Couplings

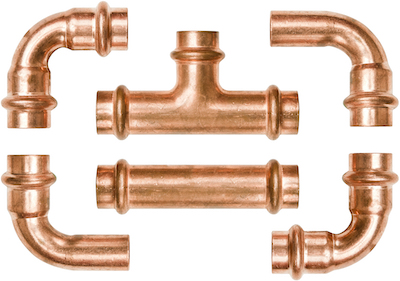

Figure 1: Mold coupling

A coupling is used to connect hoses, pipes, fluid control components, and more for various types of applications. Couplings are typically connection and/or application-specific, so be sure to review your application's specifications, product material, and pressure specifications. This article discusses the various coupling types used across industries.

Table of contents

- Storz couplings

- Camlock couplings

- Guillemin couplings

- Mold couplings

- Tank truck couplings EN 14420-6

- Sandblast couplings

- EDBRO and DIN 74254

- Couplings for washing devices

- GEKA garden hose quick couplings

- GARDENA couplings

- Compressed air couplings

- Plastic quick connect couplings

- LinkTech couplings

- Banjo type fitting

- Press fitting

- Hose connector

- Flange screw joints

Storz couplings

Storz couplings are often used and designated as fire hose couplings. However, they have wide usage in many industries, including refineries, agricultural uses, construction industry, maritime safety, and military use due to their resistance against against a wide variety of media. These are non-shut-off symmetrical couplings connected by plugging the lug parts into each other and then twisting against each other. These can easily be coupled due to the rotatable lug parts while the seals are protected. Storz couplings are available in both brass and aluminum with various connection types like: hose pillar, female threads, male threads, reducer, flange, etc.

Storz Couplings have special designations:

- D-couplings (lug distance 31 mm)

- C-couplings (lug distance 66 mm)

- B-couplings (lug distance 89 mm)

- A-couplings (lug distance 133 mm)

Read our in-depth article on the uses and characteristics of Storz couplings to learn more about these versatile couplings.

Camlock couplings

Camlock couplings, sometimes referred to as cam and groove couplings, are lever arm type couplings that have been standardized worldwide according to MIL-C-27487 and EN 14420-7 (DIN 2828). As the coupling has no threads that can become dirty or fouled, the Camlock couplings are often used in moderately dirty environments. Examples of this are septic tank pump trucks, and chemical or fuel tanker trucks. The coupling plugs are pushed into the coupling socket and by adjusting the levers it properly seals against the replaceable flat seal. These couplings offer full throughway and can be used for both fluids and solids as they have no internal valves. Camlock couplings are available in various materials: stainless steel 316, polypropylene, brass, and aluminum. Seals are available in NBR and EPDM. They are supplied with safety cotter pins or are equipped with safety hand levers, which protect the levers against accidental decoupling. Various connection types are available, including: male threads, female threads, welded, hose pillar, etc.

Guillemin couplings

Guillemin couplings are widely used for tanker trucks, silos, and agriculture applications, especially in the Netherlands, Belgium, and Luxemburg. Guillemin couplings are used for pressure and suction delivery of liquids, powders, and granulates. They are symmetric couplings designed in compliance with NFE 29572 and EN 14420-8 and made out of stainless steel or aluminum. The connection for the Guillemin couplings is made by interlocking four vertical jaws. Usually, a coupling is used on mobile systems equipped with an adjustable clamping ring, which locks the jaws by twisting. To create a connection, at least one of the coupling halves must be equipped with a lock. Keep in mind that only the coupling with the lock is equipped with a soft seal, which can be made out either: FKM (fluoroelastomer), PTFE (Polytetrafluoroethylene), or NBR( Nitrile rubber).

Mold couplings

Mold couplings (Figure 1) are typically used for liquid media at temperatures up to +160°C. For example, they are used on cooling circuits of injection molding machines and die-casting equipment. They have various connection types: push-in coupling socket, hose barb, threaded, etc. and are available as straight, 90°, or 45°. There are also options of having a check valve inside the mold coupling. Due to the high temperature, they are made of either brass or stainless steel. The DN 6 couplings (9 mm spigot) are compatible with Hasco couplings of series Z8 and Z9.

