Butterfly Valve vs Ball Valve

Figure 1: A butterfly valve (left) and a ball valve (right)

Both butterfly and ball valves offer unique benefits, so choosing between them in certain processes is not hard. However, it can be problematic when a process requires valve characteristics that both valves have. This article delves into a deeper understanding of the butterfly valve vs. ball valve in order to pick the correct valve.

- Butterfly valves: More suitable for larger pipe diameters but also available at smaller diameters. They are often used in systems where cost-effectiveness for large valves and the ability to handle large volumes of fluid with minimal pressure drop are important.

- Ball valves: Ideal for smaller pipe diameters and applications that require a tight shut-off and minimal leakage. They are well-suited for high-pressure and high-temperature environments, as well as situations where precise flow control is necessary.

Table of contents

- Butterfly and ball valve similarities

- Understanding butterfly valves

- Understanding ball valves

- Butterfly and ball valve differences

- Sanitary applications

- FAQs

Check out Tamesons selection of butterfly valves and ball valves!

Butterfly and ball valve similarities

Butterfly and ball valves are among the simplest and most versatile valve types, widely used for controlling fluid flow in various settings. Here are some key features of these valves:

- Operation mechanism: Both are quarter-turn rotary valves, requiring a 90° turn to move from fully closed to fully open.

- Applications: Suitable for domestic, commercial, and industrial use, handling various temperatures and pressures.

- Control options: Can be operated manually or with electric or pneumatic actuators.

- Cost and maintenance: They are relatively inexpensive, easy to maintain, and reliable.

- Durability: These valves typically have a longer life expectancy than other valves.

These similarities do not mean the valves are interchangeable in all process functions. Instead, they suggest we need to examine the valves' characteristics and determine which applications to use each valve in.

Understanding butterfly valves

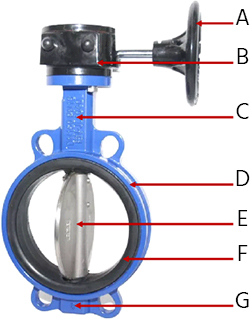

Figure 2: Components of a butterfly valve: lever (A), stem (B), seal (C), disc (D), and body (E).

A butterfly valve has a disc (Figure 2 labeled D) driven by a lever (Figure 2 labeled A). When closed, the disc is perpendicular to the flow direction. A seal (Figure 2 labeled C) sits within the valve body (Figure 2 labeled E) and ensures a tight closure with the valve disc, and there is a near-linear relationship between the butterfly valve's stem (Figure 2 labeled B) position and flow rate. The butterfly valve can be controlled manually, electrically, or pneumatically.

One of the key advantages of butterfly valves is that they are generally more cost-effective at large diameters due to having fewer parts and being relatively lightweight, requiring less support. Large diameter butterfly valves at high-pressure differences can be difficult to open, necessitating a bypass valve to balance pressure before opening.

There is a pressure drop across the butterfly valve as the disc remains inside the flow even when fully open. Butterfly valves are typically ON/OFF valves and are not suitable for precise fluid flow control.

Read our articles on high-performance butterfly valves and other butterfly valve designs to learn more.

Understanding ball valves

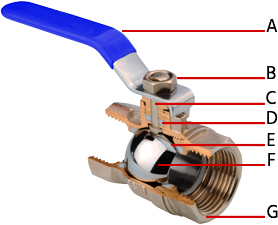

Figure 3: Components of a ball valve: handle (A), shaft (B), seat (C), ball (D), body (E).

A ball valve has a hollow spherical ball (Figure 3 labeled D) that is pivoted at one or both ends. The top end of the ball is attached to a shaft (Figure 3 labeled B), which is rotated by a handle (Figure 3 labeled A) to change the valve position to open or close. When fully open, the hole in the ball lies parallel with the pipe flow direction. The ball rests on a seat (Figure 3 labeled C) inside the valve body (Figure 3 labeled E).

A ball valve can be controlled manually, electrically, and pneumatically. Ball valves can also have three-way flow directions in a T or L shaped bore. The bore in a ball valve can vary from smaller than the pipe diameter (reduced port or reduced bore), a size equal to the pipe diameter (full port), or a V-port design. The design of the ball affects flow characteristics.

Ball valves have zero leakage when fully closed, as the fluid pressure upstream of the valve pushes the ball against the seal, ensuring a positive shutoff position. Ball valves will easily open at a high-pressure difference on both sides of the valve and do not require a pressure-balancing bypass.

Butterfly and ball valve differences

Though butterfly valves and ball valves share some similarities, they have distinct differences that give each an advantage in specific applications. Table 1 compares the valve characteristics of each valve and their advantages over the other.

Table 1: Ball valve vs butterfly valve

| Butterfly valve | Ball valve | |

| Weight | Lighter weight, especially at larger pipe diameters | Very heavy at larger pipe diameter and may require support |

| Installation space | Requires narrower space between pipe ends | Requires more space between pipe ends |

| Size | Suitable for larger pipe diameters (up to DN 700) because lighter than ball valve | Better suited for smaller pipe diameters (up to DN 100) |

| Leakage | Not as reliable as ball valve at high pressure. Excellent seal at low pressure. | Provides a tight seal even at a high-pressure difference. Excellent seal at low pressure. |

| Cost | Less expensive at higher diameters (DN 100 and above) | Less expensive at lower diameters (Below DN 100 or 4 inches) |

| Flow control | Suitable for ON/OFF control and can be used for proportional control. | Functions well for both ON/OFF. V-port ball valves can modulate flow. |

| Flow restriction | Valve disc restricts flow creating a pressure drop. | Full-port ball valves have no pressure drop. |

| Connection style | It has a flange style with a lug or wafer design | A wide array of connection types with threads or flanges |

Sanitary applications

In sanitary applications, such as those in the food, beverage, and pharmaceutical industries, maintaining hygiene and preventing contamination are critical.

Butterfly valves

- Material: Choose stainless steel for corrosion resistance and hygiene.

- Design: Look for smooth, crevice-free designs with food-grade elastomer or PTFE seats for a tight seal.

- Cleaning: Ensure they are easy to disassemble or compatible with CIP (Clean-In-Place) systems for efficient cleaning.

Ball valves

- Material: Opt for stainless steel to meet hygiene standards.

- Full-bore design: This minimizes pressure drop and allows for easy cleaning, with smooth internal surfaces.

- Sealing: Use sanitary seals made from PTFE or other food-grade materials to prevent contamination.

Pigging

Pigging is a process used to clean pipelines by sending a device called a "pig" through them. This is important for removing debris and ensuring pipeline efficiency and safety.

- Butterfly valves: Generally not suitable for pigging because the disc obstructs the flow path, hindering the pig's movement.

- Ball valves: Full-bore ball valves are ideal for pigging. They provide an unobstructed path, allowing the pig to pass through easily and ensuring effective cleaning and maintenance of the pipeline.

FAQs

What are the advantages of a butterfly valve?

Butterfly valves are compact, cost-effective, and suitable for large diameters, offering quick operation and minimal pressure drop.

How does a ball valve differ from a butterfly valve?

A ball valve uses a rotating ball to control flow, offering tight sealing, while a butterfly valve uses a rotating disc, ideal for throttling and large diameters.

Why choose large-diameter butterfly valves?

Large-diameter butterfly valves are chosen for their lightweight design, cost-effectiveness, and efficiency in handling high flow rates.