Thread Tolerance

Thread tolerance dictates how much a thread can deviate from the basic profile and achieve a proper connection. Mass production of threaded fasteners requires efficiency and therefore perfectly sized threads (to the micrometer) are not likely. However, for general purposes, a thread does not need to be perfectly sized in order to work as it should. Thread tolerance data provides manufacturers with the information they need to ensure the threads they produce are in the window of acceptability. A high thread tolerance informs consumers that the threaded fastener is for general use. A low thread tolerance, on the other hand, informs consumers that the thread is for a specialized use, for example in the aerospace industry, which requires high precision.

Table of contents

Explore Tameson's selection of thread cutting tools

Thread tolerance designation

The most common application for thread tolerance is coated threads. In fact, the metric thread tolerance standard (ISO 965) only discusses thread coating as a reason for thread tolerance. This article explains in detail tolerance classes for metric and unified thread standard (UTS) threads. To learn more about threaded fasteners, read our articles on thread design and thread standards.

Thread designations have an extra number and letter combination after the typical designation to designate thread tolerance. An example of a typical designation is M10 x 1. The letter M denotes this as a metric thread, 10 is the nominal diameter in millimeters, and the x 1 means the thread’s pitch is 1 millimeter. Read our metric thread standard overview to learn more about metric threads and their designations.

The format for thread tolerance designation follows these rules:

- Letters: Metric thread tolerance uses capital letters for internal threads and lowercase letters for external threads. These letters also designate tolerance position. For a UTS screw thread, A indicates external, and B indicates internal.

- Numbers: Numbers indicate the tolerance grade.

- Order: Pitch diameter tolerance comes before major diameter tolerance.

Tolerance letter designation

Metric threads

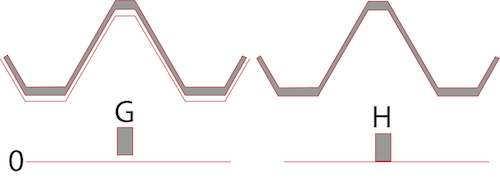

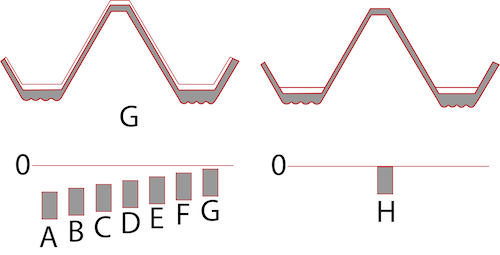

The letters A-H are in the metric tolerance system. Internal threads only use G and H, and external threads use a-h. As seen in Figure 2, H describes tolerance with zero deviation from the basic profile, and G describes tolerance with deviation above the basic profile. As seen in Figure 3, h describes tolerance with zero deviation from the basic profile, and g-a describe tolerance with deviation below the basic profile, which is a theoretical thread profile. An external thread’s dimensions must always be equal to or smaller than the basic profile. Internal thread dimensions must always be greater than or equal to the basic profile.

Figure 2: Metric internal thread tolerance deviation positions H (zero deviation) and G (positive deviation).

Figure 3: Metric external thread tolerance deviation positions h (zero deviation) and g-a (negative deviations).

Some examples of deviation amounts are seen in Table 1. Refer to ISO 965 for a full description.

Table 1: Examples of fundamental deviations for internal and external metric threads.

Pitch |

Fundamental deviation (µm) |

|||||||||

Internal thread |

External thread |

|||||||||

| G | H | a | b | c | d | e | f | g | h | |

| 0.5 | +20 | 0 | - | - | - | - | -50 | -36 | -20 | 0 |

| 1 | +26 | 0 | -290 | -200 | -130 | -85 | -60 | -40 | -26 | 0 |

| 2 | +38 | 0 | -315 | -225 | -150 | -105 | -71 | -52 | -38 | 0 |

UTS threads

UTS thread tolerance designation uses only two letters, A and B. The letter A signifies external threads, and the letter B signifies internal threads.

Tolerance grade designation

Metric threads

Metric threads use the numbers 3-9 to designate tolerance class. The higher the number, the looser the tolerance. There are four groups of tolerance grades:

- Internal thread minor diameter: 4, 5, 6, 7, 8

- External thread major diameter: 4, 6, 8

- Internal thread pitch diameter: 4, 5, 6, 7, 8

- External thread pitch diameter: 3, 4, 5, 6, 7, 8, 9

The following tables are examples of these four tolerance grades. Refer to ISO 965 for complete tables.

