Burkert 0330 Solenoid Valve - How They Work

Figure 1: Burkert 0330 solenoid valve

The Burkert solenoid valve type 0330 is a direct-operated, media-separated valve that isolates fluid from its working parts. This makes it ideal for aggressive or slightly contaminated media. The valve can be 2/2 or 3/2-way, normally closed or normally open, and is suited for mixing, distribution, diversion, and universal media direction. Due to minimal wear and few moving parts, it offers a long service life. The valve is particularly popular in water and gas analysis, the pharmaceutical industry, and food processing.

Is Burkert 0330 the right valve for you?

The Burkert type 0330 solenoid valve is ideal for aggressive, slightly contaminated media with relatively low flow rates. Since it is direct-operated, no minimum differential pressure is required. Therefore, it works well in a closed circuit or a gravity-fed system.

The Burkert 0330 valve may be an optimal selection for your application under the following conditions:

- The media is aggressive with slightly contaminated substances.

- The application requires a relatively low flow rate, as the valve has internal orifices ranging from 2 to 5 mm.

- The valve is intended for use in environments with potential explosive hazards.

- The application necessitates a valve suitable for handling drinking water or oxygen as the medium.

- A valve with an extended service life, low power consumption, and minimal maintenance needs is desired.

Figure 2: Burkert Type 0330 explosion proof version

Operating principle and design

The Burkert 0330 valve is a media-separated direct-operated pivoted armature solenoid valve.

2/2-way

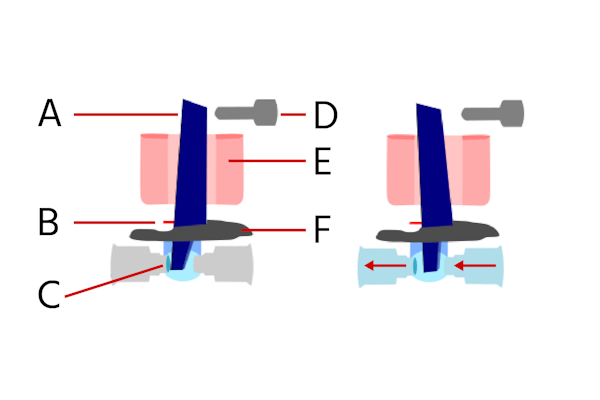

In a normally closed 2/2-way (NC) valve (Figure 3), the plunger is an armature (Figure 3 labeled A) that pivots when the core is energized. This armature passes through a flexible diaphragm (Figure 3 labeled F) and enters the valve body. The diaphragm isolates the pivot (Figure 3 labeled B) from the media. In the absence of power, the armature is pressed against the valve seat (Figure 3 labeled C), preventing flow. Upon energization, the armature pivots, allowing the flow to commence.

Conversely, in a normally open (NO) valve, the media is free to flow when no power is applied. When power is supplied, the armature pivots upward against the valve seat, preventing flow.

Figure 3: Burkert 0330 2/2-way normally closed solenoid valve operation showing de-energized (left) and energized (right) states: pivoted armature (A), pivot (B), valve seat (C), manual override (D), coil (E), and isolating diaphragm (F).

3/2-way

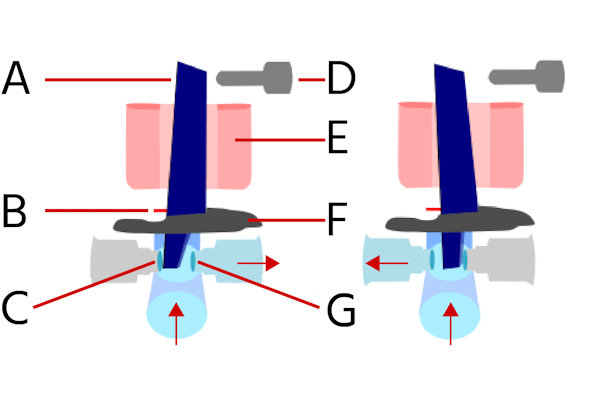

The same operational principle applies to the 3/2-way distribution version of this valve type (Figure 4).

In the de-energized state, a return spring holds the armature (Figure 4 labeled A) against valve seat 1 (Figure 4 labeled C). In this configuration, the medium flows through the outlet on the right, corresponding to valve seat 2 port (Figure 4 labeled G).

When the coil is energized, the armature moves away from seat 1 and presses against seat 2. This action redirects the medium flow to the outlet on the left, corresponding to valve seat 1 port.

Figure 4: Burkert 0330 3/2-way distribution solenoid valve operation showing de-energized (left) and energized (right) states: core, pivoted armature (A), pivot (B), valve seat 1 (C), manual override (D), coil (E), isolating diaphragm (F), and valve seat 2 (G).

