Types Of Bearings

Figure 1: Ball and roller bearings are the two main types of bearings.

Bearings are key parts in many machines, helping them run smoothly by lessening friction between moving parts. There are many kinds of bearings, each made to deal with different load conditions. This article focuses on two main types: ball bearings and roller bearings. It explains their different designs, compares them, and advises on how to choose between them.

View our online selection of bearings!

Ball bearings

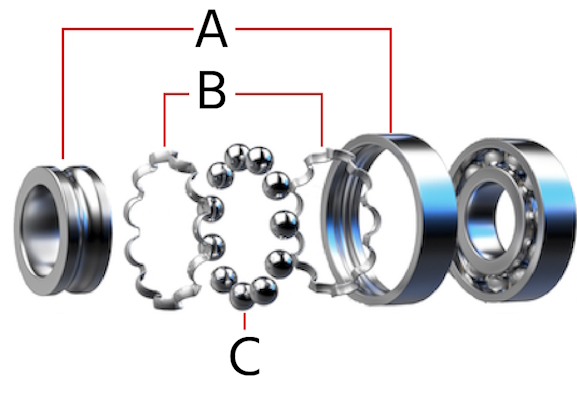

Ball bearings use spherical rolling elements to separate the bearing races. They use the balls' rolling motion to bear axial and radial loads. The major components of a ball bearing include an inner race (Figure 3 labeled A, left), outer race (Figure 3 labeled A, right), balls (Figure 3 labeled C), and a cage (Figure 3 labeled B) that prevents the balls from touching each other. They are commonly used in applications with high rotational speed, such as electric motors and gearboxes. Learn more in our ball bearing overview article.

Figure 2: Ball bearing components: inner and outer races (A), cages (B), and balls (C).

Ball bearing types

The following list provides an overview of various types of ball bearings, each with unique characteristics and specific uses. These bearings are critical in numerous applications, including precision instruments, micro-motors, gearboxes, and wheel hubs.

- Deep groove ball bearings: Deep groove ball bearings are the most common type. They can handle both radial and axial loads.

- Angular contact ball bearings:Angular contact ball bearings have higher than average internal axial clearance. They can handle axial loads in one direction and moderate radial loads.

- Self-aligning ball bearings:Self-aligning ball bearings can adjust to alignment errors. They can handle radial loads but minimal axial loads.

- Thrust ball bearings:Thrust ball bearings are designed specifically for high axial loads and insignificant radial loads.

- Miniature ball bearings: Miniature ball bearings are for precision instrument applications in limited space, such as micro-motors.

- Double row ball bearings: Double row ball bearings have two rows of balls and can handle higher loads.

Roller bearings

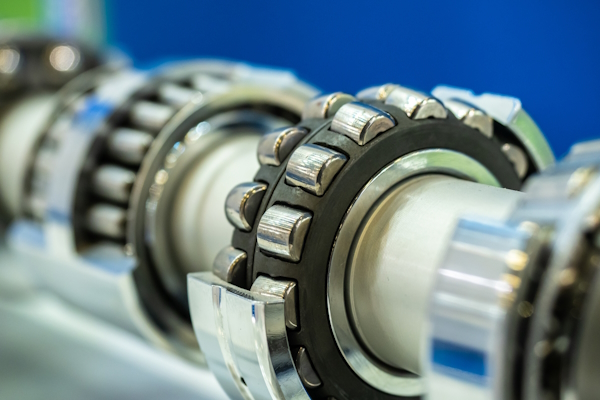

Roller bearings have cylindrical or barrel-shaped rolling elements. This bearing type is designed to carry heavy radial loads because of the greater contact area between the rollers and the raceway.

Figure 3: Roller bearings have cylindrical, barrel-shaped rolling elements.

Roller bearing types

The following list overviews various roller bearing types with distinct features and specific applications. These bearings play a crucial role in various scenarios, such as vehicle hubs, heavy machinery, and applications that require high load-carrying capacities. Read our roller bearing overview article to learn more.

- Cylindrical roller bearings: Cylindrical roller bearings have cylindrical rollers with uniform dimensions along their length. These bearings are suitable for carrying heavy radial loads and can operate at high speeds.

- Tapered roller bearings:Tapered roller bearings have conical rollers and raceways, making them ideal for vehicle hubs and other high-load applications. They can support large axial and radial forces.

- Spherical roller bearings:Spherical roller bearings are self-aligning and can withstand both heavy radial and axial loads. They are ideal for applications that involve misalignment or shaft deflection.

- Needle roller bearings: Needle roller bearings have thin, long rollers, making them suitable for applications with limited radial space but requiring high load-carrying capacity.

- Thrust roller bearings: Thrust roller bearings can handle large axial loads and are often used in heavy machinery such as drills and extruders.

Ball vs roller bearings

When comparing ball bearings and roller bearings, several factors come into play.

- Ball bearings are typically better suited for applications requiring high-speed operation due to their lower friction coefficient.

- Roller bearings, with their larger contact area, are ideal for applications with heavy radial loads.

- Ball bearings have a lower load capacity than roller bearings due to the smaller contact area.

- Ball bearings exhibit less deformation under load, making them more suitable for precision applications.

Selection criteria

Choosing the right bearing for a specific application is crucial for optimal performance and longevity. The selection criteria are largely based on the following two criteria:

- Load type and capacity: Bearings must be capable of handling the specific load, whether radial, axial, or combined. Roller bearings are typically chosen for heavy radial loads, while ball bearings are used for lighter loads.

- Speed requirements: The operating speed of the application plays a significant role. Ball bearings are preferred for high-speed applications due to their low frictional resistance.

Life expectancy, maintenance, and operating conditions are other factors to consider when selecting a bearing. These factors are specific to the application's needs. Learn more about selecting for these factors in our cylindrical bearing selection guide.

FAQs

What are the 2 main types of bearings?

The two main types of bearings are ball and roller bearings. Ball bearings offer higher speeds, whereas roller bearings can handle heavier loads.

What is the most common bearing?

Deep groove ball bearings are the most commonly used bearings due to their durability, versatility, and simplicity.