Table 2: External thread major diameter tolerances

Pitch (mm) |

Tolerance grade (µm) |

||

| 4 | 6 | 8 | |

| 0.3 | 48 | 75 | - |

| 1 | 112 | 180 | 280 |

| 2 | 180 | 280 | 450 |

Table 3: Internal thread major diameter tolerances

Pitch (mm) |

Tolerance grade (µm) |

||||

| 4 | 5 | 6 | 7 | 8 | |

| 0.25 | 45 | 56 | - | - | - |

| 0.75 | 118 | 150 | 190 | 236 | - |

| 1.5 | 190 | 236 | 300 | 375 | 475 |

Table 4: External thread pitch diameter tolerances

Basic major diameter |

Pitch (mm) |

Tolerance grade (µm) |

|||||||

| Over (mm) | Up to and including (mm) | 3 | 4 | 5 | 6 | 7 | 8 | 9 | |

| 0.99 | 1.40 | 0.30 | 28 | 36 | 45 | 56 | - | - | - |

| 5.60 | 11.20 | 1.25 | 60 | 75 | 95 | 118 | 150 | 190 | 236 |

| 22.40 | 45 | 2 | 85 | 106 | 132 | 170 | 212 | 265 | 335 |

Table 5: Internal thread pitch diameter tolerances

Basic major diameter |

Pitch (mm) |

Tolerance grade (µm) |

|||||

| Over (mm) | Up to and including (mm) | 4 | 5 | 6 | 7 | 8 | |

| 1.40 | 2.80 | 0.20 | 42 | - | - | - | - |

| 2.80 | 5.60 | 0.35 | 56 | 71 | 90 | - | - |

| 11.20 | 22.40 | 1 | 100 | 125 | 160 | 200 | 250 |

UTS threads

Although UTS has five classes (similar to ISO grades), only three are in regular use:

- Class 1: Tolerance for loose fit threads for easy use, even in dirty environments.

- Class 2: Class 2 tolerance is the most common and maximizes strength.

- Class 3: Class 3 tolerance threads have a medium fit for high-quality work.

Class 4 is a theoretical class that is now obsolete because class 3 overlaps with it. Class 5 threads are interference threads, meaning a wrench is necessary to tighten them. Class 5 threads are meant to be permanent or semi-permanent.

Tolerance designation order

Metric threads

In the case of a tolerance designation that describes a thread fit (external and internal), the internal comes first. A slash separates the internal and external designations. For example, 5H/5g6g.

The pitch diameter comes first in the case of two tolerance designations for an external or an internal thread. For example, 5g6g means the pitch diameter class is 5g, and the major diameter tolerance class is 6g.

In the case of one tolerance designation for an external or an internal thread, the pitch diameter, and nominal diameter are the same. For example, 5H means that the internal thread’s pitch diameter tolerance is 5H, and the minimum diameter tolerance is also 5H.

UTS threads

The designation order is simpler for UTS thread tolerance. It is always a number followed by a letter. For example, 1B or 2A.

Recommended tolerance classes

ISO 965 gives specific tolerance class recommendations based on thread coarseness and thread engagement length.

- Thread coarseness: fine, medium, and coarse

- Thread engagement length: short, normal, and long

Designating the thread engagement length is based on the major diameters and pitches of external and internal threads. ISO 965 gives further precise details on these variables. For common use, ISO 965 recommends 6H and 6g, or 6H/6g medium, normal-length threads.

The UTS thread standard recommends tolerance classes based on the application. Class 1 for applications that have loose requirements, Class 2 for most applications, and Class 3 for high-quality applications.

Read our thread compatibility article for more details on the compatibility of thread types.

FAQs

What is thread tolerance 6H and 6g?

Thread tolerance 6H is the recommended tolerance for metric internal threads. Thread tolerance 6g is the recommended tolerance for metric external threads.

How is thread tolerance designated?

Thread tolerance is a number and letter combination after the typical major diameter and pitch designation. For example, M8 x 1.75 - 6H describes an internal thread with 6H tolerance.