Introduction To The Pressure Equipment Directive

Figure 1: The Pressure Equipment Directive controls pressure equipment in the European Union.

The Pressure Equipment Directive (PED) controls pressure equipment with a maximum allowable pressure greater than 0.5 barg (7.2 psig) and the related pressure equipment's design, manufacturing, and conformity within the European Union. It is intended as quality assurance to ensure pressure equipment used in the European Economic Area is safe.

Note: PED is not intended for use in the United States. The ASME BPVC (American Society of Mechanical Engineers Boiler and Pressure Vessel Code) regulates the construction and design of pressure equipment in the US. This article deals with the Pressure Equipment Directive (PED) from the European Union.

Table of contents

What is the Pressure Equipment Directive (PED)?

Pressure equipment and pressure systems used inside the European Union must comply with the PED. A pressure equipment's hazard level must be assessed and classified into one of five categories under the PED based on their hazard level. These categories are:

- SEP: Sound engineering practice

- Category 1

- Category 2

- Category 3

- Category 4

Under these categories, SEP is the least hazardous, and Category 4 has the highest hazard levels involved. Quality assurance during design, manufacturing, and testing will be more extensive with increasing hazard levels. By the end of the quality assurance process, categories 1 to 4 will be marked with the CE mark. SEP products do not need this marking, nor may they be marked with the CE marking.

Those involved with quality assurance (such as process engineers) should follow the PED's methodology for classifying pressure equipment correctly. An overview of this methodology appears at the end of this guide. After determining whether the PED covers the equipment, the classification consists of six steps:

1) Identify the type of pressure equipment.

There are six types of pressure equipment: vessel, steam generator, piping, safety accessories, pressure accessories, and assemblies. For more information read our PED and CE markings article.

2) Determine the condition of the fluid within the equipment

If the fluid's vapor pressure at the maximum allowable temperature is more than 0.5 bar above atmospheric pressure, it is treated as a gas. Other than that, it is treated as a liquid.

3) Determine the hazard group

There are two hazard groups for gases and liquids.

- Group 1: Group 1 designates media as hazardous. Group 1 hazardous media are all media that are either explosive, extremely flammable, highly flammable, flammable, very toxic, toxic, or oxidizing.

- Group 2: Group 2 covers all other media. Note media that can be dangerous, but not hazardous (i.e. steam) is categorized as Group 2 due to this.

4) Select the appropriate hazard category chart

The fourth step in accessing the correct category for pressure equipment is choosing the correct hazard Category chart. Nine charts are available for each possible combination of equipment type, fluid state, and fluid group.

5) Maximum allowable pressure and equipment dimension

Defining the maximum allowable pressure and defining the dimensions of the equipment is the fifth step when determining the PED Category. Maximum allowable pressure is the maximum pressure that the equipment is designed to withstand as specified by the manufacturer. Each type of equipment has a unique definition. A vessel or steam generator is defined by its volume in liters. A piping system's defining dimension is the nominal size of its components expressed in millimeters. This is usually the pipe's nominal diameter.

6) Determine the PED hazard Category

The sixth and final step is using the chart in Table 1 to find out the hazard category. First, it is necessary to determine the chart. To do this, take the equipment type, fluid type, and hazard group.

Table 1: Chart to determine the hazard category

| Equipment | Fluid state | Fluid hazard group | Chart to use |

| Vessel | Gas | 1 | 1 |

| Vessel | Gas | 2 | 2 |

| Vessel | Liquid | 1 | 3 |

| Vessel | Liquid | 2 | 4 |

| Steam generator | 0 | 0 | 5 |

| Piping | Gas | 1 | 6 |

| Piping | Gas | 2 | 7 |

| Piping | Liquid | 1 | 8 |

| Piping | Liquid | 2 | 9 |

Example

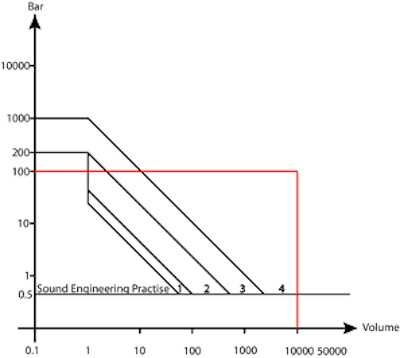

Consider a propane tank with a 10m3 capacity. The maximum allowable pressure of the container is 100 bar (1450 psi). The maximum allowable temperature is 75°C. To find out the PED Category:

- The pressure equipment type is a vessel.