Tank truck couplings EN 14420-6

Tank truck couplings, also referred to as TW couplings, are asymmetric couplings to connect hoses mainly for loading- and unloading tank trucks. Couplings used on tank trucks are standardized throughout Europe through the EN 14420-6 standardization. The couplings consist of a male and female part, which can be connected by turning the clamping lever and seal into the female parts crown. After turning, the clamping lever is locked into place, thus creating a secure connection.

Figure 2: Tank truck couplings

Sandblast couplings

These symmetrical, non-shut-off, 58 mm clamp width couplings connect sandblast hoses with mobile and stationary sandblasting equipment. The couplings can be secured by twisting the claws into each other. There is no difference between the plug and sleeve. Sandblast couplings are available as coupling with a hose connector, coupling with female thread, made out of malleable cast iron, or nylon. Some sandblast couplings have an improved sealing system, which ensures the hose or thread is positioned on the seal. With this, the blasting sand cannot be compressed behind the seal, which would cause blockages. In the case of all other couplings, the hose is separated from the seal with a ridge. Care should be taken when selecting the correct coupling as the 40mm garden couplings are very similar in looks.

Figure 3: Sandblast couplings

EDBRO and DIN 74254

Couplings that are constructed following the dimensions of EDBRO are commonly used in the automotive industry as economical hydraulic couplings. Dual circuit brake couplings from EDBRO are designed to meet the DIN 74254 international standard and can be combined with products from other manufacturers under the same standard. A distinction is made between couplings with and without valves. Couplings with valves are used on the tractors and prevent that after decoupling air leaks from the coupling. Couplings without valves are used on the trailer. Attaching EDBRO couplings is done by screwing the plug and the sleeve together. Sealing the valve chamber before the valves open is part of the coupling process. When uncoupling, the valves are already closed, before the connection can be pulled out of the seal. Different brake circuits are distinguished from each other through yellow or red cover caps.

Figure 4: EDBRO and DIN 74254

Couplings for washing devices

These couplings are designed for use on washing machines made by WAP, Kärcher, or Kränzle and are safe to use with water and cleaning agents. These couplings withstand strong vibrations and can be used for the connection of washing gun and hose or wash device and hose. We recommend the use of stainless steel couplings depending on the application. For foam application guns we offer special connecting couplings, which are used for connecting rinsing lances/foam lances with the foam application guns.

Figure 5: Washing device coupling

GEKA garden hose quick couplings

These symmetrical, non-shut-off couplings come with a 40mm claw distance and can be coupled by twisting the claws into each other. Brass and stainless steel garden hose couplings are ideal to couple garden hoses quickly and economically. There is no difference between plug or sleeve. These couplings do not have a shut-off function; before decoupling any hoses, you must check them for residual pressure. The dangers of decoupling under pressure are reduced with the use of a safety coupling. These will relieve the pressure before the claws are released. Garden hose quick couplings are available with various connections: female threaded, male threaded, hose screw connection, screw connections for industrial connections, quick couplings, and Gardena couplings, amongst others. Also, couplings with KTW approval are available.

GARDENA couplings

Gardena garden hose couplings are the standard for private and professional irrigation purposes and are typically made of brass or plastic. The couplings are coupled by inserting the plug into the coupling socket and decoupled by activating the coupling sockets loosening sleeve. Gardena offers a broad spectrum of fittings with this connection type, including: coupling plugs, coupling sockets, coupling distributors, spray guns, washing brushes, and watering devices.

Compressed air couplings

Our compressed air couplings, also known as air hose coupling, compressed air coupling, pneumatic coupling or compressor coupling, are available in a wide variety of designs, for a wide variety of uses. The quick-release system allows for simple and easy installation by hand, eliminating the need for tools. These couplings are used in all types of compressed air systems, and most commonly used in applications with pneumatic cylinders, tools, and equipment. The push-on connection method allows for rapid changing of components, so these are ideal if you have one air source for multiple tools that can be exchanged out. Tameson offers a wide variety of solutions for pneumatic systems, for more insights and to help you choose the correct couplings for your system, read our article about pneumatic couplings

Figure 6: Compressed air couplings

Plastic quick connect couplings

Plastic quick connect couplings of POM and PVDF are designed for use in the medical, chemical, food, pharmaceutical, and laboratory technology industries. The coupling system is designed for one-handed operation. The color-coding of the coupling and plug provides a guarantee of preventing mix-ups of media during coupling. The coupling is also available without a valve for a straight-through system. These couplings are suitable for systems operating with relatively low-pressure ranges, low mechanical loads, and media/environmental influences for which brass would not be a suitable option.

