Set Screw Point Type Selection

Figure 1: Set screws offer strong connections without nuts.

The selection of set screw types, such as cup, cone, flat, dog, half dog, or knurled cup point, depends on the requirements for grip strength, the need to minimize surface damage, and whether the connection should be permanent or adjustable. This article provides an overview of the various point types and guidance on selecting between them.

Table of contents

What are set screws used for

Set screws are fastening devices that use compressive force to secure one object within another. These fasteners are inserted into threaded holes on the mating part. When tightened, the screw's point makes contact with the surface of the mating part. Set screws are commonly used in mechanical applications to affix gears, collars, or pulleys to a shaft, ensuring that the rotational motion of the shaft is imparted to the attached components.

Set screw point types

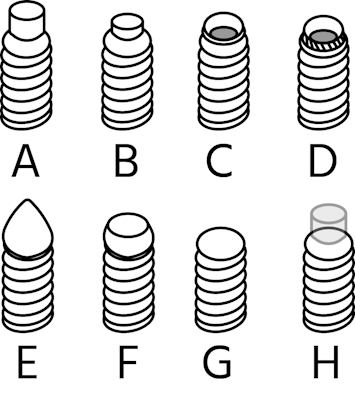

Figure 2: Dog point (A), half-dog point (B), cup point (C), knurled cup point (D), cone point (E), flat point (F), oval point (G), and nylon point (H)

Dog point set screw

Dog point set screws (Figure 2 labeled A) have a cylindrical extended tip that fits into a hole or slot to keep parts aligned. The extended tip is typically as long as the screw's diameter. They are used in applications where the set screw will mate into a predrilled hole. A common application for dog point set screws is with set screw collars, which locate components on a shaft, such as bearings.

Half dog point set screw

Half dog point set screws (Figure 2 labeled B) have an extended tip half as long as a dog point's tip, so approximately as long as half of the screw's diameter. These set screws are used for applications where the extended tip must be shorter to prevent the tip from interfering with machine components, such as gears or pulleys.

Cup point set screw

Cup point set screws (Figure 2 labeled C) are the most commonly used type because of their versatility. These set screws offer a strong grip and are used in applications requiring the set screw to dig into the mating part. Common applications are securing machine components onto shafts, such as collars, gears, and knobs. The cup provides enough grip without damaging the shaft.

Knurled cup point set screw

Knurled cup point set screws (Figure 2 labeled D) are similar to cup point set screws. However, the surface that contacts the mating part is knurled. This helps the screw point bite into the mating part. Knurled set screws are used in heavy vibration applications like motors or machinery.

Cone point set screw

Cone point set screws (Figure 2 labeled E) are also known as conical point set screws. These set screws have a sharp, pointed end that provides high holding power because the point deeply penetrates the mating part. These screws are typically used for permanent applications, such as setting a machine tool in relation to a workpiece or aligning gears to a shaft.

Flat point set screw

Flat point set screws (Figure 2 labeled F) have a flat end that presses flat against the surface of the mating part, not biting into it. These set screws are used when frequent adjustment is needed or when the point must be flush against the surface. They are used to adjust a collar on a shaft or when it needs to be repositioned without damaging the shaft.

Oval point set screw

Oval point set screws (Figure 2 labeled G) have a concave, rounded, oval-shaped point that decreases surface damage caused by the point. Like flat point set screws, oval point set screws are used when frequent readjustment is necessary. Their point shape allows the screw point to press against mating surfaces at slightly different angles.

Nylon tip set screw

Nylon-tipped set screws (Figure 2 labeled H) provide a secure grip without marking or damaging the surface of the mating part. This is used in applications where the mechanical properties of metal tips are not desirable, such as electronic applications.

Selecting a set screw point type

Use the following criteria to determine which type of set screw point to use for a specific application:

-

Material hardness: The hardness of the materials being fastened will affect the choice of point type. Softer materials may require less aggressive points to prevent damage, while harder materials may need sharper points for better grip.

- Hard material: cup, knurled cup, and cone points

- Soft material: oval and flat points

-

Application requirements: Consider whether the application requires frequent adjustments, permanent setting, or specific alignment features.

- Frequent adjustments: flat and oval point

- Permanent: Cone and knurled point

- Specific alignment: dog and half dog point

-

Surface damage: If preventing damage to the shaft or mating part is important, choose a point type that minimizes surface indentation or deformation.

- Flat and oval point

- Vibration: In high-vibration applications, select a point type that resists loosening, such as a knurled cup point.

FAQs

Why are there different set screw point types?

Some point types can bite deeper into the material for a strong connection, whereas others do not and simply press against the surface, doing less damage.

How do I know what set screws to use?

Determine the set screw point for the application. Will the connection be permanent or adjustable, is surface damage OK or not, and what hardness is the material being joined?