Car Wash Solenoid Valves

Figure 1: Automatic car wash system

Solenoid valves in car wash systems regulate the flow of water, detergents, and other cleaning agents, playing a vital role in automated car wash operations. These electrically operated valves ensure precise and efficient fluid management, facilitating the different stages of the wash process. Designed to withstand harsh environments, these valves are crucial for maintaining consistent performance and reliability. This article examines the function of solenoid valves in car wash systems, important factors to consider when selecting them, and their maintenance requirements.

Table of contents

- Solenoid valves for car wash systems

- Working of a car wash system

- Car wash solenoid valve selection criteria

- Maintenance of solenoid valves for car wash systems

View our online selection of car wash solenoid valves!

Solenoid valves for car wash systems

Solenoid valves are essential components in car wash systems, responsible for controlling the flow of various cleaning agents and chemicals. Their functions are:

- Soap and wax metering: Solenoid valves ensure the precise amount of soap and wax is dispensed for each car, optimizing cleaning and finishing processes.

-

Low-pressure functions:

- Foam brush: They control the flow of foam to brushes, ensuring even and effective application.

- Tire cleaner: Solenoid valves manage the distribution of tire cleaning solutions by being strategically placed and controlled to open and close at precise times, directing the flow to specific areas for thorough cleaning.

- Presoak: They regulate the application of presoak solutions, which help loosen dirt and grime before the main wash.

Read our solenoid valve overview article for more details on the design and working of solenoid valves.

Working of a car wash system

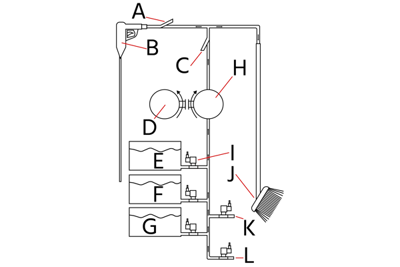

Figure 2: Working of a car wash system: Osmotic water (A), lance (B), compressed air (C), electric motor (D), wax (E), foam (F), detergent (G), pump (H), solenoid valve (I), brush (J), hot water (K), and cold water (L)

Figure 2 shows a car wash system. The car wash system operates through a user-selected cleaning cycle on a control panel, utilizing two primary tools: a lance (washing gun) and a brush. The lance (B) shoots water or shampoo under pressure, while the brush (J) scrubs the vehicle with liquid detergent. During the shampooing cycle, solenoid valves regulate the flow of cold and hot water, detergent (G), foam (F), and wax (E), mixing them with water. An electromechanical pump (H) creates a vacuum to draw in the mixture and then pumps it back at high pressure (80 bar). The mixture is further aerated before reaching the brush for effective application. The lance can dispense either water or shampoo based on the selected cycle. For rinsing, the system uses softened and osmotic water to avoid limescale stains on the vehicle.

Car wash solenoid valve selection criteria

- Valve type:Normally closed solenoid valves are commonly used in car wash systems because they prevent fluid flow when the system is off, ensuring safety and control.

- Number of ports: 2-way and 3-way solenoid valves are commonly used in car wash systems. 2-way valves are ideal for simple on/off control of a single fluid stream, like, controlling the flow of water to the rinse stage, managing the flow of detergent to the brushes, and turning on/off the supply of wax. 3-way valves have three ports and can be used to switch between different fluid pathways or mix fluids. For example, switching between soap and wax applications, directing water to different stages, such as pre-soak and rinse, and mixing water with detergent before application

- Pressure, voltage, and power requirements: Ensure the solenoid valves can handle the car wash system's operating pressure to prevent failure and ensure reliability. Additionally, choose valves that match the system's voltage and power supply (often 12V or 24V) for compatibility with the existing electrical setup.

- Response time: Quick response time is crucial for immediate fluid control during different stages of the wash process, enhancing efficiency and effectiveness.

- Materials:The valve housing is typically made of stainless steel, brass, or plastic. Stainless steel offers high corrosion resistance and durability, ideal for harsh chemicals and long-term use. Brass has good corrosion resistance and is cost-effective, suitable for water and cleaning solutions. Plastic (e.g., PVC, Nylon) is lightweight and chemical-resistant, used in low-pressure applications and for cost savings. Also, the solenoid valves should have excellent sealing properties to prevent leaks. EPDM (Ethylene Propylene Diene Monomer) has excellent resistance to water, steam, and detergents. Suitable for both hot and cold water applications. FKM (Fluoroelastomer, Viton) has superior chemical resistance, especially to oils and aggressive chemicals. Ideal for harsh chemical environments. NBR (Nitrile Butadiene Rubber) has good resistance to oils and certain chemicals. Cost-effective but less resistant to ozone and UV. PTFE (Polytetrafluoroethylene, Teflon) has exceptional chemical resistance and high temperature tolerance. Suitable for aggressive chemicals and high-pressure applications. Read our chemical resistance chart for more details on the compatibility of different materials with various media.

- Flow control: Car wash systems often need precise flow rate control for stages like pre-soak, rinse, and wax. This ensures tailored fluid delivery for each stage. Choose valves with adjustable flow control features. For instance, a solenoid valve with adjustable flow control can regulate the amount of pre-soak solution applied, ensuring effective dirt loosening without waste. Similarly, during the rinse stage, the valve can adjust water flow for thorough rinsing without excessive water use.

- Automation compatibility: Ensure the solenoid valves can be easily integrated into the control system, such as PLCs or microcontrollers.

- Maintenance and serviceability: Evaluate the ease of maintenance and the availability of spare parts to minimize downtime and maintenance costs. Choose car wash solenoid valves that are easy to service and have readily available parts.

Figure 3: 3-way stainless steel solenoid valve switch between different fluid pathways or mix fluids

Maintenance of solenoid valves for car wash systems

Solenoid valves in car wash systems are heavily used, and even minor defects can halt operations. Reliable performance requires high-quality parts and a strict maintenance schedule. Regular inspections and periodic part replacements, especially for high-usage systems, can extend valve lifespan and reliability. Key components like the plunger, spring, and coil should be monitored and replaced as needed.

Common issues with car wash solenoid valves

- Dirt in the valve: Dirt can clog channels or dirty the sealing surface, causing poor performance. Clean the valve by disconnecting the power, removing the coil, and washing internal parts with water or mild soap. Install a filter in the supply line to prevent future issues.

- Coil burnout: Coil failure often results from overheating, moisture, or dirt blocking the plunger. Replace the coil if it burns out, ensuring the new coil has an IP65 or higher protection rating.

- Corrosion: Corrosion is common in car wash environments. Use stainless steel valves for longevity, though brass can be used for clean water or air. Clean surface corrosion with mild soap, but replace heavily corroded valves to prevent breakage.