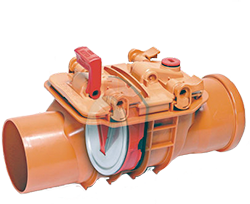

Sewer Check Valve

Figure 1: Sewer check valve

Municipal sewers can back up during heavy rain, flooded streets, or rapid snowmelt. A sewer check valve, also known as a backwater or backflow check valve, stops sewage flowing from the municipal sewer system into a residential or commercial building. If the building has a basement, that will be the first area flooded. If the backflow is severe enough, sewage can back up into plumbing fixtures like toilets, sinks, and showers.

Municipal sewers can back up during heavy rain, flooded streets, or rapid snowmelt. A sewer check valve, also known as a backwater or backflow check valve, stops sewage flowing from the municipal sewer system into a residential or commercial building. If the building has a basement, that will be the first area flooded. If the backflow is severe enough, sewage can back up into plumbing fixtures like toilets, sinks, and showers. Having a properly installed and functioning sewer check valve can help avoid costly repairs.

Table of contents

- Check valves

- Sewer check valve design and function

- Sewer check valve installation and maintenance

- Sewer check valve material

- FAQs

View our online selection of check valves!

Check valves

A check valve allows flow in one direction and blocks flow in the other. These valves can be normally open or normally closed. A normally open check valve closes when the pressure from backflow exceeds a specific limit and then opens again when pressure diminishes. A normally closed check valve works similarly but is dependent on the pressure coming from the input side of the valve. Several different types of check valves perform this function. Learn more by reading our check valve article!

Sewer check valve design and function

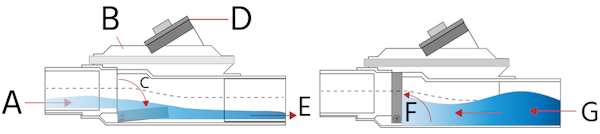

Figure 2: A normally open sewer check valve with inlet and outlet ports (A, E), a clear top for easy inspection (B), and a cleanout (D). The valve has a built-in drainage slope (C). Backflow (G) lifts the flapper into the closed position (F).

Different types of sewer check valves are suitable for different applications, but the typical design uses a flapper that can be normally open or normally closed. The normally open design uses floaters which are attached to the flapper. As seen in Figure 2, wastewater flows into the valve (Figure 2 labeled A), down a built-in drainage slope (Figure 2 labeled C) and out into the municipal sewer system (Figure 2 labeled E). The valve has a clear top which allows for easy inspection (Figure 2 labeled B) and a cleanout (Figure 2 labeled D) to easily clean the valve. When backflow begins (Figure 2 labeled G), the floaters rise slightly, lifting the flapper, which allows the backflow to flow under the flapper and further lift it into the closed position (Figure 2 labeled F). The pressure from the backflow keeps the gate closed.

Other types of sewer check valves are:

- Dual plate check valves: These are sturdier and suitable for high-rise, urban, and industrial water supply drainage systems.

- Plug check valve: This valve has a broader body and cap. This design makes it easier to access and maintain the inside of the valve body without removing the valve from the pipeline.

Determining the correct type of check valve for a sewer drainage system may be as simple as looking up local regulations. The answer is typically found by searching online for the following terms in connection to a specific municipality:

- Backwater valve

- Sewer and wastewater management

- Check valve

- Sewer backup

- Flooding

A check valve on a sewer line is for temporary use. It does not stop 100% of backflow. Instead, it maintains a low backflow volume as the municipal sewer system reverts to normal operating conditions. Outside of extreme cases, such as massive floods, a sewer check valve is likely enough to protect property from sewage damage. A floodgate valve is a much more expensive option to stop flooding during extreme cases.

Sewer check valve installation and maintenance

Sewer check valve installation typically occurs during construction but can happen in existing buildings as a preventative measure against flooding. It should be installed horizontally. A licensed and experienced plumber should install a sewer check valve. The cost of making a mistake during installation far exceeds hiring someone to do it the right way. The following is what to expect during the installation process.

- Sewer trap: The first thing to determine is if the main sewer line leading from the house has a sewer trap (also known as a house trap). The house trap is a curved pipe that always holds water, which acts as a barrier against fumes backflowing from the municipal sewer system. If there is a sewer trap, install the sewer check valve on the street side of the trap. Doing this will help stop liquid backflow from washing out the trap, allowing the gaseous fumes to enter the building’s plumbing system.

- Sewer check valve installation point: Next, there is a question as to whether to install the sewer check valve into the main sewage line or not. If a single family occupies the premises, installation on the main sewage pipe may be acceptable. However, if multiple units are within the premises, installation on the main sewage pipe is likely not permissible. When backflow comes from the municipal sewer system, whoever has access to the basement or lowest plumbing fixture will be the first to notice the issue. However, this does not mean that everyone in the multiple-unit premises will know there is an issue. If the sewer check valve is closed to stop backflow, residents in other units may keep running water. This water will not enter the main sewer pipe and will flood out of the building's lowest fixtures. Therefore, install the sewer check valve to the pipe that branches off from the main sewer pipe to the basement drain or lowest plumbing fixture.

Sewer check valve maintenance

Maintaining sewer check valves is essential to ensuring that they properly operate when needed. These valves should be accessed and cleaned about twice per year on average. If wastewater from the premises contains anything that can build up quickly, such as grease, then more frequent cleaning may be necessary. Clean the sewer check valve of any build-up that stops the valve's flapper from fully closing. While cleaning the valve, take the opportunity to check the valve's o-ring for corrosion.

Sewer check valve material

Sewer check valves are typically made of PVC, ABS, or cast iron. PVC and ABS are both plastics. The obvious difference between them is that PVC is usually white and ABS is black. While PVC is more flexible, ABS is sturdier. Finally, connecting ABS sewer check valves to piping requires special cement for ABS, whereas PVC requires primer and cement.

PVC and ABS sewer check valves are both suitable for residential sewer systems. Cast iron sewer check valves may be required for industrial applications requiring stronger valves and high-temperature resistance.

Read our chemical resistance guide for more details on the compatibility of materials with different media.

FAQs

What is a sewer check valve?

A sewer check valve is installed in a building's sewer pipe that connects to the municipal sewer system. The valve stops backflow and flooding from a backed-up municipal sewer system.

Is a backwater valve necessary for a home?

Whether or not a backwater valve is necessary for a home depends on whether or not the home connects to the municipal sewer system. If so, then yes. If the home uses a septic tank, then no.