What Are Pressure Gauge Snubbers?

Figure 1: Pressure gauge snubber

When integrated into mechanical systems, the pressure gauge snubber serves a critical role in suppressing excess force or rapid motion ('snub'). A pressure snubber dampens the effects of pressure spikes and pulses, allowing the pressure gauge to remain readable and extend its service life, for example, when using a pressure gauge for high-pressure cleaners. With capabilities of handling a range of media, these units can handle a variety of media from water, steam, oil, and gasoline to air and other gases. It is important to note that it does not alter the process pressure.

Online selection of pressure gauges

Table of contents

- Types of gauge snubbers

- Liquid filled pressure gauges and snubbers

- Tips for selecting and operating the right pressure gauge snubber

- FAQs

Types of gauge snubbers

There are a wide variety of pressure gauge snubber designs available on the market, such as: low cost porous disc types, piston-type snubbers, adjustable gauge-snubbers, and more. In this article we discuss the three most common types.

Porous disc type snubber

Porous snubbers have a fixed mesh disk that the incoming media has to go through before it reaches the pressure gauge and allows consistent pressure at low speeds. Depending on the process media being monitored, porous disc snubbers have the disadvantage of potentially becoming clogged over time. It has to be cleaned with a solvent from the gauge side in that case.

Figure 2: Porous disc type snubber

Piston-type snubber

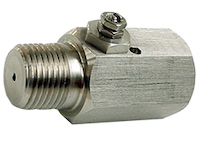

Piston-type snubbers have the advantage of being self-cleaning so that debris does not clog the system. Piston-type snubbers have a free moving piston inside of the snubbers body. If the pressure increases rapidly, it moves the piston against the gauges orifice. This dampens the pulsation the gauge sees, but there is still a media bypass when the piston is closed. This reduction in the pulse is only a few milliseconds, but enough to prevent damage to the gauge.

It is possible to tune this type of snubber easily by changing its pistons to suit the processs requirements; some snubbers come with up to five different pistons. Several factors affect the rate of dampening of the piston, including the diameter and clearance within the snubber.

Figure 3: Piston-type snubber

Adjustable pressure gauge snubber

An adjustable snubber further refines the level of fine tuning. A typical adjustable snubber is a piston-type snubber with the addition of a needle valve. The needle valve further restricts the flow before it enters the snubber. The piston-type snubber may also be a check ball valve, which operates along the same principle of it being passive until a sudden change in pressure triggers it into action. Some adjustable snubbers also come with leak-tight shutoffs, allowing the gauge to be removed for repairs or maintenance.

Figure 4: Adjustable pressure gauge snubber

Liquid filled pressure gauges and snubbers

A liquid filled pressure gauge can serve the same purpose as a gauge snubber, in that it reduces pulsations in the pressure reading. However, a liquid filled pressure gauge is typically more expensive than a normal pressure gauge with a snubber. In addition, some applications require more vibration dampening than what a liquid filled pressure gauge or gauge snubber can do alone. Therefore, they can also be used together for further vibration dampening.

Tips for selecting and operating the right pressure gauge snubber

A pressure snubber equalizes the rate at which a fluid or gas arrives at the measuring point. The use of a snubber in pressure gauge applications does not alter the process pressure, it will reduce pulsations on the line, thus improving the accuracy of gauge readings, and extending the life of that specific gauge.

- Price: A snubbers price varies depending on several factors. In the low end of the spectrum is the porous disc snubber, but can come clogged and cant be fine-tuned. Snubbers with piston mechanisms tend to be more expensive, but dont get clogged and can be tuned.

- Housing material: The housing material is often brass or stainless steel, although materials like Monel and steel are also used. The below table shows brass and stainless steel as a guideline to snubber pressure ratings.

-

Snubber chemical compatibility: For the most part snubbers are made out of copper alloys like brass or stainless steel. Although stainless steel has superior chemical resistance, these snubbers do tend to be more costly. If your application does not need to have these properties a brass snubber would be the preferred option. More information on chemical compatibility of materials can be found in our article on the chemical resistance of materials and our housing material guide.

