. Unlike tube cutters, they don’t have a blade that drops on the pipe. The user places a pipe inside of a pipe cutter. The wheel cuts the pipe from its sides as the tool turns.

- Blade and wheel: A tube cutter’s blade is made of stainless steel, whereas a pipe cutter’s cutting wheel is made from hardened and tempered steel, which is much stronger.

In general, a pipe cutter is suitable for pipes and tubes. However, a tube cutter may not work on pipes made of hard materials like iron or steel.

Figure 3: Using a pipe cutter to cut a copper pipe

FAQs

What is a tube cutter used for?

A tube cutter cuts tubes made from plastic into desired lengths.

What is the difference between a pipe cutter and a tube cutter?

Tube cutters have a set of jaws with a blade. The blade drops on the tube and slides through the tube, cutting it. However, a pipe cutter’s wheel cuts the pipe from its sides as the tool is turned.