The Use of Oil Absorbing Sheets in Preventing Workplace Hazards

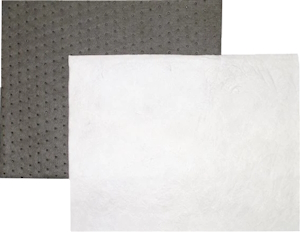

Figure 1: Oil-absorbing sheets are important for reducing risks in a workplace.

Oil-absorbing sheets are essential in industrial settings as they are designed to wick away hydrocarbons such as oil and fuel from surfaces. This reduces the potential for slips, fires, and environmental contamination. Composed of porous, high-absorption materials, they selectively soak up oil-based liquids while repelling water. By understanding how to prepare and use these sheets, facilities can maintain safer work environments and comply with health and safety regulations.

The following is a list of common oil sheets found in workplaces:

- Oil-only absorbent sheets: These are often white, making it easy to see when they absorb oil. These are especially for oil-based spills and are useful on water or in rainy conditions.

- Universal absorbent sheets: These are typically gray and made from meltblown polypropylene. These sheets can absorb water, coolants, solvents, and oil-based fluids.

- Hazmat absorbent sheets: These are usually yellow or other bright color and are made from chemically resistant materials. These sheets are for cleaning up hazardous and aggressive chemical spills.

- Static-resistant absorbent sheets: These sheets are made with a static-dissipative fabric or coating, often in a pink color to indicate their anti-static properties. These are for absorbing flammable liquids in environments where static electricity poses a risk of ignition.

View our online selection of oil absorbent sheets!

Table of contents

Prepare for hazards

To be prepared for oil spills in the workplace, workplaces must determine the specific absorbent sheet requirements. Facilities should have various types of sheets, categorized by compatibility with different spill types. For example, workshops that handle machinery might have heavyweight sheets capable of absorbing large volumes of lubricants. Laboratories dealing with various chemicals may require universal absorbent sheets that can handle oil- and water-based fluids.

How do oil absorbing sheets work

Oil-absorbing sheets for cleaning up oil spills in a workplace are made from materials such as polypropylene or specially treated natural fibers (e.g., cotton and wool) that have oleophilic (oil-attracting) and hydrophobic (water-repelling) properties. When placed on or near an oil spill, the oil is drawn into the network of fibers or pores of the sheet through a combination of capillary action and adsorption. The oleophilic nature of the material ensures that oil is effectively absorbed and retained within the structure of the sheet. The hydrophobic quality prevents saturation by water, making the sheets ideal for cleaning up oil-based spills while minimizing waste and environmental impact.

Training

Personnel need to be trained in the proper use of oil-absorbing sheets. Staff need to know how to quickly identify the spill type and choose the correct absorbent material, whether for oil only or a broader range of substances. Regular drills can help reinforce this knowledge. Furthermore, personnel must know how to properly dispose of sheets after using them.

Personal protective equipment

An important step in being prepared for a spill is having the correct personal protective equipment (PPE) available. The type of PPE required can vary depending on the nature and severity of the spills. The typical minimum requirement for oil-spill PPE includes nitrile gloves to protect against skin contact with the oil, safety goggles, and non-slip boots. If volatile organic compounds (VOCs) are present, respirators are necessary to protect against inhalation of harmful vapors.

Figure 2: Safety goggles and gloves are minimum PPE requirements for cleaning oil spills.

How to clean up an oil spill

The process of cleaning a spill with oil-absorbent sheets varies slightly depending on the type of spill, but the general steps are similar. Below is a step-by-step guide for different spill types.

- Assess the spill: Quickly determine the extent and type of oil spilled. Ensure the area is ventilated if indoors.

- Equip PPE: Don safety goggles, gloves, and non-slip boots to protect against potential hazards.

- Containment: Use oil-absorbent booms or pads to encircle the spill, preventing it from spreading.

- Absorption: Place oil-absorbent sheets directly onto the spill, starting from the edges and working towards the center. Overlap sheets, if necessary, to cover the entire area.

- Removal: Carefully remove the sheets without dripping oil back onto the clean surface once the sheets are saturated. Place the used sheets in a proper disposal container.

- Disposal: If the sheet cannot be cleaned, or has been used too many times, follow local regulations for the disposal of oil-contaminated materials.

Each workplace needs to have spill response procedures that are tailored to the types of materials they handle. Training on these procedures, along with regular drills, will help ensure the safety and efficiency of the spill cleanup process. Always refer to the specific guidelines for the materials involved and consult with local environmental agencies for proper disposal methods.

After cleanup

Cleaning up an oil spill with oil-absorbent sheets is a critical first step in mitigating environmental damage and safety hazards. Here's what to do after the initial absorption of the oil:

- Assess the situation: Determine if the sheets have fully contained the spill. Additional measures will be necessary if the spill is large or the oil has spread to waterways or soil.

- Disposal of used absorbents: Check local regulations regarding the disposal of oil-soaked materials before disposing of used sheets. Ensure used sheets are placed in a labeled container showing the date of the spill.

- Secondary cleaning: After most of the oil has been absorbed, there may still be a residue on the surface. Use degreasers or other suitable cleaning agents to break down any remaining oil. If the surface is rinsed with water, be mindful of where the runoff is going.

- Documentation: Keep a record of the spill, including its size, location, the materials used for cleanup, and how the waste was disposed of.

- Prevent future spills: Investigate the cause of the spill and implement measures to prevent future incidents.

FAQs

How do oil absorbent sheets work?

Oil absorbent sheets are made of synthetic or natural materials that absorb oil and repel water.

What are oil absorbent pads made of?

Oil absorbent pads, or sheets, are made of polypropylene or natural fibers, such as cotton and wool.