Tap & Die Standards

Figure 1: Tap and Die Set

Taps and dies are cutting tools used to create threads on components such as screws, bolts, nuts and to create a threaded hole to screw components into. This article covers common standards for these products. If you are looking at how to use them, please read our tap and die set article. For more information on sizes and drilling holes for tapping a thread, see our tap drill size chart.

Below are the various standards that taps, dies, and the different related tools need to abide by. Use our table of contents to navigate between the respective standards.

Tamesons selection of thread cutting tools

DIN 13-1 to DIN 13-52

- DIN 13-1: ISO general purpose metric screw threads - Part 1: Nominal sizes for coarse pitch threads; nominal diameter from 1 mm to 68 mm

- DIN 13-2: ISO general purpose metric screw threads - Part 2: Nominal sizes for 0.2 mm, 0.25 mm and 0.35 mm fine pitch threads; nominal diameter from 1 mm to 50 mm

- DIN 13-3: ISO general purpose metric screw threads - Part 3: Nominal sizes for 0.5 mm fine pitch threads; nominal diameter from 3.5 mm to 90 mm

- DIN 13-4: ISO general purpose metric screw threads - Part 4: Nominal sizes for 0.75 mm fine pitch threads; nominal diameter from 5 mm to 110 mm

- DIN 13-5: ISO general purpose metric screw threads - Part 5: Nominal sizes for 1 mm and 1.25 mm fine pitch threads; nominal diameter from 7.5 mm to 200 mm

- DIN 13-6: ISO general purpose metric screw threads - Part 6: Nominal sizes for 1.5 mm fine pitch threads; nominal diameter from 12 mm to 300 mm

- DIN 13-7: ISO general purpose metric screw threads - Part 7: Nominal sizes for 2 mm fine pitch threads; nominal diameter from 17 mm to 300 mm

- DIN 13-8: ISO general purpose metric screw threads - Part 8: Nominal sizes for 3 mm fine pitch threads; nominal diameter from 28 mm to 300 mm

- DIN 13-9: ISO general purpose metric screw threads - Part 9: Nominal sizes for 4 mm fine pitch threads; nominal diameter from 40 mm to 300 mm

- DIN 13-10: ISO general purpose metric screw threads - Part 10: Nominal sizes for 6 mm fine pitch threads; nominal diameter from 70 mm to 500 mm

- DIN 13-11: ISO general purpose metric screw threads - Part 11: Nominal sizes for 8 mm fine pitch threads; nominal diameter from 130 mm to 1000 mm

- DIN 13-12: ISO general purpose metric screw threads - Part 12: 1 to 300 mm diameter coarse and fine pitch threads Selected diameters and pitches

- DIN 13-13: ISO general purpose metric screw threads - Part 13: Selected sizes for screws, bolts and nuts from 1 to 52 mm screw thread diameter and limits of sizes

- DIN 13-19: ISO general purpose metric screw threads - Part 19: Nominal profiles

- DIN 13-20: ISO general purpose metric screw threads - Part 20: Limits of sizes for coarse pitch threads with the preferred tolerance classes; nominal sizes from 1 mm to 68 mm

- DIN 13-21: ISO general purpose metric screw threads - Part 21: Limits of sizes for fine pitch threads with the preferred tolerance classes; Nominal diameter from 1 mm to 24.5 mm

- DIN 13-22: ISO general purpose metric screw threads - Part 22: Limits of sizes for fine pitch threads with the preferred tolerance classes; Nominal diameter from 25 mm to 52 mm

- DIN 13-23: ISO general purpose metric screw threads - Part 23: Limits of sizes for fine pitch threads with the preferred tolerance classes; Nominal diameter from 53 mm to 110 mm

- DIN 13-24: ISO general purpose metric screw threads - Part 24: Limits of sizes for fine pitch threads with the preferred tolerance classes; Nominal diameter from 112 mm to 180 mm

- DIN 13-25: ISO general purpose metric screw threads - Part 25: Limits of sizes for fine pitch threads with the preferred tolerance classes; Nominal diameter from 182 mm to 250 mm

- DIN 13-26: ISO general purpose metric screw threads - Part 26: Limits of sizes for fine pitch threads with the preferred tolerance classes; Nominal diameter from 252 mm to 1000 mm

- DIN 13-28: ISO general purpose metric screw threads - Part 28: Coarse and Fine Screw Threads from 1 to 250 mm Screw Thread Diameter; Root Cross-sections, Tensile Stress Cross-sections and Pitch Angles

- DIN 13-50: ISO general purpose metric screw threads - Part 50: Combination of tolerance classes for formed internal screw threads

- DIN 13-51: ISO general purpose metric screw threads - Part 51: External screw threads for transition fits (former: screw threads for interference fit); tolerances, limit deviations, limits of sizes

- DIN 13-52: ISO general purpose metric screw threads - Part 52: Multi-start thread tolerances and deviation of profile

DIN 225

DIN 225 covers the specifications for die stocks.