Features

Circuit functions

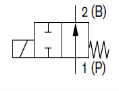

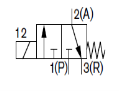

Burkert type 0330 is available in various circuit functions to satisfy the requirements of the application.

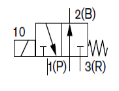

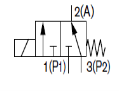

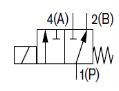

Table 1: Main circuit functions of Burkert Type 0330 solenoid valve

| Circuit function | Image |

| 2/2 way direct-acting solenoid valve, normally closed |

|

| 2/2 way direct-acting solenoid valve, normally open |

|

| 3/2 way direct-acting solenoid valve, normally closed |

|

| 3/2 way direct-acting solenoid valve, normally open |

|

| 3/2 way mixing solenoid valve |

|

| 3/2 way direct-acting, distribution solenoid valve |

|

| 3/2 way direct-acting solenoid valve, flow direction optional |

|

Port size, flow rate, and voltage

- The valve is available with a port connection of ⅛ or ¼ inches (3.2mm or 6.3mm).

- Kv values from 0.08 to 0.4 m3/h are available.

- The Kv values and pressure ratings depend on the housing material and circuit function. Use the datasheet for a complete overview of selecting the valve based on the different nominal diameters, flow coefficients, and operating pressure ranges for standard and vacuum conditions.

- Both AC (24V, 42V, 48V, 110V) and DC (12V, 24V, 36V, 48V, 60V, and 110V) versions are available.

Material selection

The Type 0330 solenoid valves have housings constructed from brass, stainless steel (1.4401), and plastic. Additionally, a range of seal materials is offered to accommodate diverse media applications:

- NBR: Neutral mediums such as compressed air, town gas, water, hydraulic oil, oils, fats without additives, and oxygen. Suitable for medium temperature up to 80 𐩑C (176 𐩑F).

- EPDM: Alkalis, acids to medium concentrations, alkaline washing and bleaching lyes. Suitable for temperatures up to 80 𐩑C (176 𐩑F).

- FKM: Oxidizing acids and substances, hot oils with additives, salt solutions, waste gasses, and oxygen. Suitable for medium temperatures 0 to 90 𐩑C (32 to 194 𐩑F)

- FFKM: Aggressive mediums, hot air, hot oils. Suitable for medium temperature up to 90 𐩑C (194 𐩑F).

Read our chemical resistance page for more details on the compatibility of various housing and seal materials with different media.

Additional features

-

Electric power reduction: The Burkert 0330 valve offers two unique coil power reduction designs: the impulse (latching) version and electronic power reduction (5W), both of which are available upon request.

- The impulse version is bi-stable, requiring only a 150ms pulse to change position. It has two independently wound coils. This design minimizes power consumption and heat, making it ideal for mobile systems with long open/close periods.

- The electronic power reduction version uses a component in the connector to switch from inrush to holding power, which is suitable for lower pressure ranges.

- For vacuum: The vacuum version is engineered to handle vacuums up to -0.98 bar, ensuring reliable performance in applications that require low-pressure operation.

- Position feedback: Position feedback provides real-time status updates of the valve's position through electrical or optical signals, configurable as binary or NAMUR signals, for improved monitoring and control.

- Analysis version: The analysis version meets stringent hermetic and purity standards. Units are tested for leak tightness at 10- 2 mbar x l/sec, and options for oil, grease, and silicone-free configurations ensure high purity and cleanliness.

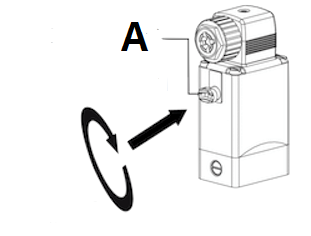

- Manual override: Burkert 0330 is equipped with a lockable manual override for better safety and convenience during commissioning, testing, and maintenance (Figure 5 labeled A). When the manual control is locked, the valve cannot be electronically actuated. Press and turn the manual control button (A) to operate the valve manually.

Other features, such as Class H coil insulation for high-temperature durability, a silicon-free design for contamination-sensitive applications, and compatibility with oxygen service, are also available.

Figure 5: Manual override in Burkert Type 0330

Approvals

This valve type is available with the listed approvals:

- CE ATEX: Certified for use in explosion-prone areas in Europe

- EAC: Approved for markets in Russia, Kazakhstan, and Belarus

- IECEx: Suitable for explosive environments with flammable substances

- UL, UR: Certified for safety by Underwriters Laboratories

- FM: Approved for hazardous locations with specific classifications

- CSA: Meets Canadian safety and performance standards

- DNV-GL: Certified for maritime and offshore industry standards

- NSF/ANSI 61: Approved for drinking water systems in North America

- FDA: Compliant with U.S. standards for food and pharmaceuticals

Figure 6: Burkert 0330 solenoid valve approvals list