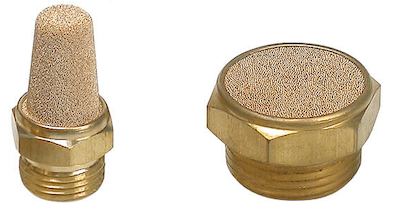

Pneumatic Silencer

Figure 1: Pneumatic silencer examples

A pneumatic muffler is utilized to release pressurized air into the atmosphere. It offers an economical and straightforward method to lower noise levels and prevent the discharge of contaminants from pneumatic systems. Often referred to as pneumatic silencers, these devices are typically installed on pneumatic 5/2-way solenoid valves, pneumatic cylinders, or fittings. This article delves into the design, specifications, and various types of pneumatic silencers for different applications.

Table of contents

View our online selection of pneumatic filters and mufflers!

How do pneumatic silencers work?

A pneumatic silencer's primary function is to vent pressurized air after it has performed work, ensuring a safe noise level. They can also prevent contaminants, such as oil, from exiting the system if combined with a filter. Excessive noise may be produced as the pressurized air is released into the environment. This noise results from turbulent air, which occurs when the fast-moving air from the vent collides with the static air of the environment.

The design of a pneumatic muffler typically includes the following components:

- Housing: The outer shell of the muffler is made from materials like metal (brass, stainless steel) or durable plastic. The housing encases the internal components and provides structural integrity.

- Porous material: Inside the housing, there is a porous material or mesh. This material is often made from sintered bronze, stainless steel, or plastic. The porous material has numerous tiny passages that allow air to pass through while diffusing and dampening the sound. Pneumatic exhaust mufflers are commonly designed with this porous material to increase the surface area of the exhaust port they cover.

- End connection: The muffler has a threaded, push-in, barbed, or snap-on connection that allows it to be easily screwed into the exhaust port of the pneumatic device. Additionally, they can be installed on hoses.

Here’s how it works:

- Exhaust air entry: When the pneumatic device operates, compressed air is expelled through the exhaust port. The muffler is connected to this exhaust port.

- Air diffusion: As the air enters the muffler, it passes through the porous material. The numerous small passages in the material break up the air flow into smaller streams. Silencers are installed directly at the exhaust port of a valve, diffusing the released air through a larger surface area, reducing turbulence and thus decreasing noise levels.

- Sound attenuation: The porous material absorbs and dissipates the energy of the air flow, significantly reducing the noise level. The sound waves are scattered and their intensity is diminished as they pass through the material.

- Air exit: The now quieter air exits the muffler and is released into the atmosphere.

A pneumatic muffler throttle valve combines a muffler and throttle valve to control airflow, vent pressurized air, and reduce exhaust noise in a single unit.

Figure 2: Silencer exhaust cleaner contains a filter to remove oil mist and dust in the exhaust air from entering the environment

Design

Air mufflers are designed in various shapes depending on the application.

- Cone-shaped: Cone pneumatic mufflers have a tapered design that aids in gradual pressure release, often resulting in better noise attenuation compared to flat mufflers. They are made from materials such as sintered bronze, stainless steel, or plastic. These mufflers are ideal for applications with higher flow rates and environments where gradual pressure release is beneficial.

- Flat-shaped: Flat pneumatic mufflers are characterized by their compact and low-profile design, making them ideal for applications with space constraints. They are typically made from sintered bronze or plastic and are suitable for low to medium flow rates, providing moderate noise reduction.

- Cylindrical: Cylindrical pneumatic mufflers offer a larger surface area due to their cylindrical shape, providing the best noise reduction among the three types. They come in various lengths and diameters and are made from sintered bronze, stainless steel, or plastic. These mufflers are suitable for high flow rate applications and are the best choice when maximum noise attenuation is required, provided that space is not a primary concern.

Figure 3: Cone(left), flat (middle), and cylindrical (right) air silencers

Specifications

Material

Selecting the appropriate materials for the housing, connection, and sound absorber components of a pneumatic muffler is essential for ensuring optimal performance and durability.

Housing materials

Housing materials refer to the materials used to construct the outer shell or body of the pneumatic muffler. The housing material must be durable and capable of withstanding the operating conditions of the pneumatic system.

Table 1: Pneumatic muffler housing materials

| Material | Temperature tolerance | Pressure rating | Features | When to use |

| Bronze | -40°C to 200°C | Up to 10 bar | Durable, corrosion-resistant | High durability and corrosion resistance needed |

| PE | -50°C to 80°C | Up to 6 bar | Lightweight, chemical-resistant | Cost-effective, lightweight applications |

| Plastic | Varies by type | Varies by type | Lightweight, cost-effective | General-purpose, less demanding environments |

| PBT | -40°C to 150°C | Up to 10 bar | High strength, chemical-resistant | High strength and chemical resistance needed |

Connection materials

Connection materials are the materials used for the part of the muffler that interfaces with the pneumatic system, typically the threaded portion that screws into the exhaust port of a valve, cylinder, or other pneumatic component. The connection material must be strong enough to handle the mechanical stresses of installation and operation, and it should be compatible with the materials of the components it connects to, to avoid issues like galvanic corrosion.

