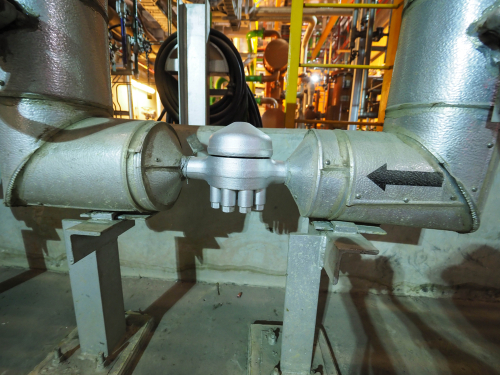

Needle Valve Applications

Figure 1: Needle valves installed in an oil processing station

Needle valves are used for precise control of fluids in low flow rate applications. They have threaded stems with tapered ends, allowing minute changes in fluid flow. Needle valves are widely used in water management, laboratory setups, and the oil, gas, and chemical industries.

- Stainless steel: Used in chemical processing, oil and fuel sampling systems, and handling corrosive media. They are durable and resistant to high temperatures (up to 200 𐩑C/392 𐩑F) and pressures (up to 300 bar/4351 psi).

- Brass: Ideal for potable water and non-reactive, non-corrosive liquids. They work up to 100 bar (1450 psi) and 110 𐩑C (230 𐩑F).

Applications

- Sampling operations

- Instrumentation and control systems

- Chemical and petrochemical industries

- Water management

- Oil, gas, and fuel industries

- Needle valves for steam traps

- Regulating pressure with needle valves

View our online selection of needle valves!

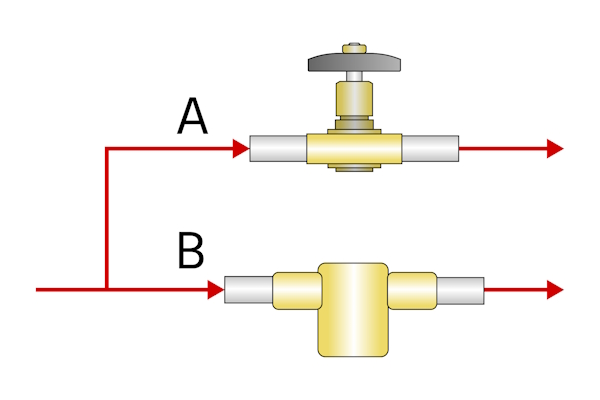

Sampling operations

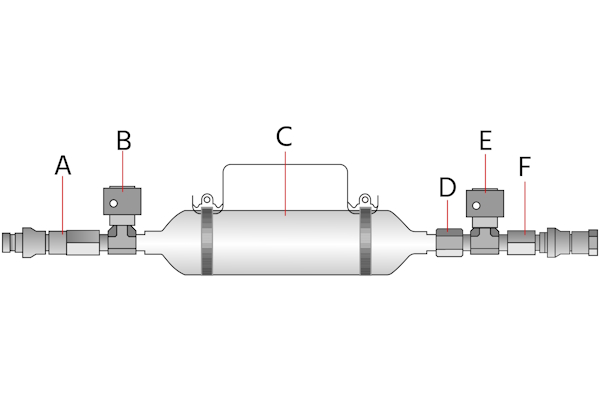

Figure 2: Needle valves for sampling operations: Quick-connect body (A), inlet needle valve (B), sample cylinder (C), outage tube (D), outlet needle valve (E), and quick-connect stem (F)

Needle valves are used to precisely control fluid flow in sampling systems (Figure 2). Use stainless steel needle valves with PTFE seals for sampling systems handling chemicals, solvents, or high-purity fluids. PTFE offers excellent chemical resistance, preventing sample contamination during transport.

- A quick-connect body (A) connects the system to the fluid source. The system has two needle valves: one at the inlet (B) and the other at the outlet side (E).

- The inlet needle valve opens to allow fluid flow into the sample cylinder (C). The needle valve ensures that the sample is collected at a controlled rate to prevent overfilling.

- After collecting the sample, both needle valves are closed to seal the cylinder. This secures the sample, preventing contamination or leakage during storage and transport.

- The needle valve on the outlet side is opened to let the fluid flow out of the sample cylinder.

- Controlling the discharge rate using the needle valve is essential, especially if the receiving system needs a specific flow rate for analysis or processing.

