How to Choose the Correct Ball Valve for Sandblasting

Figure 1: Sandblasting equipment showing ball valves at the outlet of the blast pot

Ball valves control the flow of air/water and abrasive media in sandblasting systems. Sandblasting uses high-speed sand (or other abrasive materials like crushed glass or plastic) to clean or remove paint from a surface. The process can be air or water-driven. Ball valves for sandblasters should withstand high pressures and abrasive environments, ensuring precise regulation of media flow and system pressure. This article explores the role of ball valves in sandblasting, focusing on their design, material selection, and operational considerations.

Table of contents

- Sandblaster ball valve

- Sandblasting valve type

- Material compatibility

- Pressure ratings

- Effect of humidity

- Valve size

- FAQs

View our online selection of ball valves!

Sandblaster ball valve

In sandblasting equipment, a ball valve primarily provides on/off control for the flow of fluids, such as compressed air or water.

- Air supply control: Ball valves control compressed air flow from the air compressor to the blast pot. They allow operators to quickly start or stop the air supply, which is essential for controlling the operation of the sandblaster.

- Water control in wet blasting: Ball valves manage the water flow in wet or vapor blasting systems. They allow precise control over the water supply, which is mixed with the abrasive media to reduce dust and improve surface finish.

- System isolation: Ball valves serve as isolation valves, enabling sections of the sandblasting system to be shut off for maintenance, safety, or operational adjustments without affecting the entire system.

- Abrasive mixing control: Ball valves at the blast pot outlet regulate the flow of abrasive media into the air or water stream. This allows adjustments to optimize blasting performance and stop media flow when necessary. It's important to fully open or close the valve to prevent erosion, as partially open positions can concentrate abrasive flow and damage softer materials like brass. While ball valves are used, metering or pinch valves are often preferred for their precision in controlling abrasive media flow.

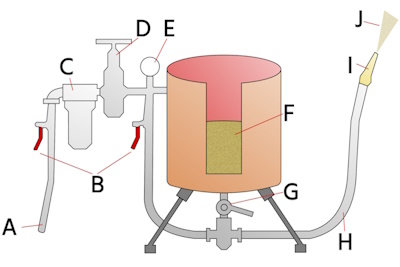

Figure 2: Dry sandblasting setup diagram: Incoming air from compressor (A), ball valve (B), water separator (C), pressure regulator (D), pressure gauge (E), abrasive under pressure (F), mixing valve (G), air and abrasive under pressure (H), nozzle (I), and blast (J)

Sandblasting valve type

2-way full-port manual ball valves are commonly used in sandblasting systems for their simplicity and reliability.

- Manual operation allows quick and easy control of air/water and abrasive media flow, essential for safety and efficiency.

- The 2-way configuration provides simple on/off with tight sealing.

- The full port design minimizes turbulence and wear by allowing the abrasive media to flow through with minimal restriction.

Material compatibility

-

Body material: Choose a valve body material compatible with compressed air/water, depending on the type of sand blasting. Materials like brass, stainless steel, and carbon steel are standard for air and water.

- Stainless steel is often preferred for its corrosion resistance and durability. Brass is more suitable for general-purpose use and is less costly.

- Seal material: The seals or seats should be made from materials like PTFE (Teflon) for their chemical resistance and low friction properties.

Pressure ratings

For most dry sandblasting applications, the air compressor used a typical pressure range of 6.2 to 6.9 bar (60 - 90 psi). This range is effective for general surface cleaning and coating removal. However, wet sandblasting systems operate at various pressures, ranging from 138 to 517 bar (2,000 to 7,500 psi).

Air is less dense than water, requiring less pressure to achieve the same particle velocity. Therefore, dry sandblasting systems operate at lower pressures than their wet counterparts. Always select a ball valve that can handle the maximum fluid pressure of the system.

Effect of humidity

Humidity introduces moisture into sandblasting systems. Moisture can lead to corrosion in ball valves, especially if not made from corrosion-resistant materials. It can also degrade seals, causing leaks, and lead to clumping of abrasive media, resulting in blockages and increased wear on the valve. To address these challenges:

- Use ball valves made from corrosion-resistant materials like stainless steel or brass.

- Install water separators or air dryers upstream of the ball valve to reduce moisture entry into the blast pot.

Valve size

The valve size should be compatible with the nozzle and hose used in the sandblasting system. Standard sizes range from 1/4 inch to several inches in diameter.

Figure 3: Sandblasting process