Figure 2: A die stock

DIN 228-1 and ISO 296

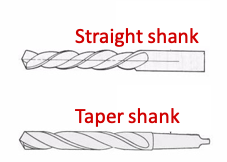

DIN 228-1 and ISO 296 defines the taper of shanks (morse tapers and metric tapers).

Figure 3: Straight vs taper shank

DIN 228-2

DIN 228-2 defines socket sizes and specifications of taper sockets (morse tapers and metric tapers).

Figure 4: Taper socket

DIN 351/UNC

DIN 351/UNC is the standard for short-hand taps.

Figure 5: Set of short-hand taps

DIN 352

DIN 352 covers sets of 3 taps for metric coarse ISO-threads M1 to M68. It has nominal sizes of 0.25 – 6.0 mm.

Figure 6: Hand tap set of 3 pieces

DIN 371

DIN 371 is the standard for machine taps with reinforced shank for coarse pitch metric ISO-threads M1 to M10 and fine pitch metric ISO-threads M1 × 0.2 to M10 × 1.25. L1 ranges from 40 – 100 mm, L2 from 4 to 15 mm, and L3 from 10 to 32 mm.

Figure 7: Machine taps with dimensions

DIN 374

DIN 374 is the standard for machine screwing taps for fine pitch metric ISO-threads M3 × 0.2 to M52 × 4. L1 ranges from 80 – 225 mm and L2 from 10 to 45 mm.

DIN 376

DIN 376 covers machine screwing taps for coarse pitch metric ISO-threads M1.6 to M68.

DIN 1814

DIN 1814 defines the size and specifications for adjustable tap wrenches.

Figure 8: An adjustable tap wrenches

DIN 2181

DIN 2181 covers sets of 2 taps for metric fine ISO-threads M1 × 0.2 to M52 × 4. M1 and M52 refer to thread diameter/size in millimeters, while 0.2 and 4 refer to thread length in inches. According to the DIN standards committee, “This standard applies to sets of 2 taps consisting of pre-cutters (V) and finish cutters (F), which are intended for the production of metric ISO fine threads according to DIN 13-2 to DIN 13-9”.

Figure 9: Hand tap set of 2 pieces

DIN EN ISO 4231

DIN EN ISO 4231 covers hand and machine-operated circular screwing dies for parallel pipe threads - G series (ISO 4231:2016).

DIN 5157 (former DIN 253)

DIN 5157 covers sets of 2 taps for pipe threads G 1/16 to G 4 and Rp 1/16 to Rp 4. According to the DIN standards committee, “The standard applies to inserts in sets of 2 taps consisting of the first tap and bottoming tap used for producing internal pipe threads where pressure-tight joints are not made on the threads (symbol G) according to DIN EN ISO 228-1 and Whitworth pipe threads for threaded pipes and fittings (symbol Rp) according to DIN EN 10226-1”.

Figure 10: Set of thread cutters

DIN EN 22568

DIN EN 22568 covers hand and machine-operated circular screwing dies and hand-operated die stocks (ISO 2568:1988).

Figure 11: A circular screw die

DIN 24231 (former DIN 5158)

DIN 24231 covers the specifications for round dies.

Figure 12: Round die

ISO 68-1

ISO 68-1 is the standard for general-purpose screw threads, basic profile, and metric screw threads.

ISO 261

ISO 261 covers the specification list of preferred combinations of outer diameter and pitch for ISO metric screw threads. ISO 262 is a subset of ISO 261 with a shorter list.

ISO 965

ISO 965 is the standard for general-purpose metric screw threads and their associated tolerances. The standard consists of the following subsections:

- ISO 965-1: Principles and basic data

- ISO 965-2: Limits of sizes for general purpose external and internal screw threads

- ISO 965-3: Deviations for constructional screw threads

- ISO 965-4: Limits of sizes for hot-dip galvanized external screw threads to mate with internal screw threads tapped with tolerance position H or G after galvanizing

- ISO 965-5: Limits of sizes for internal screw threads to mate with hot-dip galvanized external screw threads with a maximum size of tolerance position before galvanizing

ASME/ANSI B94.9

ASME/ANSI B94.9 is the standard for taps, cut, and ground threads. Handles designs of taps, nomenclature, definitions, marking system, dimensions, tolerances for stand straight thread, pipe-taper thread, pipe-straight thread, pulley, screw thread insert, and thread forming taps.