Using Ball Valves for Drinking Water

Figure 1: Brass ball valve with a drinking water certification

Ball valves are commonly used in residential and commercial drinking water systems. It's crucial to ensure the water quality from the point it enters the building. Strict standards govern the materials used in piping equipment to prevent contamination and bacterial growth.

When selecting a ball valve for drinking water, it is essential to choose one that is corrosion-resistant, chemically inert, and anti-legionella. The valve should be maintenance-free, provide a complete shut-off, be compact, and user-friendly. Compliance with relevant certifications and regulations is mandatory for all components in contact with drinking water. This article explores ball valves suitable for such applications.

Table of contents

Ball valves for drinking water

What is a ball valve?

A ball valve is a quarter-turn valve type. This means a 90 degrees turn will move the valve from the fully closed position to the fully open position. The valve consists of a ball with a hollow center where water passes through, as seen in Figure 2. Ball valves are popular in domestic and industrial applications. They are low cost, available with a wide variety of end connection types and maintain a consistent performance after several years of use. They can operate over a wide range of pressure and temperature, easy to install and replace, and can function for a long period without maintenance.

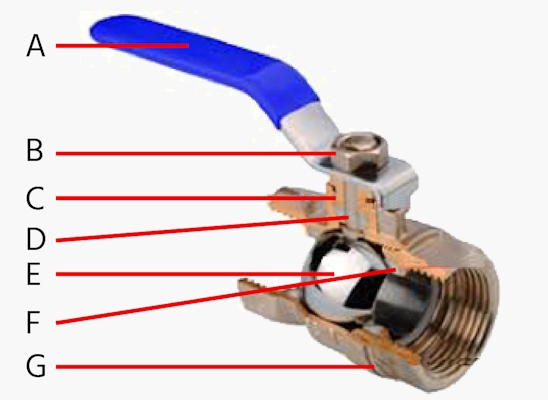

Figure 2: Components of a ball valve: handle (A), handle screw/bolt (B), shaft seal (C), shaft (D), ball (E), seal (F), and body (G).

Drinking water valve requirements

In domestic water distribution systems, the valves are often permanently installed. Over time, a water valve can degrade causing potential contamination and enabling microbial growth. Therefore, it is important to select a valve type that meets several requirements for drinking water. A good practice is to check the manufacturer’s documentation for compliance of the valve for drinking water applications. For more information on drinking water requirements, you can also read our drinking water article.

Depending on the country, there are different certifications and regulations required for valves that come in contact with drinking water. Some of these are:

Kiwa Water Mark

The Kiwa Water Mark is a Dutch certification for products that come in contact with drinking water. It covers both private and public water system requirements.

NSF (National Sanitation Foundation) – North America

The NSF is a North American product testing, inspection and certification organization. Components such as plumbing, water treatment chemicals and all other equipment that come in contact with drinking water are certified by the NSF Water Division.

WRAS (Water Regulations Advisory Scheme) – Great Britain

The WRAS certification affirms that a component such as water fittings, plumbing systems and equipment supplied with water from the public water supply, complies with the standard set out by the water regulations in the United Kingdom.

DVGW-W270 – Germany

The DVGW-W270 is a guideline and certification for the drinking water sector in Germany. It includes a test, according to the W270 worksheet, that checks bacteriological growth in a drinking water component.

ACS (Attestation De Conformite Sanitaire) – France

ACS is a mandatory approval in France for materials of equipment that come in contact with drinking water for human consumption.

WaterMark – Australia and New Zealand

The WaterMark is a mandatory certification scheme in Australia and New Zealand for plumbing and drainage products that come in contact with drinking water.

Figure 3: Drinking water certifications

Main drinking water valve features

Buying a valve with approvals is more expensive than one without, so ensure you require one with approvals. Apart from the listed certifications, drinking water ball valves will generally have the following features:

-

Material: It is important for the housing and seal material to not corrode, are resistant to wear, and do not affect the properties of the drinking water.

- Housing: The housing is typically made from brass. Brass does not affect the properties of drinking water. Brass ball valves offer superior resistance to contaminated media and ensure reliable sealing even in the presence of impurities. They are capable of withstanding high pressure, high temperatures, and high flow rates.

- Seals: The seals are typically made from NBR or EPDM, while the seats are made out of teflon.

Read our chemical resistance guide for more details on the compatibility of different materials with various media.

- Anti-legionella: For standard ball valves, there is a dead space around the ball that is created when the line pressure pushes the ball against the rear seat ring. This results in a good seal, but allows fluid to go between the front seal and the ball into the dead space. This can become stagnant water encouraging the growth of bacteria. For an anti-legionella ball valve, an extra hole exists to drain water around the ball.

- 2-way/3-way: Choose a 2-way ball valve for straightforward on/off control in drinking water systems, ensuring it meets material standards for safety and reliability. Opt for a 3-way ball valve when flow diversion or mixing is needed, considering the specific port configuration (T-port or L-port) to match your system's requirements.

- Flow rate: Ensure the ball valve can handle the required flow rate without causing excessive pressure drop or turbulence. Always choose a valve with a slightly higher flow rate than the required value. Read our Kv calculator for more details on how to size ball valves based on the flow rate.

- Connection size: Choose a connection size that aligns with the existing pipe dimensions to maintain system integrity and prevent leaks. Ball valves with 1/4 inches to 2 inches (6.3 - 51 mm) are typically available.

- Connection type: Drinking water ball valves are typically threaded (BSP).

- Pressure and temperature: The drinking water ball valves can handle upto 50 bar (725 psi) and 150°C (302°F).

- Bore size: Full port ball valves have a hole the size of the pipe diameter. This means the valve creates no resistance to the water flow.

- Handle: The handle can be a hand lever or a wheel and made from plastic or steel. The hand lever can be moved 90° to turn the valve ON/OFF. The hand wheel is scaled thus the angular position is reproducible.

To learn more about making the right selection of ball valves for your application, read our ball valve selection article.