- The state of the fluid is a gas. Propane at the maximum allowable temperature of 75°C (167°F) has a vapor pressure of 28.5 bar absolute pressure. This is higher than 0.5 bar (7.2 psi) above atmospheric pressure. In this case, propane is considered a gas.

- Propane is extremely flammable; as such, it goes in Group 1.

- Table 1 shows that the chart to use is chart number 1.

- The maximum allowable pressure is 100 bar at atmospheric pressure. The tank has a capacity of 10m3, equal to 10,000 liters.

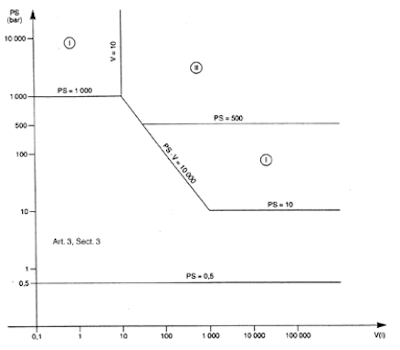

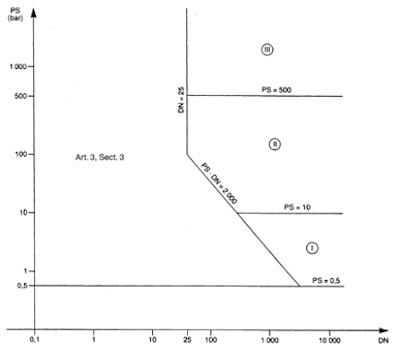

- Use chart number 1 to determine the PED hazard Category. The red line indicates the maximum pressure and volume inside the vessel. Therfore, the vessel is a Category four vessel.

Figure 2: Example of chart 1, with the maximum allowable pressure at 100 bar and the capacity of the tank at 10.000 liters, the vessel comes into Category 4 of the PED hazard Category.

Defining fluid state

As a standard, the fluid state of media within pressure equipment is defined by the vapor pressure at the maximum allowable temperature. If a medium has a vapor pressure more than 0.5 bar (7.25 psi) above atmospheric pressure of 1013 mbar, it is considered a gas. It is considered a liquid should the vapor pressure be lower than 0.5 bar at atmospheric pressure.

The term 'gas' refers to gases dissolved under pressure, gases, liquefied gases, vapors, and liquids when the vapor pressure at maximum permissible temperature is greater than 0.5 bar above atmospheric pressure. All media with a vapor pressure not exceeding 0.5 bar above atmospheric pressure are considered liquids.

Exceptions

In general, the pressure equipment directive charts offer a straightforward way to determine the PED Category. However, there are exceptions to the charts.

- Chart 1: Vessels that fall in Category 1 or 2 based on chart 1, which are used for unstable gases, are categorized in Category 3.

- Chart 2: Portable fire extinguishers and bottle breathing equipment that fall in Category 1 or 2 must at least be classified in Category 3.

- Chart 4: Assemblies intended to generate warm water not exceeding 110°C, manually fired with fuels that are solid, have pressure and volume greater than 50 bar liters, should be inspected according to the EC design inspection guidelines or a complete quality assurance.

- Chart 5: Pressure cookers are required to undergo a conformity procedure to a minimum of one of the Category three modules as found in Directive 97/23/EC of the European Union.

- Chart 6: Piping used for gases that are considered unstable, falling within categories 1 or 2 based on chart 6, should be placed in Category 3.

- Chart 7: Piping containing fluids at a temperature greater than 350°C and falling into Category 2 according to chart 7 must be categorized as Category 3.

