Burkert 6013 Solenoid Valve - How They Work

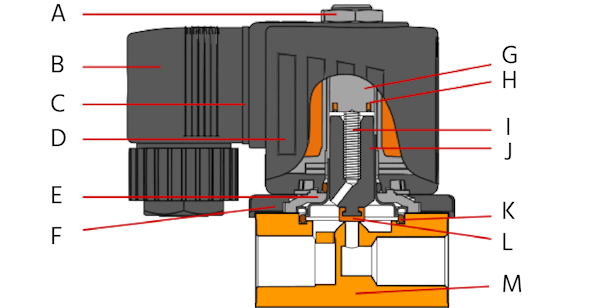

Figure 1: Bürkert Type 6013

The Bürkert valve 6013 is a compact, direct-operated 2/2-way solenoid valve available in NC and NO versions. It is cost-effective and suitable for neutral and clean liquids, gases, and vapors, with some models handling mildly acidic and alkaline solutions. Various body and seal materials, along with multiple certifications, make it versatile for different applications. Special versions are available for extreme temperatures, flammable gases, ATEX environments, low power needs, and fat & oil-free analysis equipment.

Table of contents

- Is Bürkert 6013 the right valve for you?

- Operating principle and design

- Approvals for the 6013 valve

- Features

Buy Bürkert 6013 Online

Is Bürkert 6013 the right valve for you?

Type 6013 is a general-purpose valve used for shut-off, filling, dosing and ventilation. The compact valve is suitable for small flow rates, the nominal diameter lies between 2 and 6 mm. The maximum pressure varies from 0.75 up to 25 bars, depending on the orifice size and coil. Because of the direct acting design, the valve can be used in systems without a pressure differential, such as a closed circulating circuit or gravity fed system. It can even be used for technical vacuum. The bolted-coil design is designed to withstand strong vibrations. Housing materials are brass or stainless steel (grade 303). The valve is available with an inline design with port sizes from G1/8” up to G3/8” or a subbase design suitable for manifold mounting (SFB). Type 6013 is an all-round valve, but it also features special versions for the following applications:

- Analysis version: the valve is completely oil, silicon and fat free. Media flowing through are not contaminated.

- Gas version (DVGW): for use in gas burning appliances as automatic shut-off valve.

- ATEX approved version: for use in potentially explosive atmospheres.

- Pulse coil version: very low power consumption. A short pulse of at least 50 ms opens the valve. A pulse with reversed polarity closes the valve. This principle also called latching or bi-stable.

- Kick and Drop’ electronics: An integrated circuit reduces the coil current after opening, leading to a significant power reduction.

- High and low temperatures version: for media temperatures between -40 and +180°C.

Operating principle and design

Bürkert Type 6013 comprises of two basic elements: the main valve body and the push-over coil. Figure 2 shows the main components.

Figure 2: Type 6013 components: locknut (A), cable plug (B), flat seal (C), coil (D), cover (E), sub-base (F), stopper (G), shading ring (H), spring (I), magnetic core (J), armature seal (K), seal (L), and valve body (M).

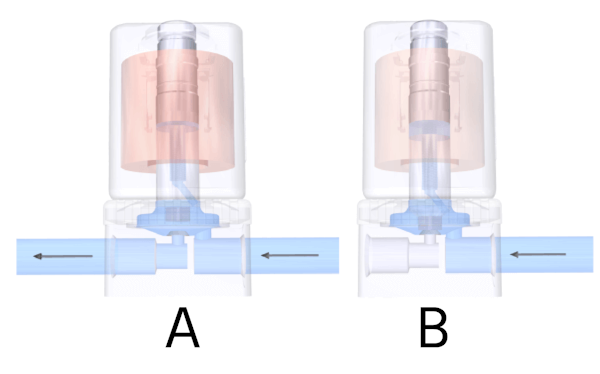

In a de-energised normally closed valve, the closing spring, supported by the pressure of the medium, presses the seal onto the valve seat. When the coil is energised, it generates a magnetic force that pulls the plunger in and against the return spring. The upward motion of the plunger lifts the seal up from the valve seat and opens the channel (Figure 3).

In this direct-operated solenoid valve, the stopper and plunger guide tube are welded together which provides for an enhances pressure resistance and leak-tightness.

