Pneumatic Cylinder Mounting Styles

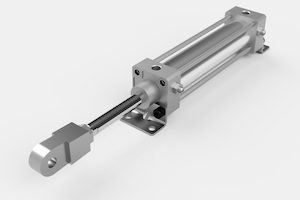

Figure 1: A pneumatic cylinder with foot mounting

Pneumatic cylinders are usually installed in one of three styles: fixed centerline, fixed offset, or fixed pivot. The choice of mounting style generally depends on the available space for attaching the pneumatic cylinder to a surface. However, knowing the pros and cons of each mounting style can be beneficial when there are several options for a single application. Discover more about cylinders in our pneumatic cylinder overview article.

Table of contents

View our online selection of pneumatic cylinders and mounting accessories!

Fixed centerline mount

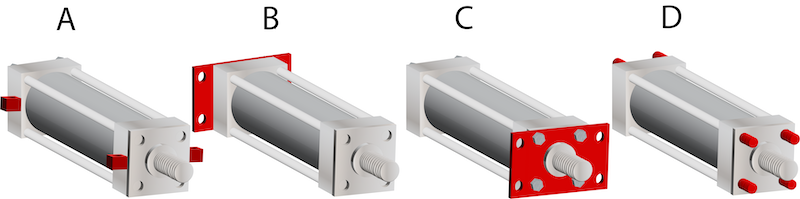

Pneumatic cylinders that mount on a fixed centerline (Figure 1) take on force along their middle line. This mounting style spreads forces equally across mounting bolts and is ideal for loads that need to be moved in a straight line. Side loads are lowered during activation, and the risk of misalignment is lessened, which mitigates the stress on the piston and rod bearings, preventing early failure. As seen in Figure 2, the three main types of centerline mounting are lug, flange, and tie rods.

- Centerline lug (A): Rectangular tabs near the midpoint of the cylinder's head and cap secure the cylinder to the mounting surface. This type of mounting is suitable for straight-line force applications. Centerline lug-mounted cylinders must be mounted with dowel pins for high shock or pressure applications.

- Flange (B & C): Flanges mount on the cap-end (back) or rod-end (front) depending on if the load is subjected to a push or pull force, respectively.

- Cylinder tie rod (D): Cylinder tie rod mounting extends the tie-rods on either side of the cylinder to attach to a mounting surface. Tie-rod mounted cylinders absorb thrust or tension force along the cylinder centerline, making it suitable for absorbing loads without subjecting the mounting bolts to shear stress. These cylinders typically follow NFPA standards, increasing their modularity among cylinder parts.

Figure 2: Common centerline mounting styles and their accessories: centerline lug (A), flange (B & C), and tie rods (D).

Fixed offset mount

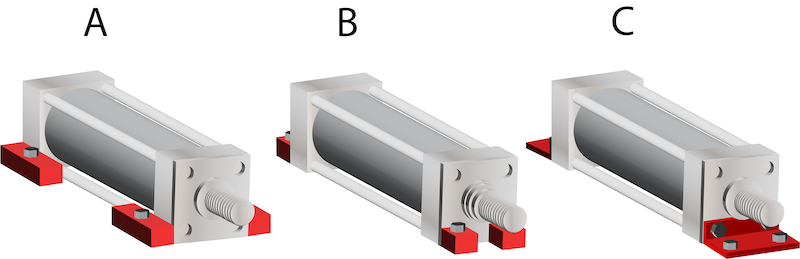

Pneumatic cylinder fixed offset mounting refers to the cylinder being mounted at the cylinder's sides or feet instead of its center. This mounting style allows easy installation and can be used for push and pull applications. Since the mounting is offset, though, side loads can easily occur. Fixed offset-mounted cylinders need to be pinned or keyed to absorb the stress of side loads. The two most common types of offset mounting are side mount and foot mount (Figure 3).

- Side mount (A): Side mount cylinders are rigidly mounted to a surface and absorb force away from the cylinder's centerline. The mounting surface must be able to absorb torque from the mounting bolts and cylinder during operation.

