Needle Valve Applications

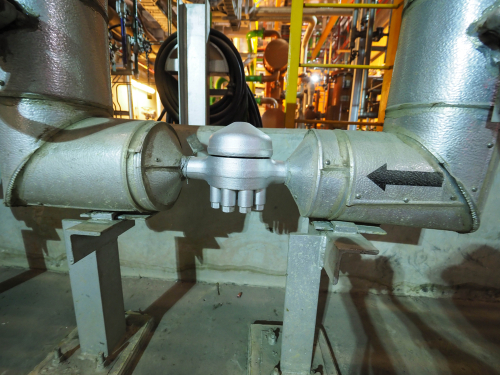

Figure 1: Needle valves installed in an oil processing station

Needle valves, also called plunger valves, are used to accurately control a fluid’s pressure and flow rate inside a pipeline. These valves are primarily used for low flow rates and high-pressure drops from inlet to outlet ports. Needle valves are commonly used in different systems and applications, like carburetors, water heaters, or flow metering devices. This article discusses how needle valves are used in common applications.

Table of contents

- Needle valves for fluid control

- Water needle valves

- Gas and propane needle valves

- Steam needle valves

- Needle valves for pressure gauge and flow meter

- FAQs

View our online selection of needle valves!

Needle valves for fluid control

A needle valve regulates fluid flow through an appliance or system. The valve has a needle-like plunger that tightly fits into the seat. The seat is typically a part of the appliance that is being regulated. If the valve handle is turned, space opens up between the needle and the seat, resulting in a minimal fluid amount able to pass through the needle valve. A significant number of turns is required to open up even a small amount of space under the plunger. This slow opening enables accurate control over the amount of fluid that can pass through the valve.

Needle valves can be operated manually or connected to an automated system. Automated needle valves connect to a pneumatic actuator or a hydraulic motor that automatically opens and closes the valve according to timers or external performance data.

The entire operation of the needle valve, besides the turning of the handle, takes place inside the valve; hence, it is impossible to visually measure the media flow. The lack of visual feedback regarding the exact flow rate placed on a system is one issue with having a manual needle valve. This problem can be eliminated through the use of automated needle valves.

Water needle valves

Needle valves aid engineers in regulating and controlling water pressure and flow rate. Needle valves are used in dams, reservoirs, power plants, and water distribution systems for:

- Flow control

- Pressure regulation

- Starting a pump

- Turbine bypass

- Discharge

- Reservoir inlets

Needle valves are also used in constant pump governors to reduce the fluctuations in pump discharge pressure.

Common devices

Ice-making devices commonly employ needle valves as expansion valves. The expansion valve decreases the refrigerant pressure, thereby reducing its temperature. Needle valves are ideal for this purpose as they can achieve extremely low refrigerant flow rates, thus decreasing the pressure. The valve also controls the amount of refrigerant entering the evaporator. Read our article on HVAC valves for more details on the refrigeration and air conditioning cycles.

Small needle valves known as bleed valves are used in water heating applications because of their compact structure. These valves also ensure that the water heater runs at maximum efficiency without using excess water.

Brass is suitable for the valve material if the medium is non-corrosive, whereas stainless steel is usually preferred for highly corrosive media like seawater or acids.

Figure 2: A boiler room containing needle valves (highlighted), pumps, and reservoirs.

Gas and propane needle valves

A needle valve allows the gas supply to be slowed down substantially before being shut off, thus effectively minimizing the strain on internal components and machinery.

- Needle valves are used in vacuum systems to release a steady amount of gas without substantial pressure. Needle valves are also used in elevated-temperature and oxygen service applications.

- These valves are used on gas bleeder lines. Bleeding is the process of releasing pressure from pressurized equipment or wells using a pipe.

- Needle valves control the airflow to cylinders that control piston speed.

- They are also employed in automated combustion control systems to regulate fuel flow.

- Needle valves monitor the flow of gas like propane in a system. A propane needle valve shuts off the flow accurately and/or controls the flow rate, thereby keeping a check on the burn rate for several applications.

- Needle valves for air and other gasses are typically made from brass, bronze, stainless steel, or metal alloys and may also be anodized to provide corrosion resistance.

Steam needle valves

Steam traps and steam locking

Heating processes involving steam use latent heat and transfer it to a product. Latent heat is the energy needed by water molecules to break their bonds and form steam. Steam condensate cannot work like steam for heating purposes and needs to be drained out. Steam traps are self-contained valves that automatically channel the condensate from a steam-containing enclosure (by sensing the difference in densities) while blocking steam.

At times, steam enters the valve ahead of the condensate and shuts the trap valve, impeding condensate discharge. Due to this, the steam-heated processes may experience sudden temperature drops even when the system appears to be working properly.

Figure 3: Steam trap used to remove condensate from a pipe

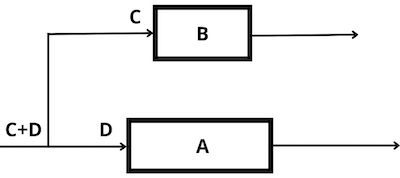

An external bypass line can be installed for steam to bypass the steam trap. Steam blocked by the steam trap (Figure 4 labeled A) flows through the bypass line where a needle valve (Figure 4 labeled B) lets the steam (Figure 4 labeled C) pass through. The condensate (Figure 4 labeled D) passes through the steam trap, from where it is drained away.

If the steam trap has a built-in venting feature, a needle valve can be attached internally to the trap to release the trapped steam to an outlet. Needle valves for steam applications are generally made of stainless steel.

Figure 4: Needle valve used to bypass steam from a steam trap: Steam trap (A), Needle valve (B), Steam (C), and condensate (D).

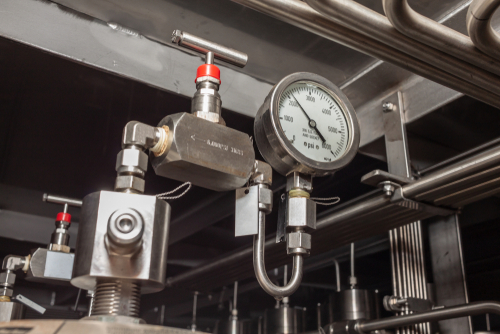

Needle valves for pressure gauge and flow meter

Needle valves are primarily used in small systems such as fuel regulation or instrumentation, where the ability to control the fluid flow precisely and repeatedly is highly desirable. Also, needle valves are typically used to shut off a pressure gauge (Figure 5). The valve regulates the flow and protects pressure gauges from abrupt pressure surges of liquids and gasses.

Needle valves are commonly used in flow metering applications, mainly when a calibrated low flow rate must be preserved for a long time, like the idle fuel flow in a carburetor.

Figure 5: Needle valve attached to a pressure gauge

FAQs

What is the advantage of a needle valve?

Needle valves provide a slow and precise control over the amount of fluid that can pass through the valve.

What is a needle valve used for?

A needle valve regulates fluid flow through an appliance or system. The valve includes a small plunger with a shape similar to a needle with a tapered end.

What is a needle valve used for in pneumatic circuits?

A needle valve is used to reduce the flow rate in a pneumatic circuit.