All valves from the 6013 series have a vibration proof design. The coil is screwed with bolts directly to the valve body. Furthermore, the coil is fully encapsulated in epoxy to ensure high stability. The epoxy is also chemically resistant.

Figure 3: Type 6013 operating principle: energized (A) and de-energized states (B)

Approvals for the 6013 valve

The Burkert 6013 valve type is available with the below listed approvals:

- UL, UR: Underwriters Laboratories inspects and certifies products with respect to their safety

- CSA-EX DIV ½: The Canadian Standard Organization

- European gas approval: Class A, Group 2

- ATEX: ATEX covers devices and protective systems that will be used in explosion-prone areas (Europe)

- FM (NEMA): Division and Zone classifications for hazardous locations

Features

Material selection

The body materials available for this valve are brass and stainless steel (1.4305, or grade 303). The available seal materials FKM and PTFE/Graphite. EPDM can be provided on request.

Port size range

The valve is available with port sizes from G 1/8“ up to G 3/8“. Table 1 shows the corresponding orifice sizes and Kv-values. The Kv-value indicates the flow rate of water in m3 per hour with a pressure drop of 1 bar. Correct valve sizing is very important to guarantee good performance of your system and also to optimize costs. Please note that the maximum pressure of DC valves is lower than that of AC valves. Use our valve sizing calculator to quickly determine the right valve size.

Table 1: Orifice sizes and Kv values

| Port size (BSP) | Orifice (mm) | Kv (m3/h) | Pressure AC version(bar) |

| G 1/8" | 2.0 | 0.12 | 0-25 |

| G 1/8" | 2.5 | 0.16 | 0-16 |

| G 1/8" | 3.0 | 0.23 | 0-10 |

| G 1/4" | 2.0 | 0.12 | 0-25 |

| G 1/4" | 3.0 | 0.23 | 0-10 |

| G 1/4" | 4.0 | 0.30 | 0-4 |

| G 1/4" | 6.0 | 0.55 | 0-1.5 |

| G 3/8" | 3.0 | 0.23 | 0-14 |

| G 3/8" | 4.0 | 0.30 | 0-6 |

| G 3/8" | 6.0 | 0.55 | 0-2.5 |

Analysis version (6013 A)

Type 6013 A is a high-quality solenoid valve manufactured for analysis and vacuum technology. The valve is manufactured under clean-room conditions and undergoes tightness tests. No oils, fats or silicone is used during the assembly, and all media-affected parts are submitted to additional purification processes, so that the media is not contaminated under any circumstances.

Electric power reduction (kick and drop electronics)

The Bürkert 6013 is available with an integrated power reduction feature called ‘Kick and Drop’ electronics. Right after the valve opens, the electric power is reduced far enough that the valve remains open.

Pulse coil (latching)

The pulse coil versions provide a solution for applications with low frequency switching. In a pulse coil, a short electrical pulse initiates the switching by energizing the solenoid core. Then an integrated permanent magnet holds the plunger in place. A pulse with revered polarity creates an opposed force that releases the plunger. Since no electrical power is required to hold the switch position, power consumption and heat development in the valve remain low.

Explosion protection - ATEX versions

For potentially explosive environments, explosion proof versions of this valve are available. The ATEX version of Bürkert type 6013 is for use in Zone 1 or Zone 2. In this version of the valve, the coil is encapsulated and its cable is moulded.

The available ATEX ratings for coils with fixed cable outlet are:

- II 2G Ex mb IIC T4 Gb

- II 2D Ex mb IIIC T135°C Db

While the ATEX ratings for the assembly of the coil and the junction box are:

- II 2G Ex eb mb IIC T4 Gb

- II 2D Ex mb tb IIIC T130°C Db

Body design: inline or subbase (SFB)

The valve is available with threaded ports or with a subbase design. The Bürkert specific flange design (SFB) enables valve to be mounted as a block directly on a multiple manifold to save space.

Manual override

Optional manual actuation provides for easy maintenance and commissioning.

Abrasion protection

To reduce mechanical abrasion in use with dry gases, PTFE sliding rings prevent metallic abrasion between core and core guide tube which increases the service life and stability of the valve.