- Brass snubbers: Brass snubbers are suitable for neutral and non- corrosive media. They are resistant to water, (compressed) air, oils and many other media. However, brass should not be used with salt or seawater, distilled water, acids, and chlorides.

- Stainless steel snubbers: These have the advantage of being chemically resistant to almost any medium except hydrochloric acids, chlorides, bromine and household bleach. It has high wear, temperature, and pressure resistance.

- Dynamic load cycles: Various processes subject pressure gauges to temporary heavy loads, also called vibrations or pulsations. The measurement instrument can be permanently damaged by these dynamic load cycles, for example from a reciprocating pump. Before purchasing a snubber determine the load cycles in your system. Installing the correct snubber for the load cycles in a system will prevent excess costs and damage to vital components.

- Temperature: High temperatures can affect pressure gauges as well as load cycling, depending on the process. Adding a syphon can be advantageous in such cases. The protection is particularly effective when hot media, like vapour, are present in conjunction with load cycles.

- Pressure suitability: When choosing a pressure snubber, ensure that it is appropriate for the process in which it will be used. Installing a snubber rated at a lower pressure in a highly pressurized system will be problematic. Snubbers should be selected based on the pressure range determined by the pressure generated by the system. Snubber pressure ratings vary from low pressures to 36000 PSI (2500 bar). The pressure rating of a snubber depends on the type, orifice size, material, and thread size. Table 1 shows the maximum pressure rating for stainless steel and copper alloys for each thread size. Read our article onpressure types article for more information on different pressure types such as absolute and atmospheric pressure.

Table 1: The maximum pressure rating for stainless steel and copper alloys for each thread size

| Copper Alloys | Stainless Steel | |||

|---|---|---|---|---|

| Thread | Bar | PSI | Bar | PSI |

| G ⅛ | 400 | 6000 | 400 | 6000 |

| G ¼ | 600 | 8600 | 1000 | 15000 |

| G ⅜ | 600 | 8600 | 1000 | 15000 |

| G ½ | 1000 | 15000 | 2500 | 36000 |

| M10 X 1 | 400 | 6000 | 400 | 6000 |

| M12 X 1.5 | 400 | 6000 | 400 | 6000 |

| M20 X 1.5 | 1000 | 15000 | 2500 | 36000 |

| ⅛ NPT, R ⅛ | 400 | 6000 | 400 | 6000 |

| ¼ NPT, R ¼ | 600 | 8600 | 1000 | 15000 |

| ⅜ NPT, R ⅜ | 600 | 8600 | 1000 | 15000 |

| ½ NPT, R ½ | 1000 | 15000 | 1600 | 23000 |

| 7/16-20 UNF | 400 | 6000 | 800 | 12000 |

There are many similarities between the selection criteria for snubbers and those for pressure gauges. Read our selection tips for pressure gauges to learn more. In our article on pressure gauges you can learn all about the different types of pressure gauges and how they work such as bellows pressure gauges, diaphragm pressure gauges, or bourdon tube pressure gauges.

FAQs

What is a snubber for a pressure gauge?

The pressure snubber is a specific fitting attached to a pressure gauge before the media reaches it that evens out pressure fluctuations.

Does a residential steam boiler pressure gauge need a snubber?

A snubber is usually not needed for residential steam applications. Occasionally, pressure spikes in industrial steam boilers require a snubber.

Do I need a snubber with electronic fuel gauges?

While not strictly necessary for fuel systems, a fuel pressure snubber valve does offer protection in case of sudden pressure spikes. A relatively inexpensive snubber protects the more expensive electronic fuel pressure gauge.

What are the steps in pressure gauge snubber installation?

A snubber is simply installed between the system line and the pressure gauge. When installing a snubber ensure you have one that corresponds to the thread diameters of the pressurized line and the pressure gauge.