What is a Foot Valve?

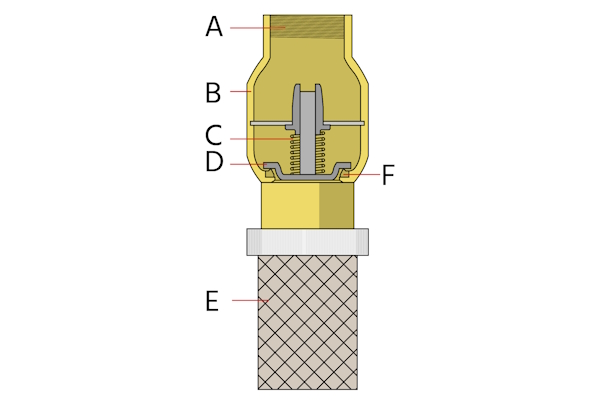

Figure 1: Foot valve

A foot valve prevents backflow, keeps pump suction lines primed, and has a strainer to prevent large debris from entering the system. Foot valves are necessary when pumps need to stay primed and the water source has debris (e.g., ponds, lakes, and wells). Foot valves work in wells and open water sources.

Table of contents

How does a foot valve work?

A pump foot valve's primary function is to stop a pump from losing its prime. When pumps draw water from a low point to a high point, and then the pump is turned off, the water may flow in the reverse direction due to the force of gravity. If this happens, the pump will not be primed and may get damaged the next time it is turned on.

When the pump turns off and backflow begins, the foot valve for the pump closes, preventing water from flowing out of the pump. Then, when the pump turns back on, the suction opens the foot valve, allowing flow from the water source to pass through the pump and into the rest of the system.

Foot valve parts and features

A typical foot valve has male or female threads for easy installation. Foot valves have the following basic parts:

- Connection (A): A foot valve has a threaded or flanged connection to attach to the pump or hose. This connection is only on the outlet side.

- Body (B): The body houses the complete valve mechanism. The body can be brass or stainless steel.

- Spring (C): The spring controls the closing speed and cracking pressure of the opening mechanism.

- Disc (D): This is the foot valve’s opening/closing mechanism that allows media to enter when the pump operates.

- Screen or strainer (E): The screen prevents sediments, debris, and other solid particles from entering the valve.

- Seat (F):O-rings made of NBR or FKM to prevent leakage when the pump is turned off and the valve is closed. The seat is where the valve disc rests when the pump isn't working.

Figure 2: Foot valve diagram: threaded connection (A), body (B), disc/closing mechanism (C), screen or strainer (D), and seat (E).

Cleaning the strainer

Like any strainer device, a foot valve requires regular maintenance to ensure it remains clear of clogs. A drop in pressure in the system is an indication that the foot valve should be examined for clogging.

If it is possible to lift the suction line without damaging anything, quick lifting and dropping a few times may be enough to dislodge anything stuck to the foot valve's strainer. If this is not possible, the foot valve must be removed entirely from the system so it can be cleaned directly.

Other maintenance

The main advantage of completely removing the foot valve from the system is that it provides the opportunity for other regular maintenance.

- Periodically inspect the foot valve for signs of corrosion and wear. Corrosion can cause the valve to malfunction or leak. It might also cause backflow, especially if the disc is damaged.

- Ensure the bottom of the tank is clean at all times to prevent sediments from clogging the strainer.

Applications

Besides water pumps, many pneumatic systems use foot valves due to their ability to prevent fluid backflow and maintain the fluid column when the pump is off. Foot valves keep the pump primed in the following applications:

- HVAC systems

- Car wash systems

- Ponds, pools, and wells

- Irrigation foot valve

- Sump pumps and intake pumps in rivers and lakes

- Rural fire protection systems

- Pneumatic brake lines for commercial trucks

FAQs

What is a foot valve, and how is it used?

A foot valve is a special type of non-return valve installed at the end of a pump suction in water or at the bottom of pipelines to prevent water from flowing backward when the pump is off.

What is the function of a strainer in a foot valve?

A strainer prevents debris and other solid particles from entering the suction line, which can clog the foot valve and damage the pump. It ensures efficient operation and a long lifespan of the valve.

How regularly should I clean the strainer?

Schedule a routine maintenance check-up based on factors such as the foot valve's workload, usage, and the level of debris in your water.