Camlock Coupling Types

Figure 1: Camlock fitting type B made of polypropylene

Camlock fittings allow for a quick and convenient connection of hoses and pipes for transferring fluids and solids. They are ideal for applications requiring frequent hose changes, such as in the petroleum and trucking industries. Camlock fittings come in various types, like male/female threads or hose pillar ends, each designed for specific connection needs. They are also called cam and groove couplings. This article explores the different camlock types and how to choose one for an application.

View our online selection of camlock couplings!

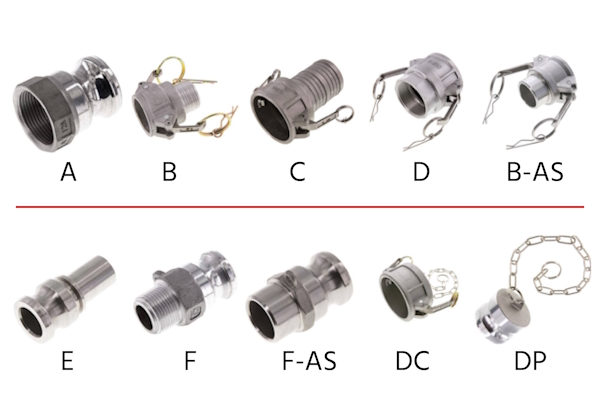

Camlock fitting types

Camlock fitting types are differentiated by their connection ends, such as male or female threads, hose tails, or weld connections.

- Type A: Male adapter with female threads. This type connects to a female coupler and a male-threaded pipe or fitting.

- Type B: Female coupler with male threads. It connects to a male adapter and a female-threaded pipe or fitting.

- Type B (AS): Female coupler with a weld connection, designed for permanent installations.

- Type C: Female coupler with a hose tail. It connects to a male adapter and a hose.

- Type D: Female coupler with female threads. This type connects to a male adapter and a male-threaded pipe or fitting.

- Type E: Male adapter with a hose tail. It connects to a female coupler and a hose.

- Type F: Male adapter with male threads. It connects to a female coupler and a female-threaded pipe or fitting.

- Type F (AS): Male adapter with a weld connection, designed for permanent installations.

- Type DA: Dust cap for male adapters. It covers and protects the male adapter when not in use.

- Type DC: Dust cap for female couplers. It covers and protects the female coupler when not in use.

- Type DP: Dust plug for female couplers. It is used to seal and protect the female coupler when not in use.

Figure 2: Different types of camlock fittings

How to select the correct camlock fitting

Selecting the appropriate camlock fitting is essential for a secure and efficient connection. Consider the following factors:

-

End connection type: Determine the type of connection required for the application:

- Hose connection: If connecting to a hose, select a camlock with a hose pillar end, such as Type C or E. These types are designed to fit snugly into hoses, providing a secure seal that prevents leaks.

- Male thread connection: Choose a camlock with a female thread, such as Type A or D, for connections to a male-threaded pipe or fitting.

- Female thread connection: If connecting to a female-threaded pipe or fitting, opt for a camlock with a male thread, such as Type B or F.

-

Size:

- Coupling size: Coupling size refers to the diameter of the camlock fitting itself. It is typically measured in inches and corresponds to the size of the hose or pipe that the camlock will connect to. Common sizes range from 1/2 inch to 5 inches.

- Size of threaded connection: The threaded connection size refers to the size of the threads on the camlock fitting, which connect to a threaded pipe or equipment. The threaded connection size is also measured in inches and should match the size of the threaded component you are connecting to. It is also essential to ensure compatibility with the thread type (e.g., NPT, BSP). Read our camlock fitting measurement article for more information on measuring camlock fittings.

-

Housing material: Ensure the camlock fitting material is compatible with the system's fluids. Typical housing materials are stainless steel, aluminum, brass, and polypropylene.

- Stainless steel: Stainless steel has excellent corrosion resistance.

- Brass: Ideal for applications involving water and petroleum products and where good corrosion resistance is required.

- Aluminum: Aluminum is lightweight and suitable for general-purpose applications.

- Polypropylene: Polypropylene is used in low-pressure applications where chemical resistance is essential.

-

Seal material: The common seal materials are NBR, Teflon, and EPDM.

- NBR: NBR is resistant to compression, tearing, and wear and is compatible with oil products, solvents, and alcohol. However, it is sensitive to weather influences and has moderate temperature resistance.

- Teflon: Teflon is resistant to almost all fluids but is not flexible.

- EPDM: EPDM is suitable for water, steam, ketones, alcohols, brake fluids, and acids/alkalis in low concentrations. It has excellent resistance to weather influences but poor resistance to oil, grease, and solvents.

-

Maximum pressure and temperature:

- The camlock fitting material should withstand the maximum pressure and temperature of the system it connects to. For example, stainless steel and brass camlocks can handle up to 18 bar (261 psi), while polypropylene works well up to 6 bar (87 psi).

- The seal material determines the maximum temperature tolerance, and the camlocks can typically handle up to 80 𐩑C (176 𐩑F).

FAQs

What is a camlock coupling used for?

A Camlock coupling quickly connects and disconnects a hose and pipe in a fluid transfer system commonly used in agriculture, manufacturing, and oil and gas.

What is the difference between Type A and Type B camlock?

Type A camlocks have a male adapter and female thread, connecting hoses to threaded pipes. Type B camlocks have a female cam and male thread, connecting threaded pipes to hoses.

What is a Type C camlock coupling?

Type C camlock features a female cam coupler and a hose barb designed to connect hoses to other hoses or pipes for easy attachment and detachment.