Category charts

Below are the nine charts of the pressure equipment directive; use these to determine the correct Category.

Chart 1

Figure 3: PED category chart 1

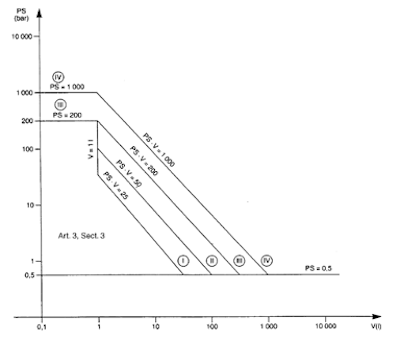

Chart 2

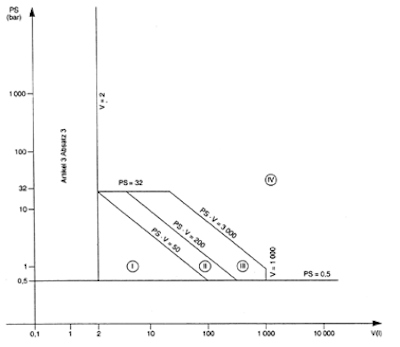

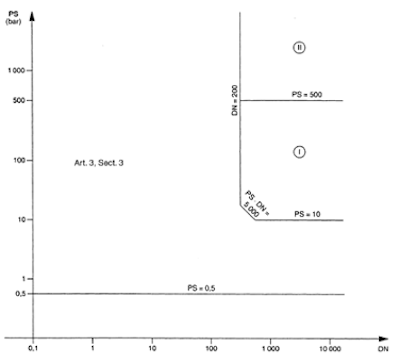

Figure 4: PED category chart 2

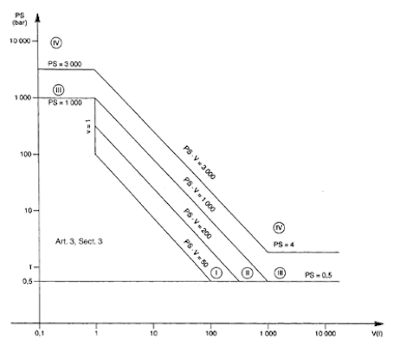

Chart 3

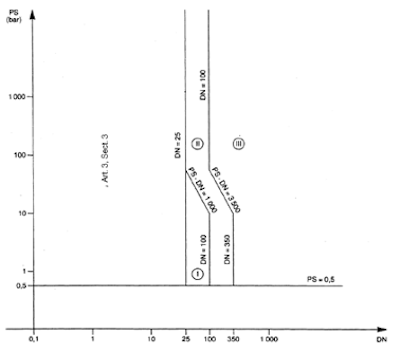

Figure 5: PED category chart 3

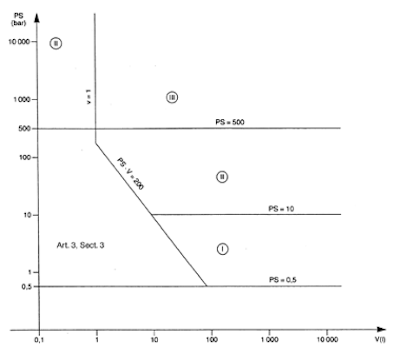

Chart 4

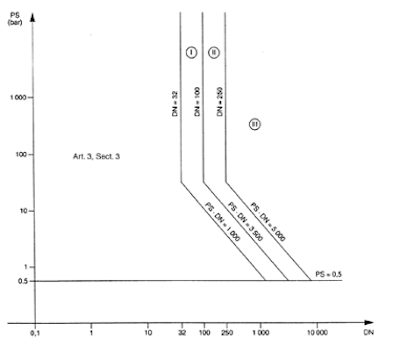

Figure 6: PED category chart 4

Chart 5

Figure 7: PED category chart 5

Chart 6

Figure 8: PED category chart 6

Chart 7

Figure 9: PED category chart 7

Chart 8

Figure 10: PED category chart 8

Chart 9

Figure 11: PED category chart 9