Figure 7: Plastic quick connect coupling

LinkTech couplings

Our LinkTech series of couplings is a unique series of couplings widely used in both the chemical industry and in medical technology. LinkTech is considered the world’s largest producer of interchangeable Quick Couplings - offering high-quality, general-purpose quick disconnect couplings. The couplings are made of POM, PP (polypropylene), polysulphone, or nickel-plated brass. These couplings are mainly used for liquids and gases with low pressure. The coupling sockets and plugs can be used either as shut-off or non-shut-off. For applications that require frequent coupling and decoupling, the use of plugs or couplings made out of metal is recommended. The materials and shut-off or non-shut-off coupling sockets and plugs can be mixed arbitrarily within one series.

Advantages of the LinkTech couplings include:

- Audible “click ensures a secure connection

- Intuitive thumb-latch design, one-hand disconnect

- Interchangeable with other thumb-latch type couplings

- Integral end terminations eliminate leak points

- Rotates while connected and pressurized

- Leak-free O-ring seal design

- Individual series connect together

Figure 8: LinkTech coupling

Banjo type fitting

A banjo fitting or internally relieved bolt is a special pipe fitting commonly used for hydraulic systems. They are also used in automotive fuel and oil systems. The male part of a banjo fitting consists of a hollow, cross-drilled bolt so fluid can flow up and out of the bolt. The female part consists of a round ring-like collector. Banjo fittings main advantage is that you can use them with high-pressure applications exceeding 50 bar. These fittings do not have to be rotated relative to the host fitting. The design minimizes the risk of damage by twisting the hose when screwing the fitting into place.

Below are some of the common types of Banjo fittings and bolts:

- T-banjo

- Banjo bolts 1-way

- Banjo bolts 2-way

- Banjo bolts 3-way

Figure 9: Banko type fitting

Press fittings

Press fittings of copper or stainless steel are used to connect pipes, such as compressed air distributions quickly. The fittings are available in pipe diameters 15-54 mm and can be pressed using conventional die sets (i.e. Mapress, Viega or SA). Copper fittings are compatible with any copper pipe produced according to EN 1057. Stainless steel fittings are compatible with any system pipe according to DIN EN 10312. Press fittings are especially suited to be used in compressed air systems. To enable this, all fitting have been fitted with FKM seals.

Some examples of compression fittings that are available:

- Transition sleeve nipple with pressing from the inside & male thread

- Reducing socket with interior press end

- Screw connection separatable, flat seal, both sides interior press end

Figure 10: Press fitting

Hose connectors

Hose connectors can be fastened with a hose clip or clamp, or hoses can be fitted to these connectors without the aid of a clip or clamp. The deciding factors are the systems operating pressure, the inside diameter of the hose, and the reset force of the hose. When the system uses soft hoses, high or dynamic pressure ranges, or even large temperature changes, a clip or clamped hose connection is recommended. Hose connectors are available in various materials, such as brass, stainless steel, steel, plastic, and aluminum.

There are various designs of hose connectors and all serve different purposes and include, amongst others:

- V / T / Y-push in connectors for PUR, PUN, and PA hoses

- Rotatable T-push on fittings for PU-, PUN- and PA hose

- Standard hose connection tubes

- Specialized hose connectors made for specific industries (i.e. medical)

Figure 11: Hose connector

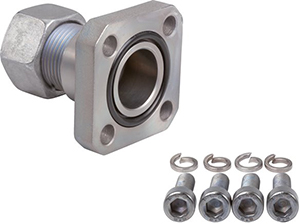

Flange screw Joints

Flange screw joints are typically used for use on hydraulic pumps or motors. Cutting ring screw connections, or female threads are used to join pipes or hoses. The pump, or motor, is clamped on the flange by means of screws, with an O-ring or sealing sleeve used for sealing. An important distinction is made between flange screw connections with a square hole pattern and flanges with SAE hole pattern 3000/6000 PSI made according to ISO 6162. With the square hole pattern the circle of the fastening hole is critical and comes in 35, 40, or 55 millimetres. SAE hole pattern flange screw connections are clamped with special SAE flange halves on the contact surface using screws.

Figure 12: Flange screw joints