Knife Gate Valve Guide

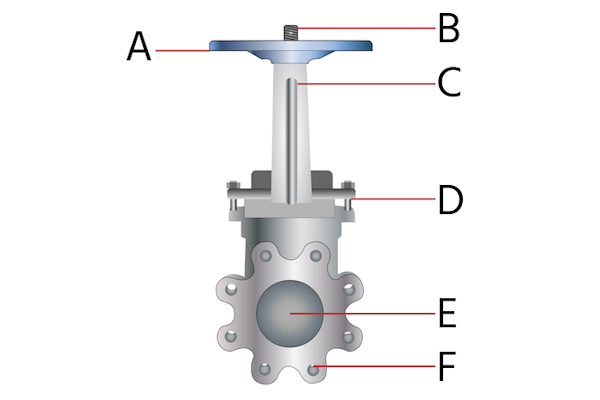

Figure 1: Knife gate valve

Gate valves control the flow of fluids in several industries, for example, water treatment, chemical storage, and oil and gas. These valves have a variety of designs that each have optimal suitability for various applications. This article will focus primarily on the knife gate valve's design, function, and applicability. Read our gate valve article for a more comprehensive understanding of gate valves!

Table of contents

- What is a knife gate valve?

- How a knife gate valve works

- Types of knife gates valves

- Knife gate valve materials

- Knife gate valve standards

- Knife gate valve applications

- FAQs

What is a knife gate valve?

A knife gate valve is suitable for on-off and isolation operations. It is most applicable in systems transporting slurry and media containing suspended solids. The valve has a beveled metal edge that cuts through media, which may block the closure of plug, ball, or other gate valve types.

Figure 2: A knife gate valve with components: handwheel (A), stem (B), yoke (C), packing gland (D), gate (E), and lug nuts (F).

How a knife gate valve works

A knife gate valve is a multi-turn valve, meaning its handwheel must rotate more than 360° to fully open or close the valve. Knife gate valve actuation can also be electrical, pneumatic, or hydraulic. Upon closure, the gate moves into the path of the media. The beveled edge allows the gate to cut through the media, contact the valve seat, and provide a seal. When the gate is fully closed, pressure from the media presses the gate up against the seat, which assists the sealing.

Types of knife gates valves

Knife gate valves are available in various sizes and types for different uses.

Flow direction

Knife gate valves can be unidirectional or bi-directional.

-

Unidirectional

- Metal seated: Metal seated knife gate valves have a Class IV leakage rate, which is acceptable according to MSS standards. This leakage rate translates to 10 mL/inch/min. Pulp and other solids in the media can get blocked in the valve's seal, further helping the valve seal tightly.

- Resilient seated: Resilient seated knife gate valves provide improved sealing using a rubber molded seat.

- Pressure-assisted sealing: Media flowing towards the valve applies pressure to the gate, pressing it against the valve seat.

- Jams assist in sealing: Pulpy and solid materials get stuck to the valve gate when it is closed. These materials help further with sealing the valve.

- Potential guides for gate: The gate periphery may have tabs that support the gate in case of a reverse flow, stopping it from bending.

-

Bi-directional

- Seat: Nearly all bi-directional knife gate valves have resilient seating. The seating is a perimeter seat that provides a dual seating surface using only one seat.

- Sealing: The actuator force, whether manual, hydraulic, or pneumatic, provides the force necessary for sealing. The actuator must maintain its force when the valve is closed to ensure sealing.

- Media: Bi-directional knife gate valves are not suitable for dry media. The dry particles can get stuck between the gate and the perimeter seat.

Urethane lined

Urethane-lined knife gate valves are bi-directional and versatile. The urethane must line the entire valve: the port openings, chest area, and packing area. There are multiple urethane types for different chemicals in media.

Urethane-lined knife gate valves excel in abrasive media applications. However, these valves have a lower temperature limit than other resilient seated valves. For example, a FKM resilient seated valve has a temperature limit of up to 232°C (450°F), whereas a urethane lined valve has a temperature limit of 126°C (260°F).

Other factors

-

Connection type:

- Welded: This connection type involves welding the valve body to the piping. This type is more suitable for high-pressure applications.

- Threaded: This connection type involves threading screws through the valve's flanges to connect with piping. This type is more suitable for low-pressure applications.

-

Stem type:

- Rising: A rising stem moves up and down as the valve opens and closes. This type requires more vertical or horizontal space, depending on the orientation of the valve.

- Non-rising: The stem does not move up and down as the valve opens and closes. An indicator is installed on the valve to show how open or closed the valve is.

Knife gate valve materials

The following material examples are commonplace but not exhaustive. For a comprehensive understanding of material properties, read our chemical resistance guide!

- Urethane lined: Urethane-lined knife gate valves are more expensive, so their bodies typically are cast iron or ductile iron to make them cost-effective.

- Stainless steel body: Stainless steel is relatively expensive but durable and resistant to corrosion and heat.

- Carbon steel body: Carbon steel is strong, long-lasting, and suitable for high-pressure systems.

- Resilient seat: Knife gate valve resilient seats can be a variety of materials, such as NBR, EPDM, or FKM. Understanding the system's pressure and temperature parameters is essential before selecting seating material.

Knife gate valve standards

Knife gate valves are not manufactured to ANSI standards like typical gate valves are but instead are manufactured to TAPPI standards. Two other important manufacturing standards to pay attention to when deciding between knife gate valves are two MSS standards:

- MSS-SP-8 : This design standard applies to approximately 95% of knife gate valve applications. This standard is for all stainless steel, cast, and fabricated bonnetless knife gate valves.

- MSS-SP-151: This standard is for the seat closure and pressure testing of knife gate valves. It covers resilient, non-metallic (e.g., ceramic), and metallic seating.

Knife gate valve applications

Initially, paper and pulp industries used knife gate valves. Today, however, these valves have various uses in different industries. Below are knife gate valve applications:

-

Pulp and paper industry:

- Used in 3-4% pulp stock.

- Used as a shut-off valve.

- Tight shut-off is unnecessary because the pulpy media can assist in sealing.

- Unidirectional, metal seated knife gate valves are suitable and economical.

- Unidirectional, resilient seated knife gate valves are best for users who need immediate, drip dry shut-off.

- Bi-directional, resilient seated knife gate valves are also suitable but not cost-effective.

- Chemical industry: Knife gate valves control flow in mixer pumps, hopper pumps, dry solid bagging, and powdered chemical conveyance.

- Mineral processing industry: Knife gate valves are used in cyclone feeds, liquor heating tanks, tailing thickeners, slurry systems, and concrete tanks.

FAQs

Is a knife gate valve a type of gate valve?

Yes, a knife gate valve is a type of gate valve with a beveled disc that cuts through slurry and other solids in the media flowing through the valve.

What are the major drawbacks of using a knife gate valve?

The valve can be difficult to operate if it is not well maintained. In addition, valve closure may be difficult if the gate is not aligned correctly.

What is the cost of a knife gate valve?

The cost of a knife gate valve varies depending on the size, material, and manufacturer.