Pipe Cutter - How To Use It

Figure 1: Using a pipe cutter to cut a copper pipe

A pipe cutter is a specialized tool used for cutting pipes. It provides a clean and precise cut, which is often more difficult to achieve with a hacksaw. Pipe cutters come in various designs and sizes, tailored for different types of pipes and materials, such as copper, PVC, steel, and plastic. This article explores the different types of pipe cutters, how to choose one for an application, and how to cut a pipe using the tool.

Table of contents

- What is a pipe cutter?

- Pipe cutter types

- Auto-cut tool

- How to use a pipe cutter

- How to choose a pipe cutter

- How to replace the wheels on a pipe cutter

- FAQs

View our online selection of pipe and tube processing tools!

What is a pipe cutter?

A pipe cutter uses a sharp cutting wheel to penetrate through the pipe material and slowly cut through it. The wheel penetrates further into the pipe with each rotation. Cutting through soft materials like copper and aluminum takes only a few rotations to complete. Harder materials like steel require considerably more rotations depending on their thickness. Compared to hacksaws, pipe cutters are more convenient, faster, and provide cleaner cuts that need minimal deburring.

A wide range of applications uses pipe cutters, including:

- Carrying out pipe repair works

- Cutting pipes to desired lengths for installations

- Cutting out and replacing damaged sections of pipework

Pipe cutters can cut a variety of materials, such as copper, aluminum, and brass, and, with the appropriate heavy-duty versions, even steel and iron. The following sections explore some common pipe cutter types and their uses.

Pipe cutters vs tube cutters

While both tools are used to cut cylindrical objects, pipe cutters are generally designed for thicker-walled pipes, whereas tube cutters are more suitable for thinner-walled tubes. Tube cutters often provide more precision and are used in applications requiring exact measurements.

Pipe cutter types

Based on the material being cut, there are different pipe cutters, like plastic, copper, aluminum, steel, and brass. Pipe cutters are also classified based on their construction and application.

Auto-cut tool

An auto-cut tool (also called a ‘wheel cutter’) is a compact, hand-powered cutter in the shape of a wheel. Using one hand to operate the tool is helpful while working in tight spaces.

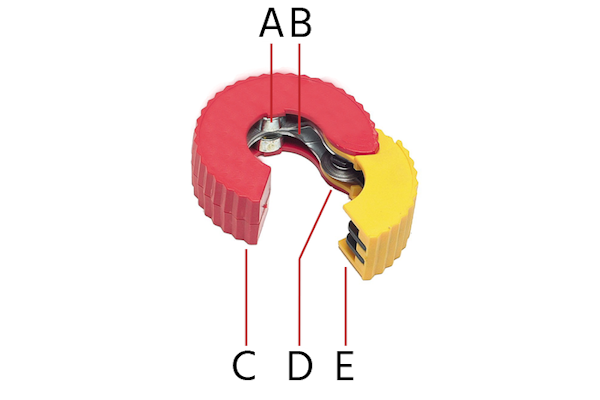

The parts of a single-handed pipe cutter are:

- Rollers (Figure 2 labeled A): The rollers spin around the surface of the pipe as the pipe cutter rotates. This stops the pipe from turning as the cutter rotates.

- Framework (Figure 2 labeled B): The framework holds all the parts together within an outer casing.

- Main body (Figure 2 labeled C): The pipe cutter’s main body protects the cutting wheel.

- Wheel (Figure 2 labeled D): The pipe cutter’s wheel cuts the pipe. In some designs, the wheel sits on a spring which keeps the wheel constantly pressed on the pipe while cutting.

- Gate (Figure 2 labeled E): Certain single-handed pipe cutters have a gate. The cutter fits around the pipe, and then the gate connects to the cutter. This creates a full circle and ensures that the cutter does not fall off while in use.

Some auto-cut tools can turn to only one side to cut the pipe. The main body of the tool indicates the direction of the cut. Others can turn in both directions to cut a pipe. The inner framework of a single-handed pipe cutter is usually made of steel. The shell is generally made of ABS plastic or zinc. Zinc is stronger than plastic but comes at a higher price.

Auto-cut tools mainly cut copper and soft metals like brass or aluminum (if stated on the tool). However, they do not cut steel. The tools are available in multiple sizes to match the standard pipe sizes. The term ‘size’ usually refers to the distance between the cutter’s jaws where the pipe sits. For example, a 22 mm (0.8”) auto-cut tool has a distance of 22 mm between its jaws.

Figure 2: Auto-cut tool: the rollers (A), framework (B), main body (C), wheel (D), and gate (E).

Ratchet pipe cutter

A ratchet pipe cutter has a ratchet handle and a head similar to a single-handed pipe cutter. Ratchet pipe cutters facilitate slight adjustments to the size of pipes being cut. They are not made for one particular pipe size. The user turns the adjustment handle of a ratchet pipe cutter to adjust the tool to the correct size for the pipe. Therefore, the size of these cutters is usually specified within a range. For example, a ratchet pipe cutter of size 6 mm (0.2″) – 23 mm (0.9″) can work on pipe sizes between both values.

Ratchet pipe cutters can cut soft materials like copper, brass, PVC, and aluminum. However, the tool is not strong enough to cut steel. Ratchet pipe cutters don’t need to do a full circle around the pipe to cut. Hence, the tool is useful in tight areas where there are several pipes close together.

Figure 3: A ratchet pipe cutter cutting through copper pipe.

Adjustable pipe cutter

As the name suggests, an adjustable pipe cutter has a screw handle to fit the pipe cutter to various pipe sizes. Turning the handle moves the cutting wheel backward or forward. This helps accommodate different pipe sizes. The tool is helpful if the user needs to cut pipes of different lengths frequently. A single adjustable pipe cutter can replace several tools.