Read our needle valve overview article for more information on the design, working, and common features of needle valves.

Instrumentation and control systems

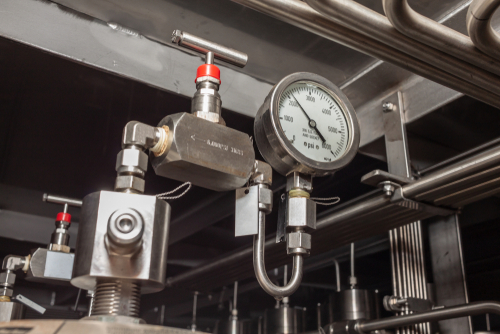

Needle valves allow gradual flow to pressure gauges, switches, or flow meters, protecting sensitive equipment from pressure spikes. They help maintain a constant, calibrated, low flow rate when needed. Needle valves are installed upstream of these equipment, allowing safe isolation during maintenance and repair. Choose stainless steel needle valves with PTFE seals when used with gas or hydraulic instrumentation to resist corrosion and maintain stable control under pressure. For general air or water service, brass with NBR seals is adequate.

Figure 3: Needle valve attached to a pressure gauge

Chemical and petrochemical industries

Needle valves control the flow of corrosive and hazardous chemicals with low viscosity.

- Accurate dosing and fluid metering: Needle valves provide exact control over flow rates, which is essential for accurate chemical dosing and mixing. They are also crucial for adding small amounts of catalysts or additives.

- Safety and system integrity: These valves allow complete shut-off, preventing leaks and spills of hazardous chemicals.

- Laboratory and analytical applications: Needle valves ensure precise chemical flow and enable accurate sampling in laboratory experiments.

- Purging, flushing, and system preparation: Needle valves control the flow of purge gasses or cleaning fluids. These are essential for removing contaminants and preparing systems for operation.

Select stainless steel with PTFE seals to handle corrosive, low-viscosity, or hazardous chemicals. PTFE maintains chemical stability and ensures precise metering even at elevated temperatures.

Water management

Water needle valves manage water pressure and flow rates in dams, reservoirs, power plants, and water distribution systems.

- Water level control: Needle valves are used as bottom outlets in dam and reservoir systems to manage water levels. They keep the system stable, even during heavy rain.

- Backwashing and cleaning: Needle valves control water flow in backwashing and cleaning cycles. This helps to clear debris and keep the system working efficiently.

- Chemical and filtration control: Needle valves manage the flow of chemicals and filtration processes in municipal and industrial water systems.

- Water treatment and desalination: These valves are crucial for effective water treatment and desalination. They are involved in chemical dosing, pH control, and flow regulation within pipelines and treatment systems.

- Water treatment plants: Needle valves regulate the flow of chemicals used for water purification.

Use brass with NBR seals for clean or non-corrosive water systems such as irrigation or backwashing. For chemical dosing, desalination, or chlorinated water, choose stainless steel with PTFE seals for corrosion resistance.

Example: Needle valve in an RO

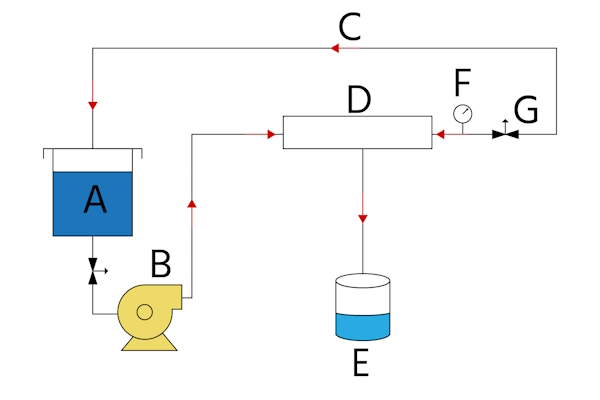

Needle valves are widely used in water purification, desalination, and industrial separation processes.

- A reverse osmosis (RO) system purifies water by using a pump (B) to pressurize water from the feed tank (A).

- It forces the water through a semi-permeable membrane in the RO spiral wound module (D).

- The membrane allows only water molecules to pass. This separates the clean water (E) from impurities (C).

- The needle valve (G) adjusts the pressure and flow rate exiting the membrane, ensuring optimal filtration performance.

Figure 4: Needle valve used in an RO system: Feed tank (A), pump (B), concentrate (C), RO spiral wound module (D), permeate (E), pressure gauge (F), and needle valve (G).

