Tapered Roller Bearings

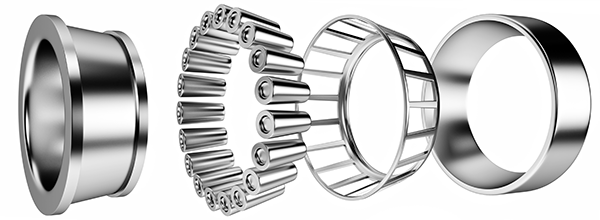

Figure 1: Tapered roller bearing assembly

Tapered roller bearings focus combination loads into a central rotational axis. They allow for the simultaneous action of radial and axial loads on the bearing assembly. The axial load-bearing capacity of a tapered roller bearing increases as the raceway contact angles increase—their conical shape results in less overall stress on the interfacing parts. Tapered roller bearings are used on motor shafts, axles, propellers, and countless other applications.

Table of contents

- Tapered roller bearing components

- What types of loads can tapered roller bearings handle?

- Single-row, thrust, or multi-row tapered bearings

- Selection criteria

- Common uses

- Extending equipment life cycles

- Pros and cons

- FAQs

View our online selection of tapered roller bearings!

Tapered roller bearing components

A tapered roller bearing consists of inner and outer rings which house the rolling elements. The rollers taper into conical shapes. The corresponding raceways that the rollers interface with are angled to accommodate their tapered form. The rollers themselves are held together in a cage (aka retainer) that fits the inner and outer rings. Figure 2 shows the main components which hold the rollers together.

Figure 2: Exploded view of a tapered roller bearing. From left to right: Inner raceway, rolling elements, cage, and outer raceway.

What types of loads can tapered roller bearings handle?

The angled and tapered shape of tapered roller bearings minimizes the stress caused by a combination of radial and axial loads. Radial and axial loads often combine to create different loads upon a bearing assembly. The ability to handle angular loads and changing angular loads – makes tapered roller bearings indispensable to various technical designs and industries. The tapered shape essentially concentrates radial and axial loads into a unified load that is more easily harnessed. Which angular loads can be harnessed depends on the precise angle of the tapered bearing. They can harness a comprehensive range of forces by configuring two or even more tapered bearings.

The steepness of the roller bearing's gradient increases the thrust/axial load it can handle, while a shallow angle increases the radial load capacity. As the radial load increases, the bearing experiences more stress against the sides of the bearing raceways. A more shallow angle minimizes stress, reducing pressure on the rollers. Increased axial load contributes to the stress applied to the top of the rollers. A steeper angle will distribute the pressure more towards the center of the bearing and less onto the rollers themselves.

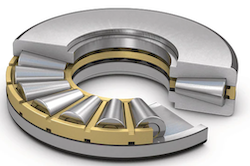

Single-row, thrust, or multi-row tapered bearings

Depending on the type and angle of the loads that will interact with the tapered roller bearing, you will need to find the tapered bearing with an appropriate angle. For multiple loads, there are several types of multi-row assembly options.

Figure 3: A double row tapered bearing (left), thrust bearing (middle), and a single row tapered bearing.

Single-row tapered roller bearing

A single-row tapered bearing is usually adequate for the most straightforward applications (e.g., angular forces on a fixed point and with only mild fluctuation). To find the right one, you'll need to determine whether the end-use of the tapered bearing will have more radial or axial loads. There are axial-only tapered roller bearings called thrust tapered bearings that resemble flat rings or disks where the rollers are perpendicular to the bearing bore axis. When multiple bearings are required, it could be advantageous to use two- or more single-row tapered bearings rather than multi-row bearings within a single housing. One such example is if one bearing will need to be maintained, adjusted, or replaced separately from the other. Another is when there is a need to allow for flexibility in design and add or subtract individual single-row tapered bearings, which is impossible with a multi-row tapered bearing.

Multi-row tapered bearings are inherently more secure because they operate in the same housing. That housing is more prominent and provides more surface area to connect with the equipment it interfaces with, providing more stability and higher longevity.

Multi-row tapered roller bearings

If a tapered roller bearing must withstand different angles of axial thrust, one can integrate multiple rows of rollers (most typically two or four) into one unit. These roller rows can be either adjacent to each other or spaced apart. These bearings are identified according to how the multiple rows are oriented towards each other and include:

- Tandem: Adjacent roller rows are oriented with the same load-bearing direction in the same bearing.

- Double-cup: The apexes (or 'vanishing points') focused on by the two adjacent roller retainers face inwards towards each other within a single, double-grooved outer raceway.

- Double-cone:The rollers are housed side-by-side such that the 'apex' of each faces outwards and away from each other.

- Spacer-assembled: Any pair of single-row bearings separated by spacers or a wider cage within the same assembly. The single-row bearings can be oriented just as with tandem, double-cup, or double-cone arrangements according to the same principles – the key difference is that they are distanced and not right next to each other. An example of this is seen in Figure 4.