Table 2: Pneumatic muffler connection materials

| Material | Temperature tolerance | Pressure rating | Features | When to use |

| POM | -40°C to 100°C | Up to 10 bar | High stiffness, low friction | High dimensional stability needed |

| PA (Nylon) | -40°C to 120°C | Up to 10 bar | High strength, wear-resistant | High strength and flexibility needed |

| Aluminum | -50°C to 150°C | Up to 10 bar | Lightweight, corrosion-resistant | Weight is a concern |

| PE | -50°C to 80°C | Up to 6 bar | Lightweight, chemical-resistant | Cost-effective, lightweight applications |

| Plastic | Varies by type | Varies by type | Lightweight, cost-effective | General-purpose, less demanding environments |

| Brass | -40°C to 200°C | Up to 10 bar | Durable, corrosion-resistant | High durability and corrosion resistance needed |

| Stainless Steel | -200°C to 800°C | Up to 20 bar | High strength, corrosion-resistant | Extreme temperatures and harsh environments |

| Sintered Bronze | -40°C to 200°C | Up to 10 bar | Durable, noise-reducing | High mechanical strength and noise reduction needed |

| Nickel-plated brass | -40°C to 200°C | Up to 10 bar | Enhanced corrosion resistance | Enhanced durability and corrosion resistance needed |

Note: There are many different types of polymers available, each with its own unique properties. When selecting a polymer material for a pneumatic muffler, consider the specific requirements of your application, such as temperature tolerance, pressure rating, and environmental conditions.

Sound absorber materials

Sound absorber materials (or filter materials) are the internal components of the pneumatic muffler that directly interact with the exhaust air to reduce noise. These materials are typically porous, allowing air to flow through while breaking up sound waves and reducing their intensity. The sound absorber material is crucial for the muffler's primary function of noise reduction.

Table 3: Pneumatic muffler sound absorber materials

| Material | Temperature tolerance | Pressure rating | Features | When to use |

| Bronze | -40°C to 200°C | Up to 10 bar | Durable, corrosion-resistant | High durability and corrosion resistance needed |

| PA (Nylon) | -40°C to 120°C | Up to 10 bar | High strength, wear-resistant | High strength and flexibility needed |

| Aluminum | -50°C to 150°C | Up to 10 bar | Lightweight, corrosion-resistant | Weight is a concern |

| PE | -50°C to 80°C | Up to 6 bar | Lightweight, chemical-resistant | Cost-effective, lightweight applications |

| Stainless Steel | -200°C to 800°C | Up to 20 bar | High strength, corrosion-resistant | Extreme temperatures and harsh environments |

| Sintered Bronze | -40°C to 200°C | Up to 10 bar | Durable, noise-reducing | High mechanical strength and noise reduction needed |

| PUR Foam | -40°C to 80°C | Up to 6 bar | Excellent sound absorption | High noise reduction needed |

Connection type

Pneumatic silencers are connected to ports using a threaded male end. The port could be on a pneumatic solenoid valve (such as a 5/2-way valve), a pneumatic cylinder, or other fittings. Common thread standards used include NPT (National American Pipe Thread), BSP (British Standard Pipe), and metric (ISO standards). Also, using a push-in silencer allows for easy connection from one device or hose to another.

Figure 4: Pneumatic silencer symbol

Read our article on pneumatic mufflers for different applications for more details on pneumatic mufflers with specific functions.

Industry standards

To protect workers from exposure to harmful noise and toxic substances levels, organizations and governments define standards for machine manufacturers. Pneumatic silencers are commonly certified to the following standards:

- Pressure Equipment Directive (PED) - 2014/68/EC

- Restriction of Hazardous Substances (RoHs) - 2002/95/EC

- Registration, Evaluation, Authorization and Restriction of Chemicals (REACH) - EC No 1907/2006

- Occupational Health and Environmental Control - 1910.95(b)

Applications

Pneumatic silencers are essential in high-frequency pneumatic applications to reduce significant noise. Common applications include:

- Robotics: Robotics frequently use pneumatics to control movement or perform work on a load. For example, a robotic arm uses pneumatics to control its motion. Switching pneumatic valves on or off controls the arm's movement. Since robotics are often used alongside workers, controlling exhaust noise is crucial.

- Packaging: Pneumatics are often used in packaging machines to drive motion. A sorting machine, for instance, diverts products based on signals from an industrial controller, which activates a pneumatic device. Given the high operational rate and the large number of workers typically around these machines, pneumatic silencers are well-suited for packaging applications.

- Fence production machinery: Machines that produce rolls of fence often include pneumatic cylinders to cut fencing as it is woven into rolls. Operators work constantly alongside these machines to ensure the rolls meet specifications. To protect operators from damaging noise, pneumatic silencers are an ideal solution to reduce noise from the continuously operated machinery.

Read our Festo pneumatic muffler article for more information on the various types of pneumatic mufflers and throttle valves from Festo.

FAQs

What is the difference between a silencer and a muffler?

A pneumatic silencer and muffler are the same device and can be used interchangeably.

Will I ever need to clean my silencer?

Yes, routinely clean the threads and housing exterior to prevent blockages and reduce downtime, especially in polluted environments.

How can I ensure my silencer remains tight?

Apply a sealant to the silencer's thread to keep it tight during operation, based on the application's frequency and pressure requirements.