- Foot mount (B & C): Foot mount attachment can be used on the front and back of the cylinder for mounting. Cylinders with a large bore and short stroke have increased shear stress and may cause misalignment issues for foot-mounted cylinders.

Figure 3: Common offset mounting styles: side mount (A) and foot mount (B & C).

Fixed pivot mount

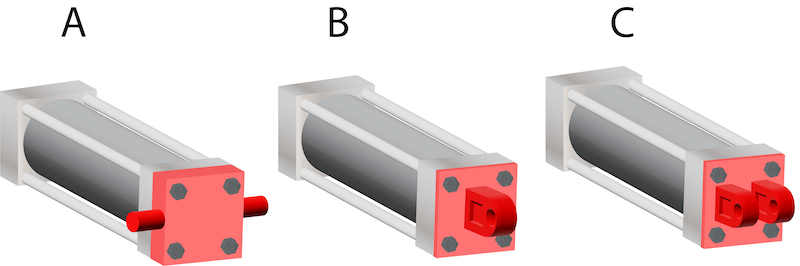

Pivot mount cylinders fix to a surface and absorb force along the cylinder's centerline. This mounting style allows for alignment changes in one plane. This can absorb slight misalignment to protect the cylinder rod from bending stresses. Also, this mounting style is often used with accessories, such as rod-end attachments, that provide a pivot point. Despite the relative rotational freedom, the piston rod will be subjected to bending stresses if the rod is not guided correctly. The two most common pivot mounting types are trunnion and clevis. (Figure 4).

- Trunnion (A): Trunnion attachments can be mounted at the cap-end, rod-end, or intermediate position. Rotation around a trunnion attachment is similar to rotation around a clevis attachment; however, trunnion attachments can only be used with shear stresses and not bending stresses. Tightly fit the trunnion bracket to reduce bending stresses to the trunnion pins.

- Clevis (B & C): Clevis attachments can be bolt-mounted to the cap-end of the pneumatic cylinder. The bolts that secure the clevis attachment can handle the shear forces generated from the opposing forces generated during cylinder actuation. A female or male-style coupling can be used depending on the coupling the clevis mounts to.

Figure 4: Common fixed pivot mounting styles: trunnion mount (A) and clevis mount (B & C).

Selecting a mounting style

The purpose and function of the pneumatic cylinder selected for a given application must be well understood to properly select a mounting style. Benefits of proper cylinder mounting include increased cylinder performance, reliability, and optimized usage of mounting space.

- Load travel displacement: The path the load must travel will define whether the cylinder will be fixed to a mounting surface or free to rotate about a pivot point.

- Required cylinder force: The required force will determine if the cylinder will provide a push or pull force on the load. Selecting suitable mounting attachments for the required force is necessary for proper cylinder function. Components such as mounting bolts or mounting surfaces can prematurely fail if not sized with mounting attachments.

- Standards: Before choosing a mounting style, determine if it matches with the application's pneumatic cylinder. For example, ISO 6432, ISO 15552, and ISO 21287 pneumatic cylinders.

- Mounting structure and space: The structure in which the cylinder is mounted must be able to withstand the shear stress during actuation. Side mount cylinders will expose the mounting surface to additional shear stress during actuation.

- Load alignment: The alignment of the cylinder to the load will be critical to prevent side loading and excessive wear on the cylinder components. Centerline loading of the cylinder is ideal as it distributes force evenly along the cylinder. If a side mount attachment is required, the mounting surface and bolt should be sized correctly. If misalignment is possible, an attachment, which will compensate for the misalignment, will be required.

- Pivot angle: Pivot-mounted cylinders must consider the actuation angle with respect to the load, as the effective force on the load will be decreased depending on the angle.

- Operating environment: The dimensions or alignment of mounting attachments or accessories may change under extreme environmental conditions such as temperature or vibration. To prevent misalignment or cylinder failure, operating conditions must be taken into consideration.

FAQs

What are the different pneumatic cylinder mounting styles?

The different pneumatic cylinder mounting types are fixed centerline, fixed offset, and fixed pivot.

How do you mount a pneumatic cylinder?

There are different ways to mount a pneumatic cylinder to a surface. It depends on the space available to mount the cylinder to a surface.