Oil, gas, and fuel industries

Needle valves regulate the flow of liquids, like gasoline, through pipes and hoses that connect to mechanical parts like pumps and motors. Additionally, they can control the flow of different gasses, such as air or natural gas, as they move from one area of an industrial plant to another. In pneumatic control systems, air needle valves regulate fluid flow to actuators and cylinders, reducing wear and tear. These valves monitor and adjust gas flow, such as propane, allowing precise control of flow rates.

Select stainless steel with PTFE seals for hydrocarbon gases, fuels, or lubricants, ensuring chemical resistance and tight shutoff. Brass with NBR seals suits non-corrosive, low-pressure air or diesel systems.

Example: Needle valve for a fuel system

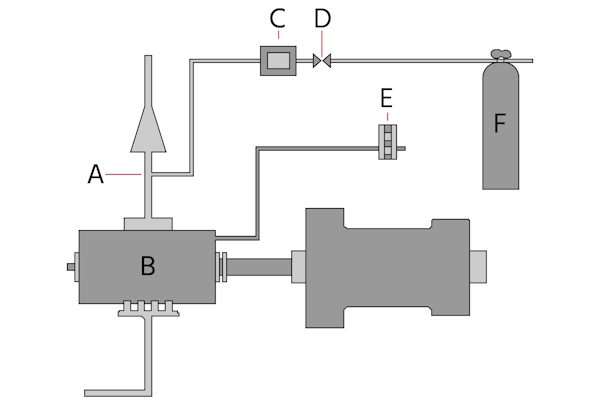

Figure 5 shows how a diesel engine works using both diesel and methane. The system's primary goal is to reduce emissions and lower fuel costs. This is achieved by replacing part of the diesel with methane, a cleaner-burning fuel.

- Fuel supply and regulation: The engine receives diesel from a traditional diesel tank and methane from a separate tank.

- Needle valve: The needle valve (D) controls the methane flow rate into the system. It allows for fine adjustments to ensure the correct amount of methane is mixed with the air before entering the engine.

- Flow measurement: The flow meter (C) measures the methane flow rate to accurately monitor and adjust the fuel mixture.

- Combustion: Methane is mixed with air in the gas mixer ring (A) before entering the engine (B). Diesel serves as a pilot fuel to ignite the mixture.

Figure 5: Needle valve for a dual fuel system: gas mixer ring (A), diesel engine (B), flow meter (C), needle valve (D), volumetric fuel measurement (E), two-stage regulator for methane (F)

Needle valves for steam traps

Figure 6: Steam trap used to remove condensate from a pipe

A steam trap removes condensate from steam. Sometimes, steam can close the trap valve prematurely, blocking condensate discharge and causing unexpected temperature drops.

An external bypass line can be installed to address this issue (Figure 7).

- Steam flow: Steam (A) is initially blocked by the steam trap. The steam then flows through a bypass line.

-

Needle valve: A needle valve in the bypass line allows some steam to pass through

- The needle valve is adjusted to allow less dense steam to pass through. The denser liquid condensate (B) is directed to the steam trap.

- Condensate drainage: The condensate is drained through the steam trap.

- Venting feature: If the steam trap has a venting feature, an internal needle valve can release any trapped steam.

Use stainless steel with PTFE seals for high-temperature and condensate service. Stainless steel withstands thermal cycling, while PTFE ensures leak-tight sealing under fluctuating pressure.

Figure 7: Needle valve (top) used to bypass steam (A) from steam trap (bottom). The steam trap lets the condensate (B) pass through.

Regulating pressure with needle valves

The flow rate changes when the pressure applied to a valve varies. A pressure regulator (Figure 8 labeled A) is often installed before the needle valve (Figure 8 labeled D) to maintain a steady pressure and a constant flow. This allows the needle valve to deliver consistent flow rates regardless of variations in the supply pressure.

Figure 8: Flow control with needle valve: pressure regulating valve (A), pressure gauge (B), constant pressure (C), needle valve (D), constant flow (E), and load (F).

FAQs

What is the main function of a needle valve in a fluid system?

The main function of a needle valve is to allow precise control and gradual adjustment of fluid flow.

What does a high pressure needle valve do?

A needle valve regulates and controls fluid flow precisely in high-pressure environments. They are used in hydraulic systems, oil and gas pipelines, and chemical processing.