Thread Sizes Standards

Figure 1: Valve threads

Thread standards are established to ensure compatibility and facilitate maintenance. They can be based on metric or imperial measurement systems. Determining the correct thread type for existing and new applications is essential to ensure a proper joint connection. However, there are numerous thread standards worldwide, and this article aims to discuss the primary types and their differences.

Table of contents

- How to identify an unknown thread type?

- Common thread standards

- Other thread standards

- Thread compatibility

Explore Tameson's selection of thread cutting tools!

How to identify an unknown thread type?

There are a few parameters to consider to identify an unknown thread:

- Gender: Male or female

- Taper: Parallel or tapered

- Thread diameter

- Thread pitch

Read our article on identifying unknown thread types for a detailed analysis of these parameters. The next step is to take this information and examine the common thread types and their details summarized below to find the correct thread type.

Common thread standards

BSP – British Standard Pipe

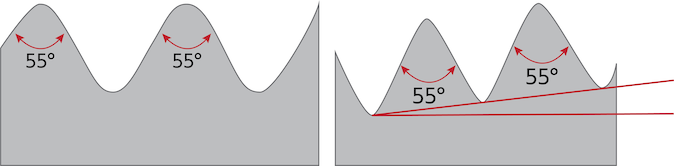

The BSP, or Whitworth thread, is a family of thread standards used internationally, except in the United States. This thread form has a 55° V-thread with rounded roots and crests, as seen in Figure 2. For a thread that conforms to BSP, the major diameter of the pipe thread is slightly smaller than the actual outer diameter of the pipe, and the minor diameter will be very close to, but smaller than, the inside diameter of the female thread. There are two types of BSP threads: BSPP and BSPT

Figure 2: A BSPP male parallel thread profile (left) and a BSPT tapered male thread profile (right)BSP-thread

NP – National (American) Pipe Thread

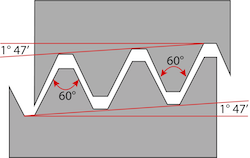

The American national pipe thread was created based on a 60° V-thread with flattened peaks and valleys (Figure 3) and is widely used in the United States and Canada. There are two types of NP threads: NPS and NPT.

Figure 3: NPT thread profile mating. The top is an internal pipe thread and the bottom is external.

Unified thread standards

In the United States and Canada, the Unified Thread Standard (UTS) describes a standard thread form and series, as well as the allowances, tolerances, and designations applied to screw threads. Bolts, nuts, and other threaded fasteners are standardized according to this standard.

Figure 4: Example of fine (left) and coarse (right) UTS threads

Other thread standards

JIS tapered pipe thread type (PT)

The JIS thread type is identical and interchangeable with the BSPT thread type. However, the male PT thread does not have a 30-degree flare, so it will not mate with the BSPP female swivel with a conical seat. Also, ensure to use a thread sealant with PT threads for a leakproof seal.

SAE thread type

SAE (Society of Automotive Engineers) has a set of straight threads having a 90-durometer Buna-N o- ring that aids in sealing. While many thread types require the female and male threads to crush against each other to form the seal, the o-ring in the SAE thread type prevents this and also ensures a leakproof seal.

Thread compatibility

Thread compatibility is important to avoid inefficient connections and potential danger. Although some BSP and NPT threads might tighten and engage reasonably well, pitch and thread angle differences between them can cause spiral leakage. At 1/16, 1/8, ¼, and 3/8 sizes, pitch difference results in misalignment of the threads. This misalignment might result in the threads partially fastening. However, at 1/2 and 3/4 sizes, NPT and BSP have the same pitch, which will allow them to engage well. There will still be issues with this connection because there are differences in thread forms and thread angles. If an appropriate thread sealant is used for low-end applications, these threads can be used together effectively. Read our thread compatibility article to learn more about this subject.