Figure 4: Spacer-assembled tapered roller bearing

Selection criteria

Tapered roller bearings are the most common solution when interfacing with combined forces, especially changing ones.

- Non-combination forces: Ball bearings and other simpler alternatives have less friction overall and are likely sufficient for non-specialty purposes that lack combination forces or a need for high surface-area contact.

- Combination forces: A combination of axial and radial loads almost always requires a tapered roller bearing.

- Determining load capacity: The contact angle determines the load capacity, so it's essential to decide the load angles a bearing will handle. For heavy-duty applications, multi-row tapered bearings are necessary for combination loads. With lighter forces, one is often enough.

- Determining contact angles: The contact angle between a component and the bearing will determine the outer ring raceway angle. More significant contact angles translate to higher axial load capacities and vice versa. When selecting the correct tapered bearing for your needs, you'll see this angle often expressed with the coefficient 'e'; higher values indicate both greater contact angles and axial load-bearing capacity.

Shallow, moderate, and sharp contact angles

Generally, an angle of 10° to 19° is very common for radial load-heavy applications. For anything less than 10°, you should consider if you need a full-thrust roller bearing and investigate whether or not there is much radial force at all. As axial loads increase (and radial loads decrease), 20° and 24° is a good balance. This angle is shallow enough that radial loads still won't put extreme pressure on the bearings but steep enough to handle axial loads more effectively. For large axial loads, angles between 25° and 29° are necessary, and this is the point where radial loads will create more wear and reduce the component's lifespan. Still, it is more than adequate to handle a high mix of radial- and axial-combination loads simultaneously.

Angular contact ball bearings can be equally effective in handling various loads. Read our technical guide on angular contact ball bearings to learn more.

Common uses

A tapered roller bearing is appropriate wherever a bearing must handle combination loads. One of the most common uses is maintaining axial balance, achieved with multiple tapered roller bearings along an axle or shaft. The tapered bearings will evenly distribute loads when adequately aligned, minimizing wear and tear on the components. With higher surface area, tapered roller bearings can distribute friction and heat from combination loads more efficiently than non-tapered rollers (which are more efficient than tapered bearings only with the most straightforward non-combination forces). This reduced friction increases the rotational speed of interfacing parts and makes tapered roller bearings ideal for use in:

- Engines

- Motors

- Gearboxes (especially those with helical gears)

- Wheels & axles

- Turbines & propellers

This equipment must combine many different angles and utilize them to drive motors, driveshafts, and other rotational components.

Extending equipment life cycles

In high-speed applications, standard bearings will break down much more quickly and damage the components they interface with. Compared to their non-tapered counterparts, tapered rollers combine less friction with high surface-area contact with extremely fast-rotating parts. The result is a highly efficient transfer of combined forces and shifting forces into a single rotational axis. This efficiency translates to much less vibration, which prevents damage to delicate instruments throughout the machine and reduces the need to dampen outside force.

Pros and cons

The pros of tapered roller bearings

- High reliability: Tapered roller bearings are highly reliable when used correctly. Automobiles can run for hundreds of thousands of miles without experiencing tapered bearing failures, requiring little-to-no maintenance.

- Combined and varied loads: Tapered roller bearings have clear advantages over spherical, cylindrical, and needle roller bearings when handling combined and varied loads due to their geometry.

- Load bearing capacity: Tapered bearings can support pure axial and radial load.

- Minimum load requirement: The rollers are very unlikely to slide or 'skid' when loaded or unloaded; other roller bearings have minimal load requirements – a consistent amount of pressure that must be maintained – to prevent the rollers from sliding within their raceways.

The cons of tapered roller bearings

- Speed: Because the rollers maintain high surface area contact – an advantage in some regards (such as distributing loads evenly) – they do not match the speed potential of spherical bearings, which have less internal friction and generate less heat.

- Heat: Compared to non-tapered rollers, tapered rollers generate less heat because there is less material, and the bearing cage with rollers is less bulky.

- Dynamic misalignment: Spherical bearings are better at tolerating dynamic misalignment than tapered bearings because they have been designed for particular angles and respond poorly to gradients outside of their design purpose. Spherical bearings can handle temporary shifts without much stress on the unit because the balls float independently within their retaining cage. With tapered rollers, any pressure exerted on one will spread thoroughly throughout the entire assembly.

FAQs

How long will a tapered roller bearing assembly last?

When properly selected, fit, sealed, and lubricated, tapered bearings last for a very long time and with minimal maintenance. They tend to be some of the last parts of a machine requiring service.

How to adjust tapered roller bearings?

The roller cage can bend if too loose, scarring the raceway surfaces. If too tight, there is constant friction that creates small metal shavings. Eliminate 'play' and back off until it spins freely.

When should I replace a tapered roller bearing?

Metal flaking indicates that the tapered bearing should be replaced as soon as possible. Also, stethoscopes can help detect grinding or squeaking noises that could mean significant wear.