How to Use a Rivet Gun

Figure 1: A manual rivet gun and pop rivets.

A rivet gun is a simple tool to efficiently install rivets, which fastens two separate materials together. This efficiency makes rivet guns valuable tools in applications ranging from assembling furniture to building airplane wings. This article examines the types of rivet guns and how and when to use them.

Table of contents

- What is a rivet gun?

- Rivet gun advantages and disadvantages

- What are rivet guns used for?

- Selecting a rivet

- Riveting without a rivet gun

- FAQs

View our online selection of pneumatic rivet guns!

What is a rivet gun?

A rivet gun is a machine that efficiently installs rivets. There are several types of rivet guns, but the three general categories are manual, pneumatic, and electric. This section briefly describes each type's similar components and advantages and disadvantages. Learn more about each type by reading our manual, pneumatic, and electric rivet gun articles.

Rivet gun components

Manual, electric, and pneumatic rivet guns have components that distinguish each from the other types. This section focuses on their similar components that allow the riveting process.

- Nose piece: A rivet gun user inserts rivet mandrels into the rivet gun’s nose piece. Within the nose piece is the jaw assemblage.

- Jaw assemblage: A rivet gun's jaw assemblage grips onto the mandrel of the rivet that inserts into the gun's nose piece. During operation, the jaws pull on the mandrel, deforming the other end of the rivet until the mandrel breaks off the rivet's body. When the mandrel breaks off, rivet deformation is complete, meaning the material is fastened at that point.

- Trigger mechanism: The rivet gun's trigger mechanism operates the rest of the gun's components. A finger can pull the trigger on a pneumatic and electric rivet gun. A manual rivet gun's trigger mechanism is the gun's two handles. The user holds the front handle in one hand and pushes the back handle towards the front handle to operate the tool.

Note: The above information discusses pop riveting since pop rivets are the most common. A later section will discuss other rivet types.

Rivet gun advantages and disadvantages

Manual, electric, and pneumatic rivet guns have the following advantages and disadvantages.

Table 1: Advantages and disadvantages of various rivet gun types

| Rivet gun type | Advantages | Disadvantages |

Manual |

Ready to operate without compressed air or electricity | Slowest operation speed |

| Inexpensive | Extensive use can injure a user’s hand | |

Electric |

Fast operation speed | Electricity source required |

| Adjust to control the power impacting the rivet | Expensive | |

Pneumatic |

Fast operation speed | Compressed air required |

| Lightweight | Regular lubrication required |

What are rivet guns used for?

The most common use for a rivet gun is to fasten two separate pieces of metal together. Riveting is also applicable with wood and plastic.

Metal

The following steps explain how to fasten two pieces of metal together with rivets.

- Align the two pieces in the position they should maintain after riveting.

- Drill holes that go through both pieces of metal at each rivet installation point.

- Use a drill bit that is slightly smaller than the rivet’s diameter. This ensures that the connection will hold when the rivet’s body expands.

- Insert the rivet’s mandrel into the rivet gun’s nose piece.

- Insert the rivet’s body into the pre-drilled hole.

- Operate the rivet’s trigger mechanism until the mandrel breaks off.

- It is typical to operate the trigger mechanism multiple times to break off the mandrel.

Wood

The riveting process with wood is similar in many ways to the metal process. There are two important differences to understand, though. First, riveting does not work with soft woods like cedar and pine: the rivets will split the wood. Second, to avoid splitting, use a high-speed carbide drill to pre-drill the holes the rivets will go through.

Plastic

The metal riveting process does not work with plastic because plastic is too soft to hold typical rivets. During operation, the rivet gun will likely pull the rivet body through the plastic before the mandrel breaks off. One solution is to use washers on the side of the fastened material that has the deformed rivet. However, if that side of the joining is inaccessible, glue on washers in advance. Finally, special rivets for plastic riveting are available. These rivets are made of aluminum. Also, the side of the rivet that deforms expands into three petals, which increases the surface area and prevents the rivet body from pulling through the plastic.

Selecting a rivet

Most of the information in the above sections explains how to install a pop rivet using a pop rivet gun since they are most common. There are many other rivet types worth noting, though, because choosing a rivet gun can depend on which type of rivet is chosen. The following information briefly explains other types of rivets.

- Solid rivet: Use a hammer or an air hammer to install a solid rivet.

- Split rivet: Use a split rivet setting tool or automatic feed rivet machine to install a split rivet.

- Blind rivet: Blind rivet is another name for pop rivet. Therefore, use a pop rivet gun to install a blind rivet.

- Friction lock rivet: A friction lock rivet is an early version of a blind rivet. Therefore, use a pop rivet gun to install a blind rivet.

- Self-piercing rivet: Use a self-piercing rivet gun to install a self-piercing rivet.

- Threaded rivet: Use a rivnut tool to install threaded rivets. This tool is similar to a pop rivet gun but has a threaded nose piece.

- Drive rivet: Use a hammer or air hammer to install a drive rivet.

- Semi-tubular rivet: Use a hammer or air hammer to install a semi-tubular rivet.

- Oscar rivet: An oscar rivet is similar to a pop rivet but has a hollow shaft in the body. Therefore, use a pop rivet gun to install an oscar rivet.

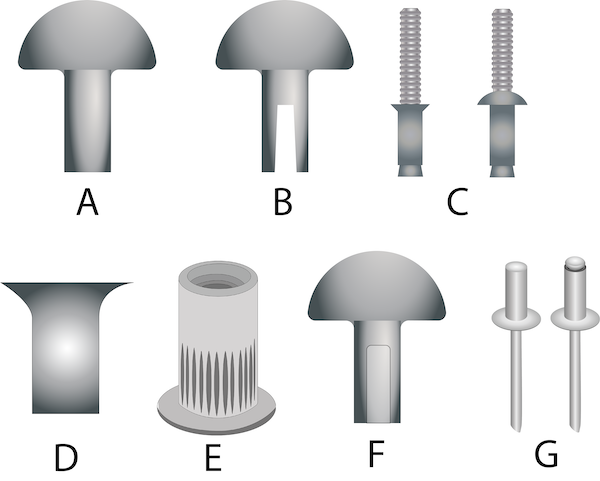

Figure 2: Rivet types: solid rivet (A), split rivet (B), friction lock rivet (C), self-piercing rivet (D), threaded rivet (E), semi-tubular rivet (F), and oscar rivet (G).

Riveting without a rivet gun

Simple DIY riveting projects are feasible without a rivet gun. A basic rivet is simply a metal shaft with a flanged end. To install this rivet, place it through a hole and secure the flanged end against the material. Use a hammer to deform the other end of the rivet, making it wider than the hole.

FAQs

Why would you use a rivet gun?

Using a rivet gun is an efficient way to install a rivet. Rivets are designed to fasten two pieces of material together permanently and tightly.

Do you have to drill a hole to use a rivet gun?

Before using a rivet gun to install a rivet, pre-drill holes through the material that will be fastened together. The rivets go through the holes and deform on one end to fasten the material together.