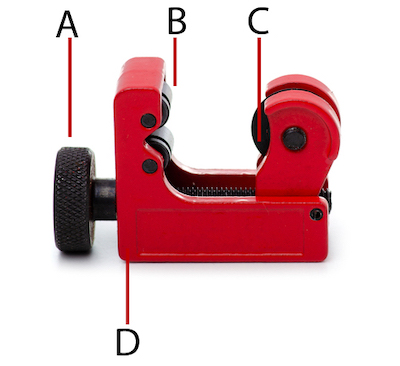

The main parts of an adjustable pipe cutter are:

- Tightening knob (Figure 4 labeled A): The knob rotates both ways to move the blade forward or backward.

- Rollers (Figure 4 labeled B): The pipe rests upon two rollers. They spin around as the cutter rotates, preventing any movement of the pipe from its initial position.

- Wheel (Figure 4 labeled C): The wheel cuts the pipe.

- Main body (Figure 4 labeled D): An adjustable pipe cutter’s main body fits over a pape so the rollers and blade can touch the pipe.

To keep the cut going, turn the handle after every couple of turns. The tool can cut different materials like copper, aluminum, and brass. The heavy-duty version of adjustable pipe cutters can cut strong iron and steel piping. Often extra cutting wheels are used in place of rollers to help cut strong pipes. Also, these pipe cutters have longer handles to provide extra pressure on the cut. Certain heavy-duty models have two handles which makes leverage by two people possible.

Figure 4: Adjustable pipe cutter: Handle (A), rollers (B), wheel (C), and main body (D).

Power pipe cutter

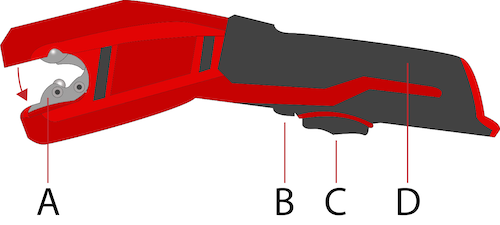

A power pipe cutter has a battery-powered motor. The motor powers the cutting wheel. The tool cuts pipes quickly and effortlessly. The main parts of a power pipe cutter are:

- Jaws with wheel blade (Figure 5 labeled A): The jaws hold the pipe while it is being cut.

- Control switch (Figure 5 labeled B): The control switch selects an operation mode for the power pipe cutter. For example, the power button (Figure 5 labeled C) functions only when the control switch is put in the cutting mode. Other modes like locking mode (to lock the device when not in use) vary between different power pipe cutters.

- Power button: Pushing the power button starts the motor to operate the pipe cutter.

- Handle grip (Figure 5 labeled D): The rubber coating on the handle provides additional grip, especially for wet hands.

Figure 5: Power pipe cutter: jaws with wheel blade (A), control switch (B), power button (C), and handle grip (D)

How to use a pipe cutter

Pipe cutters contain a sharp wheel that cuts through the pipe as it rotates. The number of wheel rotations needed to cut through the pipe completely depends on various factors like:

- A pipe’s material, size, and thickness

- The sharpness of the pipe cutter’s blade

Cutting a pipe varies slightly depending on the type of pipe cutter. The following steps are common for cutting a pipe:

- If the pipe is part of a plumbed-in system, turn off the water supply before starting the cutting process.

- Place the cutter around the pipe.

- In the case of an adjustable pipe cutter, tighten the tool around the pipe to get the correct fit.

- If the cutter is non-adjustable (like an auto-cut tool), simply ensure that the tool grips the pipe perfectly.

- Rotate the tool to cut the pipe. Take care not to let the cutting blade slip, as the motion can result in an uneven cut.

- If the cutting blade is not spring supported to automatically tighten against the pipe, tighten the tightening knob after every two rotations.

- Once the pipe is cut, use a deburring tool to clear any sharp edges and ensure that the pipe edges are smooth and clean.

- Clean the pipe cutter after use.

How to choose a pipe cutter

As discussed in the previous sections, there are different pipe cutters based on their construction. Choosing one for a particular application requires the user to consider several factors.

- Single-handed pipe cutters are preferred for DIY projects or when working in small spaces. They are cheaper than other pipe cutter types.

- A ratchet pipe cutter is helpful when working in hard-to-reach areas or spaces that are too small for the tool to completely rotate around the pipe. The handle renders extra strength to the tool, and it is useful in areas where the pipe cutter tends to fall off the pipe.

- Choose an adjustable pipe cutter (and not an auto-cut tool) if the pipe cutter needs to be used often on different pipe sizes. They are suitable for cutting heavy-duty materials like steel and iron and have a longer life than other pipe cutter types.

- A powered pipe cutter is the best option when the tool needs to be used for long periods as the cutter requires little effort from the user. However, the tool's blades dull out quickly as it goes through multiple rotations per cut.

How to replace the wheels on a pipe cutter

A pipe cutter’s wheel can go blunt with continuous use and, if used on pipe materials, unsuitable for the tool. Perform the following steps to replace the wheel with a new one:

- Remove all the screws from the pipe cutter.

- Pull the metal body out of the casing.

- Remove the pin in the center of the wheel carefully and pull out the wheel.

- Insert the new wheel into the position and push the pin back into the wheel hole.

- Place the metal body back inside the casing and screw the tool back together.

FAQs

What is the use of a pipe cutter?

Pipe cutters slice pipes efficiently, providing a clean and professional cut.

Do pipe cutters work on steel?

Yes, choose heavy-duty pipe cutters to cut steel pipes.

What is the best way to cut a metal pipe?

Use pipe cutters to slice metal pipes. Choose a reciprocating saw for tight spaces.